−

130

−

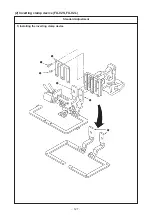

Adjustment Procedures

Results of Improper Adjustment

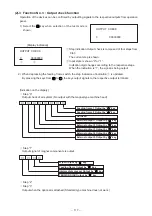

1) When sewing is completed, crank shaft is inverted to the original

state and presser goes up. To prevent interference with needle,

it is recommended to input a point being 10 mm away from the

center of crank shaft as the 2nd origin when creating a pattern.

2) When creating a pattern, and performing input by the optional

inverting, make sure that the number of inverting rotations of

the crank shaft is the odd number.

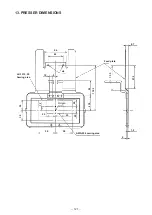

3) It is possible for the inverting clamp device to correspond with

cloth thickness up to 10.1 mm by setting the needle upper

dead point mode with the memory switch.

™

When the number of optional

inverting rotations is the even

number, the crank shaft does not

return to the initial position and

it may come in contact with

needle when sewing causing

needle breakage.