50. CONNECTION TO YOKOGAWA PLC

50.2 Serial Connection

50 - 13

44

CO

NNECTIO

N T

O

PAN

ASONIC

IND

U

STRIAL

DEV

IC

ES SUNX PLC

45

CONNECTION T

O

HIT

A

CHI IES

PL

C

46

CONNECTION T

O

HIT

A

CHI P

L

C

47

CONNE

C

T

ION T

O

FUJI

P

L

C

48

CO

NN

EC

TI

O

N T

O

FU

JI

T

E

M

P

E

R

A

T

UR

E

CO

NT

RO

LL

E

R

49

CONNECTION

T

O

Y

A

SKA

W

A

PL

C

50

C

O

NNECTION T

O

YOK

OGA

W

A

PL

C

51

CON

NECT

IO

N T

O

YO

KO

G

AW

A T

EMP

ERA

TUR

E

CON

TROLLE

R

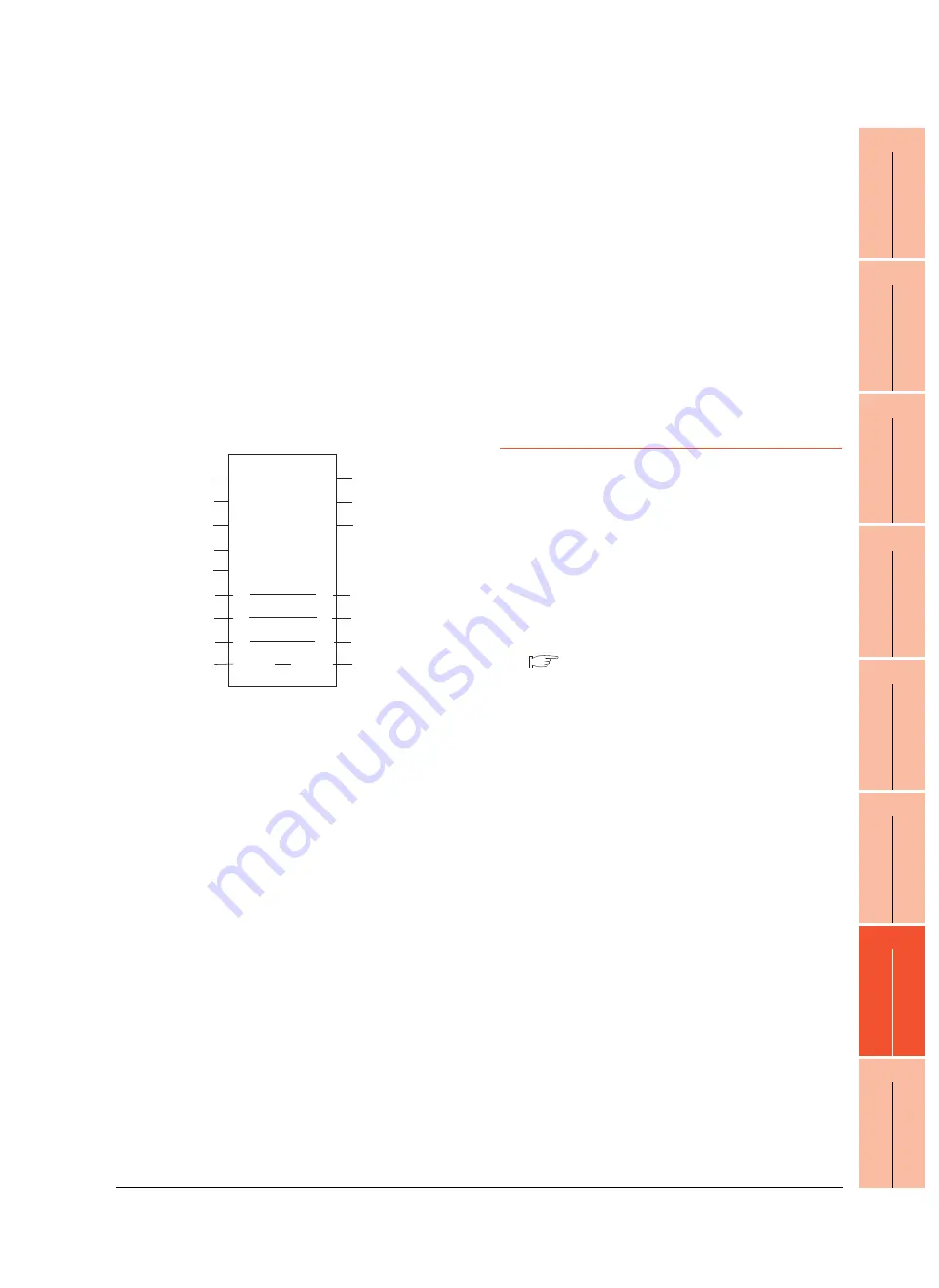

4.

