−

107

−

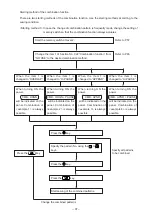

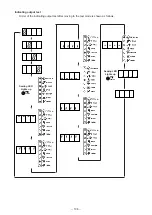

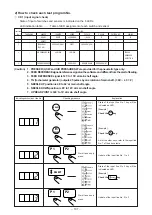

2) How to check each test program No.

1

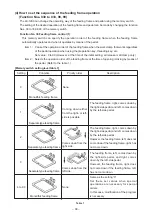

CP-1 (input signal check)

State of input of switches and sensors is indicated on the 8 LEDs.

LED indication table ......... Table of LED assignment of each switch and sensor

Input line

Kind of LED

No.

THREADING

WINDER

COUNTER

SPEED

Y SCALE

X SCALE

PATTERN NO.

SEWING

1

–

READY

RESET

+/ FORWARD

–/ BACK

P1

P2

P3

2

–

SELECT

–

–

–

–

–

–

3

–

PRESSER (R) SW

START

PRESSER (L) SW

–

–

–

4

–

AIR PRESSURE SW

X ORIGIN

Y ORIGIN

–

–

–

5

–

FEED REFERENCE

TG

NEEDLE UP

NEEDLE DOWN

UP DEAD POINT

–

–

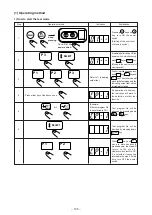

(Caution)

1. PRESSER (L) SW and AIR PRESSURE SW are provided for the pneumatic type only.

2. FEED REFERENCE signal is reference signal on the software and different from the start of feeding.

3. FEED REFERENCE signal is 125˚ to 155˚ at main shaft angle.

4. TG (tachometer generator) outputs 45 pulses by one rotation of main shaft. ( 360˚

÷

45 = 8˚)

5. NEEDLE UP position is 46˚ to 62˚ at main shaft angle.

6. NEEDLE DOWN position is 80˚ to 123˚ at main shaft angle.

7. UP DEAD POINT is 340˚ to 10˚ at main shaft angle.

TEMPORARY

STOP SW

THREAD

BREAKAGE

DETECTION

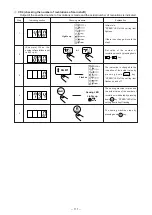

Indicating section (input line No.)

Checking measure

Explanation

READY

RESET

R

P 1

P 2

SELECT

Simultaneously

press.

P 1

P 2

Simultaneously

press.

Update of the input line No. 2 to 3

Check the

SELECT

key.

Update of the input line No. 1 to 2

As for the other keys, refer to the input line

No. 1 of the above table.

State of the input line No. 1 key will be

indicated on LED.

Check the

READY

key.

Check the

RESET

R

key.

State of the input line No. 2 key will be

indicated on LED.

[Example]

[Example]

[Example]