4-188

Range

0.00~10.00 Sec

Duration of DC injection braking during a start operation. DC injection braking at start is disabled when parameter

07-16 is set to 0 sec.

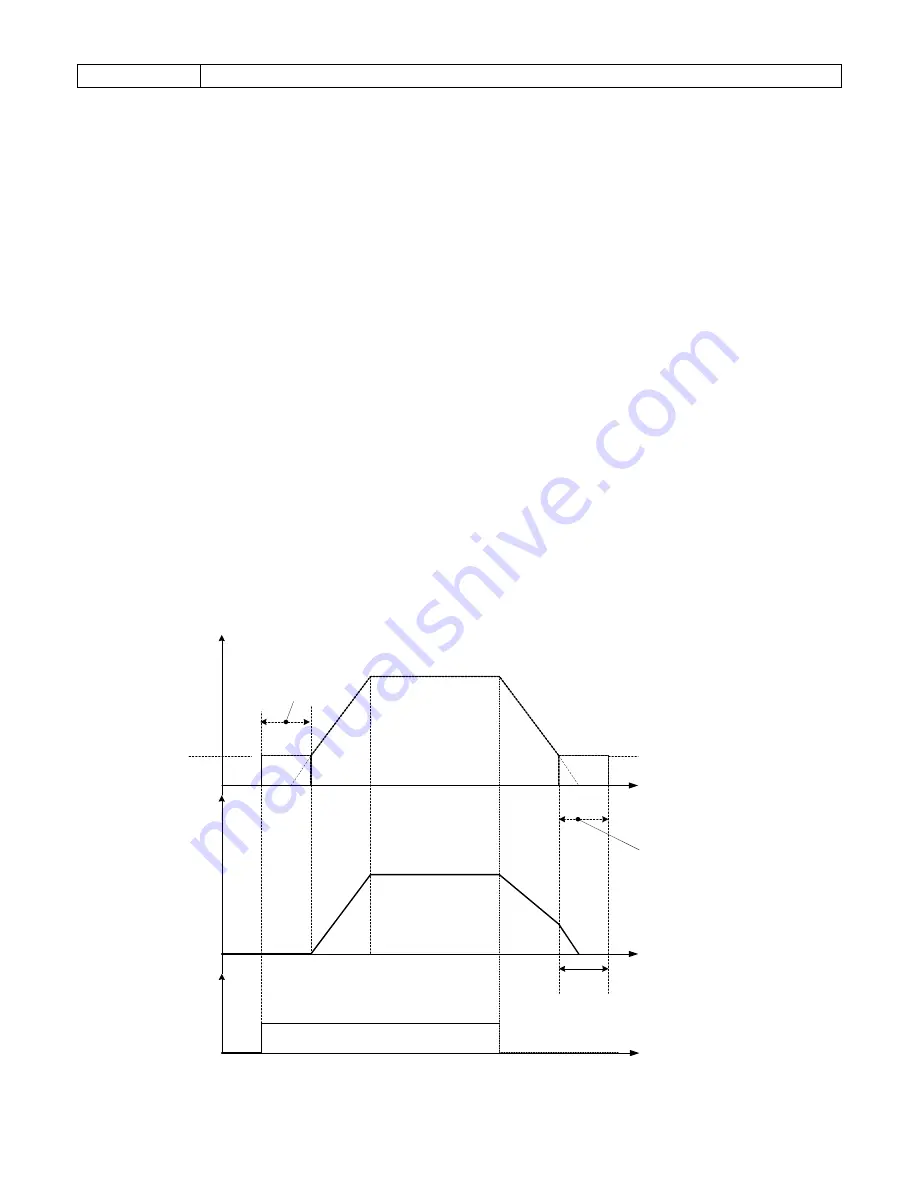

DC Injection Braking Operation

When DC Injection braking is active DC voltage is applied to the motor, increasing the braking current and

resulting in an increase in the strength of the magnetic field trying to lock the motor shaft.

To enable DC injection braking during a start operation set the DC injection braking current (07-07) and the DC

injection braking time (07-16) at start to a value greater than 0. DC injection braking at start can be used to

prevent “wind milling effect” in fan applications.

To enable DC injection braking during a stop operation set the DC injection braking current (07-07) and the DC

injection braking time at stop (07-08) to a value greater than 0.

Notes:

- When parameter 07-16 is set to 0 sec. the inverter will start from the minimum output frequency.

- Increasing the DC braking time (07-08, 07-16) can reduce the motor stop time.

- Increasing the DC braking current (07-07) can reduce the motor stop time.

- During stop operation: If the DC braking start frequency < minimum output frequency (01-08), DC braking

is activated when the output frequency reaches the minimum output frequency level.

- DC Injection braking cannot be used in sensor vector control (SV).

For DC braking operation, please refer to Figure 4.4.57.

t

07-06

07-08

07-16

01-08

(Fmin)

Braking

time

The larger value of

01-08 or 07-06

Output

Frequency

Motor

Speed

Run

Command

t

t

Figure 4.4.57 DC braking operation