6. OPTION

6.7 Connector Conversion Box

6 - 11

1

OV

ER

VI

EW

2

SY

STEM

CONFIGURA

TION

3

SP

ECI

F

IC

A

T

IO

NS

4

PA

R

T

S

N

A

M

E

5

UL, c

U

L

S

TANDARDS

A

N

D

E

MC

DIRECTIVE

6

OP

TIO

N

7

INST

ALL

A

TI

ON

8

COMMUNICA

TION

CABLE

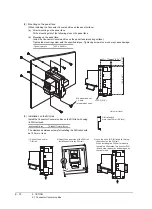

Installation (GT16H-CNB-42S)

The Connector Conversion Box can be installed on the panel face directly or on the DIN rail.

(1) Mounting on the panel face

(When setting the connector for Handy GOT connection and the power supply switch on the panel surface)

(a) Direct mounting on the panel face

Drill a mounting slot of the

following size on the panel

face.

(b) Installation of the packing

Install the accessory packing to the packing attachment

chase of the Connector Conversion Box.

Be sure to install the packing.

(c) Mounting on the panel face

Fit the Connector Conversion Box from the back side of the panel face, and fix it with four M4 screws

(prepared by user).

In the Connector Conversion Box, thread of M4, 6 mm in depth is cut in each mounting hole.

Prepare four M4 mounting screws separately while considering the thickness of the panel face.

Tighten the mounting screw with the specified torque. Tightening screws too much may cause damage.

Make sure that interfering objects are not located within 65 mm from the rear face so that the connector of

a PLC cable is not hindered.

To wire the terminal block, keep a space of 25 mm or more on both sides of the Connector Conversion Box.

Tightening torque

0.69 to 0.88 N•m

Drill 4- 5±0.5 (0.2

"±0.02")

Panel cut area

Unit: mm (inch)

61+1,-0 (2.41

"±0.04",-0)

(Panel opening)

77±0.5 (3.04

"±0.02")

85±0.5 (3.35

"±0.02

")

87+1,-0 (3.43"+0.04",-0)

(Panel opening)

4-R3 max (Panel opening)

Packing attachment chase

Elevation view

Unit: mm (inch)

ON

ID No.

ES1A

ES2A ES2B ES3A ES3B

FG

ES1B

U

RS-232

10BASE-T

100BASE-TX

RS-422

L

OFF

ES1A

ES2A ES2B ES3A ES3B

-INPUT 24VDC+

ES1B

SW-COM

SW6

SW4

KSW1 DSW1 DSW2

SW2

SW1

SW5

KSW2

KSW-COM

DSW1 DSW2

SW3

65 (2.56

")

25 (0.99

")

25 (0.99

")

Summary of Contents for GT16

Page 1: ......

Page 2: ......

Page 46: ...1 4 1 OVERVIEW 1 1 Features ...

Page 54: ...2 8 2 SYSTEM CONFIGURATION 2 2 System Equipment ...

Page 60: ...3 6 3 SPECIFICATIONS 3 4 Battery specifications ...

Page 72: ...5 8 5 UL cUL STANDARDS AND EMC DIRECTIVE 5 2 EMC Directive ...

Page 102: ...6 30 6 OPTION 6 7 Connector Conversion Box ...

Page 106: ...7 4 7 INSTALLATION 7 1 Installing Procedure ...

Page 110: ...8 4 8 COMMUNICATION CABLE 8 1 Overview of Communication Cable ...

Page 130: ...9 20 9 HANDLING OF POWER WIRING AND SWITCH 9 4 Switch Wiring ...

Page 142: ...10 12 10 UTILITY FUNCTION 10 3 Utility Display ...

Page 184: ...11 42 11 DISPLAY AND OPERATION SETTINGS GOT SET UP 11 4 Maintenance Function ...

Page 202: ...12 18 12 COMMUNICATION INTERFACE SETTING COMMUNICATION SETTING 12 3 Ethernet Setting ...

Page 226: ...13 24 13 DEBUG 13 3 Memory Data Control ...

