G900X/G950 Installation and Maintenance Manual – Non LRU Specific Installation Information

Page 13-11

190-00719-00

Revision D

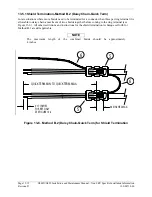

NOTE

Reference Section 13.1.2 for recommended solder sleeves and flat braid. The same

recommendations are applicable to this technique.

Secondary Method:

Solder a Flat Braid (Item 6) to the folded back shield on the prepared cable assembly (Item 4).

Ensure a solid electrical connection through the use of acceptable soldering practices. Use care to

avoid applying excessive heat that burns through the insulation of the center conductors and

shorts the shield to the signal wire. Slide a minimum of 0.75 inches of Teflon heat shrinkable

tubing (Item 5) onto the prepared wire assembly and shrink using a heat gun. The chose size of

heat shrinkage tubing must accommodate both the number of conductors present in the cable as

well as the Flat Braid (Item 6) to be attached.

Teflon Heat Shrinkable Tubing:

Reference the following MIL-Spec for general Teflon heat shrinkable tubing (M23053/5-X-Y)

QUICK TERM MIN. TO QUICK TERM MAX.

6

5

0.17 INCHES

0.35 INCHES MAX OF

SHIELD FOLDED

BACK OVER JACKET

FOR REF. ONLY

SEE FIGURE 13-3

Figure 13-5. Method B.1 (Quick Term) for Shield Termination

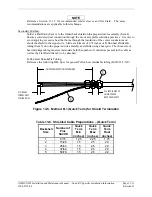

Table 13-6. Shielded Cable Preparations – (Quick Term)

Backshell

Size

Number of

Pins

Std/HD

Quick

Term

Min

(inches)

Quick

Term

Max

(inches)

Quick

Term

Float

(inches)

1 9/15

1.25

2.25

1.75

2 15/26

1.5

2.5

2.0

3 25/44

1.5

2.5

2.0

4 37/62

1.5

2.5

2.0

5 50/78

1.5

2.5

2.0