– 151 –

Troubles

Cause (1)

Cause (2)

Checking order and adjusting method

4. Feeding frame does not go up or come down.

5. Intermediate presser does not come down.

6. Intermediate presser fails to work during sewing.

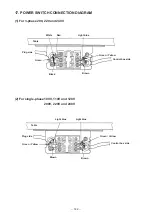

Defective adjustment of the X sensor position

Defective adjustment of the Y slit plate

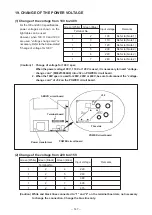

Supply air pressure is low. (Pneumatic type)

Defective adjustment of the regulator (Pneumatic

type)

Contact between the feeding frame and the presser

foot

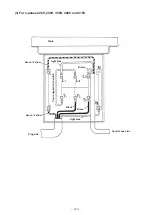

Presser lifter solenoid fails to work properly.

Presser lifter solenoid valve fails to work properly.

Intermediate presser solenoid fails to work properly.

Defective adjustment of the position of the

intermediate presser cam

Whole part of the feeding frame is not pressing

the material to be sewn.

Trouble of the presser lifter solenoid

Defective connection of the presser lifter solenoid

Trouble of the solenoid valve

Defective connection of the solenoid valve

Trouble of the intermediate presser solenoid

Defective connection of the intermediate presser

solenoid

Properly adjust the position of the X sensor.

Properly adjust the position of the sensor slit plate.

Properly adjust the supply air pressure.

Properly adjust the regulator.

Make the pressing shape so as to press uniformly.

Replace the presser lifting solenoid.

Check the connection of the connector.

Replace the solenoid valve.

Check the connection of the connector.

Replace the intermediate presser solenoid.

Check the connection of the connector.

Properly adjust the position of the intermediate presser cam.