Page 248: ...14 22 14 SELF CHECK 14 2 Batch Self Check ...

Page 350: ...15 102 15 DATA CONTROL 15 3 OS Project Information ...

Page 410: ...19 22 19 TROUBLESHOOTING 19 2 Error Message and System Alarm ...

Page 418: ...App 8 APPENDICES Appendix 3 Transportation Precautions ...

Page 422: ...REVISIONS 4 ...

Page 425: ......

Page 426: ......

Page 427: ......

Page 428: ......

Page 470: ......

Page 510: ...21 22 21 COMPUTER LINK CONNECTION 21 6 Precautions ...

Page 568: ...22 58 22 ETHERNET CONNECTION 22 5 Precautions ...

Page 584: ......

Page 626: ...25 14 25 SERVO AMPLIFIER CONNECTION 25 7 Precautions ...

Page 632: ...26 6 26 ROBOT CONTROLLER CONNECTION 26 6 Precautions ...

Page 647: ...MULTIPLE GOT CONNECTIONS 29 GOT MULTI DROP CONNECTION 29 1 ...

Page 648: ......

Page 659: ...MULTI CHANNEL FUNCTION 30 MULTI CHANNEL FUNCTION 30 1 ...

Page 660: ......

Page 675: ...FA TRANSPARENT FUNCTION 31 FA TRANSPARENT FUNCTION 31 1 ...

Page 676: ......

Page 742: ...31 66 31 FA TRANSPARENT FUNCTION 31 7 Precautions ...

Page 744: ......

Page 766: ...32 22 32 CONNECTION TO IAI ROBOT CONTROLLER 32 7 Precautions ...

Page 802: ...34 10 34 CONNECTION TO OMRON TEMPERATURE CONTROLLER 34 7 Precautions ...

Page 834: ...36 18 36 CONNECTION TO KOYO EI PLC 36 6 Device Range that Can Be Set ...

Page 858: ...38 12 38 CONNECTION TO SHARP PLC 38 6 Device Range that Can Be Set ...

Page 868: ...39 10 39 CONNECTION TO SHINKO TECHNOS INDICATING CONTROLLER 39 7 Precautions ...

Page 902: ...42 6 42 CONNECTION TO TOSHIBA MACHINE PLC 42 6 Device Range that Can Be Set ...

Page 908: ...43 6 43 CONNECTION TO PANASONIC SERVO AMPLIFIER 43 7 Precautions ...

Page 970: ...48 12 48 CONNECTION TO FUJI TEMPERATURE CONTROLLER 48 7 Precautions ...

Page 1052: ...52 26 52 CONNECTION TO AZBIL CONTROL EQUIPMENT 52 7 Precautions ...

Page 1102: ...55 14 55 CONNECTION TO GE PLC 55 7 Precautions ...

Page 1114: ...57 4 57 CONNECTION TO SICK SAFETY CONTROLLER 57 5 Device Range that Can Be Set ...

Page 1128: ...59 2 59 CONNECTION TO HIRATA CORPORATION HNC CONTROLLER ...

Page 1130: ...60 2 60 CONNECTION TO MURATEC CONTROLLER ...

Page 1132: ......

Page 1270: ...62 68 62 MICROCOMPUTER CONNECTION ETHERNET 62 8 Precautions ...

Page 1271: ...MODBUS CONNECTIONS 63 MODBUS R RTU CONNECTION 63 1 64 MODBUS R TCP CONNECTION 64 1 ...

Page 1272: ......

Page 1292: ...64 12 64 MODBUS R TCP CONNECTION 64 7 Precautions ...

Page 1293: ...CONNECTIONS TO PERIPHERAL EQUIPMENT 65 VNC R SERVER CONNECTION 65 1 ...

Page 1294: ......

Page 1298: ...65 4 65 VNC R SERVER CONNECTION 65 4 Setting in Personal Computer ...

Page 1302: ...REVISIONS 4 ...

Page 1305: ......

Page 1306: ......