−

14

−

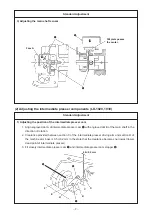

Adjustment Procedures

Results of Improper Adjustment

Adjustment Procedures

Results of Improper Adjustment

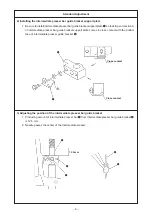

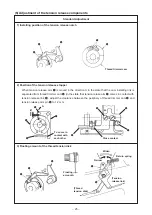

1) Remove the motor cover and remove intermediate presser

lifting spring

2

from intermediate presser lifting spring retainer

1

.

2) Tilt the machine head.

3) Turn the hand pulley to bring the needle bar to its lower dead

point. In this state loosen setscrews

5

and move solenoid

installing base

6

in the direction of

to adjust so that face

A

of plunger

3

is aligned with face

B

of solenoid frame

4

when plunger

3

is lightly pulled in the direction of

←

.

4) Turn the hand pulley to bring the needle bar near its upper

dead point.

5) After the adjustment, hook intermediate presser lifting spring

2

to intermediate presser lifting spring retainer

1

.

*

When hooking internediate presser lifting spring

2

to

intermediate presser lifting spring retainer

1

, protruding

amount of plunger

3

from solenoid frame

4

becomes 15

to 16 mm.

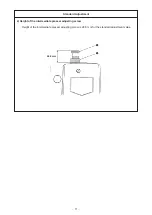

1) Determine the height of the wiper when the needle bar is at its

upper stop position.

Loosen setscrew

1

in the wiper shaft cap and turn the wiper

shaft cap so that the wiper comes almost below the needle.

Then temporarily tighten setscrew

1

.

2) Loosen setscrew

2

and adjust so that clearance provided

between the needle and the wiper should be 1 mm or more.

Then tighten setscrew

2

at the position where the angle of the

wiper is parallel to the needle.

3) Loosen wiper shaft cap setscrew

1

and press down the link

until it hits in the direction of A. Adjust the longitudinal position

to 7 to 8 mm in front of the needle. Adjust the lateral position to

4 to 5 mm from the root of the wiper to the center of the needle.

Then tighten setscrew

1

.

™

If face

A

enters further than face

B

, abnormal noise will occur

when operating the sewing

machine.

™

If the protruding amount is

excessive, the intermediate

presser may not come down at

the time of sewing start.