Copy a sample project POU to the new project.

(1) Open C{Install

Folder}\LogicDesigner\Projects\EXAMPLE_J.mwt.

(2) Right-click [FAM3_Emulator] in the Logic POU

under the project tree in the Example_J project,

and select [Copy].

(3) Right-click the [Logic POU] under the project tree

in the created new project, and select [Paste].

(4) Double-click the [FAM3_Emulator*] file in the

[FAM3_Emulator*] folder.

(5) For the following terminals, set as shown below.

REQ terminal

: TRUE

TERMCHAR terminal : FALSE

PORT terminal

: COM1

STATION terminal

: STATION1

5.

Defining the instance

Instantiate Logic POU. Define an already defined

instance to Task0.

(1) Right-click the [Physical

hardware][Configuration:IPC_33/FCX01:FCX/

Tasks/Task0:CYCLIC] and select [Insert] -

[Program instance].

(2) Define the program instance name and select

FAM3_Emulator for the program type.

6.

Defining Target Setting

Define the IP address or host name of STARDOM for

which the communication settings are made.

Double-click [Physical

hardware][Configuration:IPC_33/FCX01:FCX/Target

Setting] and input the IP address or the host name.

7.

Downloading the project

(1) Execute [Build] – [Make]. (Same as when pressing

the function key F9).

(2) Download after confirming that the compile error

does not occur.Select [Download] in the project

control dialog displayed when [Online] – [Project

control] is selected.

(3) When the download is completed, select [Cold]

and start STARDOM.

50.2.12 Precautions

Device range

When performing monitoring with the GOT connected

to a YOKOGAWA PLC and setting devices for objects,

use devices within the device range of the

YOKOGAWA PLC.

When a device outside the range is set on an object, an

indefinite value is displayed on the object.

(No error is displayed in the system alarm.)

For details on the device range of YOKOGAWA PLCs,

refer to the following:

50.4 Device Range that Can Be Set

Connecting to STARDOM

(1) Redundant system

When STARDOM is configured with a redundant

system, the connection is not supported.

(2) System alarm

The PLC error does not appear in the system alarm.

(3) GOT clock control

Since the STARDOM does not have a clock function,

the settings of [time adjusting] or [time broad cast] by

GOT clock control will be disabled.

TRUE

REQ

VALID

VALID1

ERROR

ERROR1

STATUS1

STATUS

I

D

D

B

B

STATION1

STATION

I

D

D

B

B

I

FALSE

PORT

(Definition example of Logic POU)

TERMCHAR

COMERR1

COMERR

COMERR

COMERR1

COM1

CHECKSUM

SD_CFAM3R_OPEN_COM1

SD_CFAM3R_OPEN

(*VALID*)

(*COM1*)

FALSE

I

Summary of Contents for GT16

Page 1: ......

Page 2: ......

Page 46: ...1 4 1 OVERVIEW 1 1 Features ...

Page 54: ...2 8 2 SYSTEM CONFIGURATION 2 2 System Equipment ...

Page 60: ...3 6 3 SPECIFICATIONS 3 4 Battery specifications ...

Page 72: ...5 8 5 UL cUL STANDARDS AND EMC DIRECTIVE 5 2 EMC Directive ...

Page 102: ...6 30 6 OPTION 6 7 Connector Conversion Box ...

Page 106: ...7 4 7 INSTALLATION 7 1 Installing Procedure ...

Page 110: ...8 4 8 COMMUNICATION CABLE 8 1 Overview of Communication Cable ...

Page 130: ...9 20 9 HANDLING OF POWER WIRING AND SWITCH 9 4 Switch Wiring ...

Page 142: ...10 12 10 UTILITY FUNCTION 10 3 Utility Display ...

