Inspection and Maintenance

Standard Practices

SP–3

d. The use of taper gauges is not recommended because the pointed end of the gauge often “bot-

toms” on an internal curved surface before an accurate reading can be obtained. This gauge

should not be used to take radial clearances.

e. Never rotate the unit rotor when the unit is undergoing inspection and maintenance checks with-

out adhering to the below listed precautions.

(1) Thrust bearing must be fully assembled in unit.

(2) Lubricant from unit lube system should be applied to journals.

(3) Check close clearance areas for potential interference and foreign object damage.

(4) Warn personnel working on unit.

16. To properly tighten new Swagelock stop-collar fittings, snug the nut by hand after cleaning threads.

Then tighten the nut until the stop-collar just stops turning.

17. Anti-Seize Compound

a. Anti-seize compound shall be applied on all rotor and stator bolting threads, dowels, rabbets

and sliding fits (internal and external).

External bolting threads for mounting associated equipment, pipe flanges, ductwork etc. Also

apply on vertical flange faces of the top halves of outer casings that may be subject to removal

for maintenance.

Note:

This usage must be restricted to a thin film such that the compound

is not forced into the inner gas path. Should this occur, it must where

possible, be carefully removed.

b. Do not apply anti-seize compound to pipe threads or bolting threads internal to oil or water tanks.

18. Sealing Compound

a. Loctite Pipe Sealant with Teflon should be used on all pipe thread joints. The pipe thread must

be clean and free of foreign material before applying the sealant. Follow instructions on container.

b. Loctite Pipe Sealant with Teflon is to be used on all threaded connections to cast iron castings,

after control filters, and in areas over 500

°

F.

Apply to the male threads so that the first thread is free of any compound.

When a fitting is removed, the female threads shall be cleaned to remove all loose particles of

compound.

19. Joint Compound

a. Joint compound shall not be used on machined joints except as follows:

(1) For compressor and turbine casings apply Perfect Seal only on the surface of horizontal joint

and only for a distance of one (1) inch on both sides of the four (4) way joint. The Perfect

Seal shall not be applied on the surface of the vertical joint.

Содержание MS6001B

Страница 2: ...Gas Turbine Inspection and Maintenance GEK 107048 I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 4: ...Inspection and Maintenance Note THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 12: ...Inspection and Maintenance Notes Cautions and Warnings viii THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 13: ...INSERT TAB INTRODUCTION ...

Страница 14: ......

Страница 25: ...INSERT TAB STANDARD PRACTICES ...

Страница 26: ......

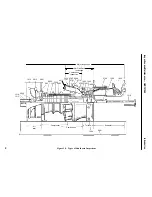

Страница 57: ...Standard Practices Inspection and Maintenance GEK 107048 SP 31 Figure 2 26 Rail Fabrication Hoist ...

Страница 58: ...Inspection and Maintenance GEK 107048 Standard Practices SP 32 Figure 2 27 Pulley Nozzle Segments ...

Страница 59: ...Standard Practices Inspection and Maintenance GEK 107048 SP 33 Figure 2 28 Typical Borescope Kit ...

Страница 60: ...Inspection and Maintenance GEK 107048 Standard Practices SP 34 Figure 2 29 Rail Channel Trolley ...

Страница 61: ...Standard Practices Inspection and Maintenance GEK 107048 SP 35 Figure 2 30 Lifting Beam Inlet Silencer ...

Страница 62: ...Inspection and Maintenance GEK 107048 Standard Practices SP 36 Figure 2 31 Lifting Beam Inlet Transition ...

Страница 63: ...Standard Practices Inspection and Maintenance GEK 107048 SP 37 Figure 2 32 Lifting Beam Inlet Elbow ...

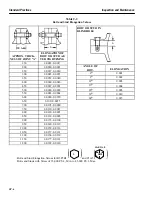

Страница 66: ...Inspection and Maintenance GEK 107048 Standard Practices SP 40 Figure 2 38 Tubing Insert and Male Connector ...

Страница 86: ...Inspection and Maintenance GEK 107048 Standard Practices SP 60 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 87: ...INSERT TAB AUXILIARY CONTROLS SYSTEMS MAINTENANCE ...

Страница 88: ......

Страница 90: ...Auxiliary and Controls Systems Maintenance Inspection and Maintenance THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 104: ...Auxiliary and Controls Systems Maintenance Inspection and Maintenance ACSM 14 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 106: ...Inspection and Maintenance Procedures Inspection and Maintenance I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 132: ...Inspection and Maintenance Procedures Inspection and Maintenance IMP 26 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 133: ...INSERT TAB SCHEDULED TURBINE MAINTENACE ...

Страница 134: ......

Страница 153: ...Scheduled Turbine Maintenance Inspection and Maintenance GEK 107048 STM 19 Figure 4 2 Borescope Light Supply ...

Страница 156: ...Inspection and Maintenance GEK 107048 Scheduled Turbine Maintenance STM 22 Figure 4 5 TV Monitor Presentation ...

Страница 157: ...INSERT TAB COMBUSTION INSPECTION ...

Страница 158: ......

Страница 160: ...Inspection and Maintenance GEK 107048 Combustion Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 239: ...INSERT TAB HOT GAS PATH INSPECTION ...

Страница 240: ......

Страница 242: ...Inspection and Maintenance GEK 107048 Hot Gas Path Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 313: ...INSERT TAB MAJOR INSPECTION ...

Страница 314: ......

Страница 316: ...Inspection and Maintenance GEK 107048 Major Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 350: ...Inspection and Maintenance GEK 107048 Major Inspection Inspection Procedures MI I 8 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 363: ...INSERT TAB MAINTENANCE FORMS ...

Страница 364: ......

Страница 370: ...Inspection and Maintenance GEK 107048 Maintenance Forms MF 6 THIS PAGE INTENTIONALLY LEFT BLANK ...