Page 13-10

G900X/G950 Installation and Maintenance Manual – Non LRU Specific Installation Information

Revision D

190-00719-00

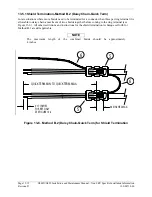

13.4.1 Shield Termination – Method B.1 (Quick Term)

If desired, the drain wire termination (Item 5) and the floating shield termination (Item 7) can be

effectively combined into a “Quick Term”. This method eliminates the float in the cable insulation and

moves the placement of the window which was described by the dimensions “Window Min” and

“Window Max” from Method A. This technique is depicted in Figure 13-7.

NOTE

The original purpose for separating the shield drain termination (Item 5) from the float

termination (Item 7) in Method A was to allow for a variety of lengths for the drain wires

so that the shield drain terminations (Item 5) would not all “bunch up” in the harness and

to eliminate loops in the drain wires. If Method B is chosen, as described in this section,

care must be taken to insure that all drain shield terminations can still be inspected. With

connectors which require a large number of shield terminations it may be best to use

Method A. This will allow the drain shield terminations (Item 5) a larger area to be

dispersed across.

Instructions for Method B (Quick Term)

Using this method, the instructions from Method A are followed except that:

1) Step 2 is eliminated

2) Steps 3 and 4 are replaced by the following:

At the end of the shielded cable (item 4), strip “Quick Term Min” to “Quick Term Max” (Table 4-1)

length of the jacket to expose the shield. Next trim the shield so that at most 0.35 inches remains

extending beyond the insulating jacket. Fold this remaining shield back over the jacket.

Connect a Flat Braid (Item 6) to the folded back shield of the prepared cable assembly. The flat braid

should go out the front of the termination towards the connector. It is not permitted to exit the rear of the

termination and loop back towards the connector. (See Figure 4-1). Make this connection using an

approved shield termination technique.

NOTE

FAA AC 43.13-1B Chapter 11, Section 8 (Wiring Installation Inspection Requirements)

may be a helpful reference for termination techniques.

Preferred Method:

Slide a solder sleeve (item 5) onto the prepared cable assembly (item 4) and connect the Flat

Braid (Item 6) to the shield using a heat gun approved for use with solder sleeves. It may prove

beneficial to use a solder sleeve with a pre-installed Flat Braid versus having to cut a length of

Flat Braid to be used. The chosen size of solder sleeve must accommodate both the number of

conductors present in the cable and the Flat Braid (item 6) to be attached.