Page 184: ...11 42 11 DISPLAY AND OPERATION SETTINGS GOT SET UP 11 4 Maintenance Function ...

Page 202: ...12 18 12 COMMUNICATION INTERFACE SETTING COMMUNICATION SETTING 12 3 Ethernet Setting ...

Page 226: ...13 24 13 DEBUG 13 3 Memory Data Control ...

Page 248: ...14 22 14 SELF CHECK 14 2 Batch Self Check ...

Page 350: ...15 102 15 DATA CONTROL 15 3 OS Project Information ...

Page 410: ...19 22 19 TROUBLESHOOTING 19 2 Error Message and System Alarm ...

Page 418: ...App 8 APPENDICES Appendix 3 Transportation Precautions ...

Page 422: ...REVISIONS 4 ...

Page 425: ......

Page 426: ......

Page 427: ......

Page 428: ......

Page 470: ......

Page 510: ...21 22 21 COMPUTER LINK CONNECTION 21 6 Precautions ...

Page 568: ...22 58 22 ETHERNET CONNECTION 22 5 Precautions ...

Page 584: ......

Page 626: ...25 14 25 SERVO AMPLIFIER CONNECTION 25 7 Precautions ...

Page 632: ...26 6 26 ROBOT CONTROLLER CONNECTION 26 6 Precautions ...

Page 647: ...MULTIPLE GOT CONNECTIONS 29 GOT MULTI DROP CONNECTION 29 1 ...

Page 648: ......

Page 659: ...MULTI CHANNEL FUNCTION 30 MULTI CHANNEL FUNCTION 30 1 ...

Page 660: ......

Page 675: ...FA TRANSPARENT FUNCTION 31 FA TRANSPARENT FUNCTION 31 1 ...

Page 676: ......

Page 742: ...31 66 31 FA TRANSPARENT FUNCTION 31 7 Precautions ...

Page 744: ......

Page 766: ...32 22 32 CONNECTION TO IAI ROBOT CONTROLLER 32 7 Precautions ...

Page 802: ...34 10 34 CONNECTION TO OMRON TEMPERATURE CONTROLLER 34 7 Precautions ...

Page 834: ...36 18 36 CONNECTION TO KOYO EI PLC 36 6 Device Range that Can Be Set ...

Page 858: ...38 12 38 CONNECTION TO SHARP PLC 38 6 Device Range that Can Be Set ...

Page 868: ...39 10 39 CONNECTION TO SHINKO TECHNOS INDICATING CONTROLLER 39 7 Precautions ...

Page 902: ...42 6 42 CONNECTION TO TOSHIBA MACHINE PLC 42 6 Device Range that Can Be Set ...

Page 908: ...43 6 43 CONNECTION TO PANASONIC SERVO AMPLIFIER 43 7 Precautions ...

Page 970: ...48 12 48 CONNECTION TO FUJI TEMPERATURE CONTROLLER 48 7 Precautions ...

Page 1052: ...52 26 52 CONNECTION TO AZBIL CONTROL EQUIPMENT 52 7 Precautions ...

Page 1102: ...55 14 55 CONNECTION TO GE PLC 55 7 Precautions ...

Page 1114: ...57 4 57 CONNECTION TO SICK SAFETY CONTROLLER 57 5 Device Range that Can Be Set ...

Page 1128: ...59 2 59 CONNECTION TO HIRATA CORPORATION HNC CONTROLLER ...

Page 1130: ...60 2 60 CONNECTION TO MURATEC CONTROLLER ...

Page 1132: ......

Page 1270: ...62 68 62 MICROCOMPUTER CONNECTION ETHERNET 62 8 Precautions ...

Page 1271: ...MODBUS CONNECTIONS 63 MODBUS R RTU CONNECTION 63 1 64 MODBUS R TCP CONNECTION 64 1 ...

Page 1272: ......

Page 1292: ...64 12 64 MODBUS R TCP CONNECTION 64 7 Precautions ...

Page 1293: ...CONNECTIONS TO PERIPHERAL EQUIPMENT 65 VNC R SERVER CONNECTION 65 1 ...

Page 1294: ......

Page 1298: ...65 4 65 VNC R SERVER CONNECTION 65 4 Setting in Personal Computer ...

Page 1302: ...REVISIONS 4 ...

Page 1305: ......

Page 1306: ......