Inspection and Maintenance — GEK 107048

Combustion Inspection — Inspection Procedures

CI-I-8

9. The outer tip should be examined for orifice damage. The part should be replaced if the orifice is

dented or in any way distorted.

Operation 2 — How to Reassemble the Primary Fuel Nozzles

1. Since plastic coverings are often used to protect the surfaces of new or spare parts, be sure that

all plastic material is removed before reassembling the nozzle. Ensure that no plastic material re-

mains lodged on inside surfaces.

2. Do not use Teflon tape or liquid sealant anywhere in the fuel nozzle assembly.

3. Ensure that all gaskets are new. NEVER REUSE AN OLD GASKET.

4. Use FEL-PRO C-102 anti-seize compound on all threaded parts.

5. During reassembly of the fuel nozzle, use the torque values specified on the fuel nozzle assembly

drawing in the Parts Lists and Drawings volume of the Service Manual.

6. Use a torque wrench with a range from zero to approximately 20 percent above the maximum

torque required for assembly. The accuracy should be within

±

5 percent.

7. Wipe anti-seize compound lightly on the threads of each outer tip and on the corresponding threads

in the fuel nozzle body.

Effective Area Check of Primary Fuel Nozzle Gas Passage

1. The primary gas nozzle effective areas must be compared on an end cover to end cover basis. New

and reconditioned fuel nozzle assemblies are tested as defined on the fuel nozzle assembly draw-

ing in the Parts Lists and Drawings Volume of the Service Manual.

2. If the customer wishes to do this testing, a procedure can be supplied by the GE field representa-

tive.

Storing the Primary Fuel Nozzle

1. Serviceable fuel nozzles should be maintained as complete assemblies in separate containers de-

signed to prevent damage to nozzles during storage. If the fuel nozzles are to be stored for an indef-

inite time, it is recommended that they be sprayed with oil prior to storage.

Operation 3 — How to Disassemble and Inspect Secondary Fuel Nozzles

Disassemble the Secondary Fuel Nozzle

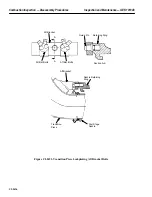

1. Using a strap wrench, unscrew the outer gas tip from the assembly by overriding the lockplate.

2. Identify the outer tip and discard the locking ring.

3. Using a socket or box wrench, remove the transition piece assembly by again overriding the lock-

plate. Identify the part and discard the locking ring and the metal “O” ring seal.

Содержание MS6001B

Страница 2: ...Gas Turbine Inspection and Maintenance GEK 107048 I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 4: ...Inspection and Maintenance Note THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 12: ...Inspection and Maintenance Notes Cautions and Warnings viii THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 13: ...INSERT TAB INTRODUCTION ...

Страница 14: ......

Страница 25: ...INSERT TAB STANDARD PRACTICES ...

Страница 26: ......

Страница 57: ...Standard Practices Inspection and Maintenance GEK 107048 SP 31 Figure 2 26 Rail Fabrication Hoist ...

Страница 58: ...Inspection and Maintenance GEK 107048 Standard Practices SP 32 Figure 2 27 Pulley Nozzle Segments ...

Страница 59: ...Standard Practices Inspection and Maintenance GEK 107048 SP 33 Figure 2 28 Typical Borescope Kit ...

Страница 60: ...Inspection and Maintenance GEK 107048 Standard Practices SP 34 Figure 2 29 Rail Channel Trolley ...

Страница 61: ...Standard Practices Inspection and Maintenance GEK 107048 SP 35 Figure 2 30 Lifting Beam Inlet Silencer ...

Страница 62: ...Inspection and Maintenance GEK 107048 Standard Practices SP 36 Figure 2 31 Lifting Beam Inlet Transition ...

Страница 63: ...Standard Practices Inspection and Maintenance GEK 107048 SP 37 Figure 2 32 Lifting Beam Inlet Elbow ...

Страница 66: ...Inspection and Maintenance GEK 107048 Standard Practices SP 40 Figure 2 38 Tubing Insert and Male Connector ...

Страница 86: ...Inspection and Maintenance GEK 107048 Standard Practices SP 60 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 87: ...INSERT TAB AUXILIARY CONTROLS SYSTEMS MAINTENANCE ...

Страница 88: ......

Страница 90: ...Auxiliary and Controls Systems Maintenance Inspection and Maintenance THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 104: ...Auxiliary and Controls Systems Maintenance Inspection and Maintenance ACSM 14 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 106: ...Inspection and Maintenance Procedures Inspection and Maintenance I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 132: ...Inspection and Maintenance Procedures Inspection and Maintenance IMP 26 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 133: ...INSERT TAB SCHEDULED TURBINE MAINTENACE ...

Страница 134: ......

Страница 153: ...Scheduled Turbine Maintenance Inspection and Maintenance GEK 107048 STM 19 Figure 4 2 Borescope Light Supply ...

Страница 156: ...Inspection and Maintenance GEK 107048 Scheduled Turbine Maintenance STM 22 Figure 4 5 TV Monitor Presentation ...

Страница 157: ...INSERT TAB COMBUSTION INSPECTION ...

Страница 158: ......

Страница 160: ...Inspection and Maintenance GEK 107048 Combustion Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 239: ...INSERT TAB HOT GAS PATH INSPECTION ...

Страница 240: ......

Страница 242: ...Inspection and Maintenance GEK 107048 Hot Gas Path Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 313: ...INSERT TAB MAJOR INSPECTION ...

Страница 314: ......

Страница 316: ...Inspection and Maintenance GEK 107048 Major Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 350: ...Inspection and Maintenance GEK 107048 Major Inspection Inspection Procedures MI I 8 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 363: ...INSERT TAB MAINTENANCE FORMS ...

Страница 364: ......

Страница 370: ...Inspection and Maintenance GEK 107048 Maintenance Forms MF 6 THIS PAGE INTENTIONALLY LEFT BLANK ...