258

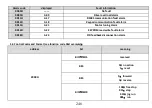

Cooling fan

2

~

3 years

Electrolytic capacitor

4

~

5 years

PCB

5

~

8 years

You should check the driver every 3 months or 6 months according to the actual environment, thus could lower fault risks

and maintain a long-term stable operation.

General Inspection

:

1)

whether screws of control terminals are loose. If so, tighten them with a screwdriver;

2)

whether the main circuit terminals are properly connected; whether the cable or copper bar joints and screws are

over heated;

3)

whether the power cables and control cables are damaged, check especially for any wear on the cable insulation;

4)

whether the connecting of power cable and cold pressing joint is loose, whether the insulating tapes around the

joint are aged or stripped;

5)

clear the dust on PCBs and air ducts, and take anti-static measure;

6)

before performing insulation tests to the driver, dismantle the wiring between the driver and the power supply,

the driver and motor, and all main circuit input/output terminals should be short-circuited with conductors. Then

proceed insulation test to the ground. Please use qualified 500V Mega-Ohm-Meter (or with corresponding voltage

shift of insulation tester); please do not use faulted meter. Insulation test of single main circuit terminal to ground

is prohibited, or the driver can be damaged. After testing, remember to dismantle all the wire that short-circuit

main circuit terminals.

7)

if performing insulation test to the motor, be sure to disconnect the cables between the driver and it. Otherwise,

the driver might be damaged.