−

24

−

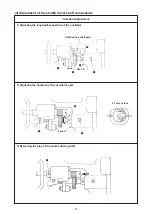

Adjustment Procedures

Results of Improper Adjustment

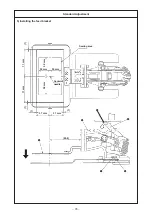

1) Position of the counter knife

Loosen counter knife setscrews

1

to adjust it.

2) Position of the moving knife

Loosen screw

2

to adjust it.

(Caution) Under the normal operation, the moving knife

passes inside the needle hole guide as

A

shown

in the figure.

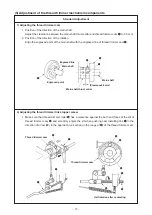

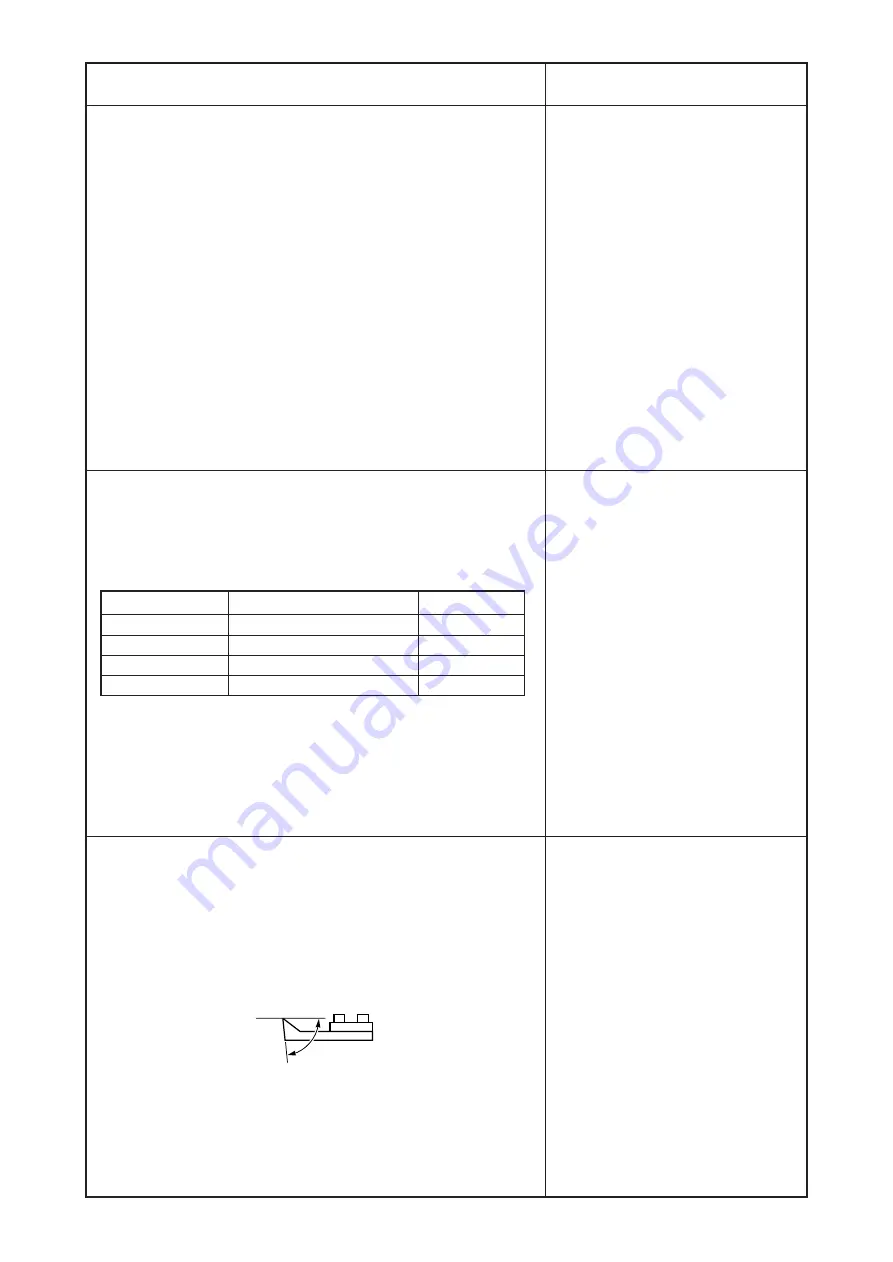

1) Grind side C when the thread on the side B is not cut, and

grind side B when the thread on the side C is not cut.

(Caution) When grinding the side, make the angle more

acuter than 90 degrees.

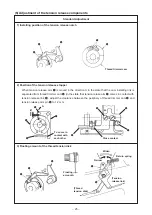

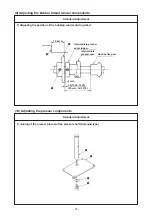

1) Adjusting the height of the moving knife

Adjust the height according to the thickness of the washer

described in the table below when the height is not proper.

Select and use the below-mentioned parts.

2) Adjusting height of the counter knife.

Adjust the height by forcing section

A

with a screwdriver or

the like.

™

When the clearance is 0.5 mm

or less :

When the moving knife pulls

threads, blade point of the

counter knife cuts the threads

and needle/bobbin threads are

cut short.

™

When the clearance is 0.5 mm

or more :

Length of the remaining thread

under the cloth after thread

trimming is lengthened.

™

If the level difference (0.25 to 0.3

mm) between the moving knife

and counter knife is small, it will

cause thread trimming failure.

™

If the level difference (0.1 to 0.15

mm) between the needle hole

guide and the counter knife is

large, when the moving knife

pulls threads, blade point of the

counter knife cuts the threads

and needle/bobbin threads are

cut short.

Acute angle

™

When the slant is less than 0.2 mm

: The thread on side C is not cut.

™

When the slant is more than 0.2 mm

: The thread on side B is not cut.

Part No.

Name of part

Thickness

B242328000A

Moving knife washer

0.4 mm

B242328000B

Moving knife washer

0.5 mm

B242328000C

Moving knife washer

0.6 mm

B242328000D

Moving knife washer

0.7 mm