−

34

−

Adjustment Procedures

Results of Improper Adjustment

™

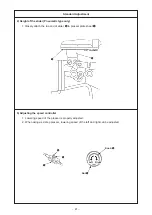

The load of the feed will become

large, causing the failure of the

feed.

™

N o i s e o f f e e d i n g c l o t h i s

increased at the time of sewing

unless the feed plate support

plate is pressed in the

a

direction.

™

The load of the feed will become

large, causing the failure of the

feed or noise.

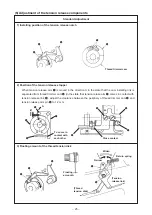

1) Loosen two Y feed arm setscrews

1

.

2) Push Y feed shaft

2

in the direction of arrow

f

.

3) Loosen three setscrews

3

in the feed plate support plate, and

lightly press the feed plate support plate in the

a

direction.

Moving Y feed arm

4

in the

ba

direction making Y feed shaft

2

as a guide, fix feed plate support plate

5

to the position

where there is no torque.

4) Align Y feed shaft

2

with end face A of Y feed arm

4

and

securely tighten Y feed arm setscrews

1

.

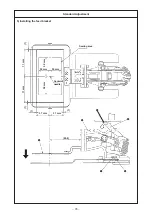

1) Insert feed plate

1

into Y feed support shaft

2

.

2) Enter thrust collar

3

to Y feed support shaft

2

, push feed

plate

1

to feed plate support plate

4

, and remove the thrust.

Then tighten two setscrews

5

.

(Caution) When tightening setscrews

5

, move feed plate

1

in the direction of arrow and tighten the setscrews

so that the position of the setscrews becomes as

shown in Fig. 1.

3) Place square block

6

in the slot portion of feed plate

1

and

insert X feed support shaft

7

into X feed arm

8

.

(Caution) 1. Adjust the flat section to the position of the

screw.

2. The square block

6

is a selective part.

Select a square block which is rather tight

against the slot portion of feed plate

1

.

B1414232000 ...... Loose

B141423200A ..... Medium

B141423200B ..... Tight

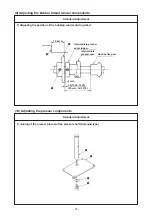

4) Lightly push the flange section of X feed support shaft

7

to

feed plate

1

in the state that a spacer of 0.25 mm is inserted

between feed plate

1

and X slide plate

!0

, and tighten setscrew

9

.