−

26

−

Adjustment Procedures

Results of Improper Adjustment

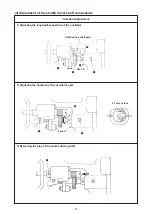

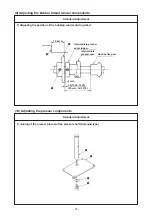

1) Loosen two setscrews

1

in the tension release notch, and

move tension release notch

2

to the center of the long slit.

Then securely tighten two setscrews

1

to fix it.

2) After the adjustment, pushing cam installing link

3

in the

direction of arrow (

f

) by hand, rotate the main shaft in the

normal direction (

a

), and ride tension release pin

4

on tension

release notch

2

. After that, let go of the hand, and make the

main shaft in the normal direction.

Make sure that tension release pin

4

separates from tension

release notch

2

at the position where the thread take-up lever

has passed the upper dead point.

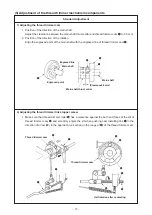

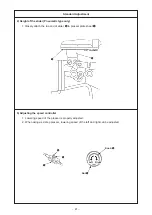

1) Remove tension release return spring

1

.

2) Loosen two setscrews

2

. If the tension release stopper with

tension release adjusting arm closely contacted is pushed in

the direction of arrow (

e

), the learance will be narrowed. If

pushing it in the direction of arrow (

a

), the clearance will be

widened.

3) Adjust the clearance to 1.2 mm, tighten setscrews

2

, and hook

tension release return spring

1

.

4) After the adjustment, tension release arm

7

slightly comes

down in the direction of B by the tare.

Move tension release arm

7

in the direction of A or B and

make sure that there is a play.

(Caution) After adjusting the position of the tension release

stopper, check to be sure of the thread tension disk

floating amount described in the next item 3).

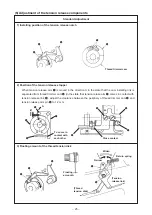

1) Remove the arm cover, and make sure that tension release

pin

3

rides on tension release notch

4

.

2) If the pin does not ride on the notch, push cam installing link

5

by hand in the

e

direction, and rotate the main shaft in the

normal direction to make the state shown in the figure.

3) Under the state shown in the figure, loosen setscrew

2

in the

tension release adjusting arm. Floating amount of the thread

tension disk will vary by moving tension release adjusting arm

1

to the right or left.

Disk floating amount A :

S type : 0.6 to 0.8 mm

H type : 0.8 to 1.0 mm

(Caution) If disk floating amount is too small, the length of

remaining thread after thread trimming will vary. If

the disk floating amount is excessive, disk closing

failure after the release of disk floating will occur.

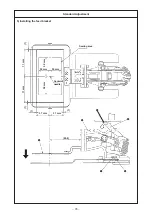

™

If the clearance is excessive,

when adjusting the disk floating

amount to rather excessive, the

disk cannot close completely

when the disk floating is relesed,

causing stitch failure.

™

If the clearance is too small,

malfunction of the thread trimmer

shaft ( a load is produced) will

occur, causing thread trimming

failure or machine lock.

™

Length of remaining needle

thread after thread trimming will

be shortened.

Also, the length will vary.

™

Needle thread may slip off from

the needle at the sewing start.

™

If the disk floating amount is too

samll, the length of remaining

needle thread after thread

trimming will be shortened or the

length will vary to a great extent.

™

If the disk floating amount is

excessive, the disk can not close

completely after the release of

disk floating, causing stitch

failure.