2NL/2P8-B

2-2-4

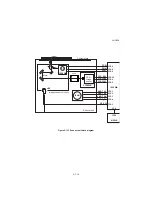

12. Lift sensor 1 (LS1)................................. Detects activation of upper limit of the bottom plate in the cassette

1.

13. Lift sensor 2 (LS2)................................. Detects activation of upper limit of the bottom plate in the cassette

2.

14. Feed sensor 1 (FS1) ............................. Detects a paper misfeed in the vertical conveying section.

15. Feed sensor 2 (FS2) ............................. Detects a paper misfeed in the vertical conveying section.

16. Registration sensor (RS)....................... Controls the secondary paper feed start timing.

17. Eject sensor (ES) .................................. Detects a paper misfeed in the fuser or eject section.

18. Duplex sensor (DUS) ............................ Detects a paper jam in the duplex section.

19. Paper full sensor (PFS)......................... Detects the paper full in the inner tray.

20. Job paper full sensor (JPFS) ................ Detects the paper full in the job separator tray.

21. Job eject papersensor (JEPS) .............. Detects the presence of paper in the job separator.

22. Paper size width switch 1 (PWSW1)..... Detects the width of paper in the cassette 1.

23. Paper size width switch 2 (PWSW2)..... Detects the width of paper in the cassette 2.

24. Paper size length switch 1 (PLSW1) .... Detects the length of paper in the cassette 1.

25. Paper size length switch 2 (PLSW2) .... Detects the length of paper in the cassette 2.

26. Toner container lock sensor (TCLS) ..... Detects the lock of toner in the toner container.

27. Main power switch (MSW) .................... Turns ON/OFF the AC power source.

28. Cassette heater switch (CHSW) ........... Turns ON/OFF the cassette heater power source.

29. Temperature sensor (TEMS)................. Detects the temperature and absolute humidity outside the

machine.

30. Toner sensor (TS) ................................. Detects the amount of toner remaining in the toner container.

31. Waste toner sensor (WTS).................... Detects when the waste toner box is full.

32. Fuser thermistor 1 (FTH1) .................... Detects the heat roller temperature. (contact / edge)

33. Fuser thermistor 2 (FTH2) .................... Detects the heat roller temperature. (noncontact / center)

34. Toner container switch (TCSW) ............ Detects the presence of toner container.

35. MP tray switch (MPTSW)...................... Detects the position of the MP sub tray.

36. MP paper width switch (MPPWSW)...... Detects the width of paper in the MP tray.

37. MP paper length switch (MPPLSW)...... Detects the length of paper in the MP tray.

Summary of Contents for TASKalfa 3010i

Page 10: ...This page is intentionally left blank ...

Page 100: ...2NL 2P8 1 2 76 This page is intentionally left blank ...

Page 286: ...2NL 2P8 1 3 186 This page is intentionally left blank ...

Page 443: ...2NL 2P8 1 5 59 This page is intentionally left blank ...

Page 471: ...2NL 2P8 2 2 8 This page is intentionally left blank ...

Page 532: ...Installation Guide DP 770 B Document processor DP 772 Document processor Installation Guide ...

Page 568: ...DP 773 Document processor Installation Guide ...

Page 594: ...PF 791 500 x 2 Paper feeder Installation Guide ...

Page 602: ...PF 810 3000 sheet deck Installation Guide ...

Page 615: ...DF 791 3000 sheet finisher Installation Guide ...

Page 630: ...DF 770 D 1000 sheet finisher Installation Guide ...

Page 648: ...AK 740 Bridge unit Installation Guide ...

Page 650: ...MT 730 B Mailbox Installation Guide ...

Page 665: ...PH 7A C D Punch unit Installation Guide ...

Page 686: ...DT 730 B Document tray Installation Guide ...

Page 731: ...5 2013 5 302LC56750 01 H F G D D 6 4 3 7 E C D D M4 8 M4 8 M4 8 M4 8 ...

Page 732: ...FAX System W B Installation Guide ...