– 156 –

Troubles

Cause (1)

Cause (2)

Checking order and adjusting method

6. Defective thread trimming

Sharpness of the knife is defective.

Two needle threads are cut. (Short thread waste

remains inside the cylinder arm cap.)

Moving knife does not spread threads.

Stitch skipping at the final stitch.

Bobbin thread is not cut.

Worn-out of the moving and counter knives

Engagement of the moving knife and counter

knives is defective.

Parallel of the blade section of counter knife is

defective.

Attaching position of the counter knife is defective.

There is a burr on thread spreading section

A

of

the moving knife. The shape of thread trimming

becomes and thread waste remains.

Shuttle upper spring has scratches. (The shape

of the thread trimming becomes and thread

waste remains.)

Initial position of the moving knife is maladjusted.

Position of the thread trimmer cam is defective.

Position of the shuttle upper spring is defective.

Clearance between the needle and the inner hook,

and timing of the needle to the inner hook are

defective.

Height of the intermediate presser is too high.

Needle thread loop falls down.

Bobbin thread tension is too low.

Needle hole of the needle hole guide is too large.

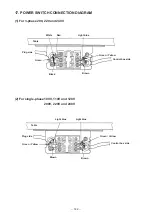

Replace the moving and counter knives.

Properly adjust the height and position of the moving and counter

knives.

Properly adjust the parallel of the blade section of counter knife.

Properly adjust the attaching position of counter knife.

Paying attention to the blade section, polish with polishing powder.

Remove the scratches.

Properly adjust the initial position of moving knife.

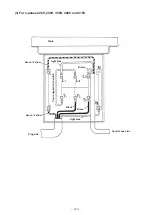

Properly adjust the position of thread trimmer cam.

Properly adjust the position of shuttle upper spring.

Properly adjust the timing abd clearance.

Properly adjust the height of intermediate presser.

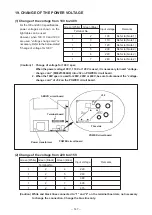

Attach the needle with the long groove orienting slightly to the

right by approximately 20˚.

Stengthen the bobbin thread tension.

Replace the needle hole guide with a new one having a smaller

hole diameter.

A