– 154 –

Troubles

Cause (1)

Cause (2)

Checking order and adjusting method

4. Thread breakage

Needle thread loop falls down.

Needle thread loop falls down.

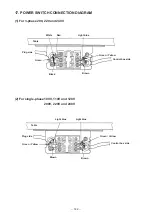

Scratches on the inner hook

Thread enters into the shuttle.

Scratches on the shuttle driver

Clearance between the shuttle driver and the inner

hook is too small.

Scratches on the needle hole guide

Feed timing is too fast.

Scratches on section

A

(Contact of the inner hook

and the needle)

Scratches on section

B

(Scratches occur when

the needle is bent or broken.)

Scratches on section

C

(Needle scratches the

inner hook when removing the inner hook.)

Scratches on section

D

Position of the shuttle upper spring is wrong.

Blade point section

A

of the inner hook is round.

Position of the shuttle is wrong.

Needle thread tension is too low.

Thread take-up spring tension is too low.

Length of the remaining needle thread is too long.

Attach the needle with the long groove orienting slightly to the

right by approximately 20˚.

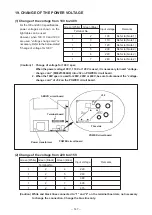

Change the feed timing using the memory switch.

After polishing the blade point of the inner hook with oil-stone,

polish it with polishing powder. Properly adjust the clearance

between the needle and the inner hook.

After polishing the blade point of the inner hook with oil-stone,

polish it with polishing powder.

After polishing the blade point of the inner hook with oil-stone,

polish it with polishing powder.

After polishing the blade point of the inner hook with oil-stone,

polish it with polishing powder.

Properly adjust the position of the shuttle upper spring.

Replace the inner hook.

Properly adjust the position of the shuttle.

Properly adjust the needle thread tension.

Properly adjust the thread take-up spring.

Properly adjust the tension controller No. 1.

Remove the scratches and polish with buff, or replace the shuttle

driver.

Properly adjust the clearance between the shuttle driver and the

inner hook.

Remove the scratches and polish with buff, or replace the needle

hole guide.

A

B

C

D

A