G900X/G950 Installation and Maintenance Manual – Garmin GPS WAAS Antenna

Page 12-19

190-00719-00

Revision D

12.6.1 Preparation of Doubler

a.

Use Garmin P/N: 115-00846-00, or refer to Table 12-6 for guidance on selecting the appropriate

doubler drawing based on the thickness of skin at the antenna location. Make the doubler from

2024-T3 Aluminum (AMS-QQ-A-250/5), 0.063” sheet thickness.

b.

For installation in aircraft skins of thickness less than 0.051”, countersink the rivet holes in the

doubler for use with flush head rivets (MS20426AD4-x).

c.

When using Garmin P/N: 115-00846-00 doubler, sixteen rivet holes exist in the part. For

installation of Garmin P/N: 115-00846-10 in skins of thickness between 0.032” and 0.049”, only

those identified for use through the skin cutout detail and doubler installation (Figure 12-26) are

required.

12.6.2 Antenna Installation Instructions

a.

Refer to Table 12-6 for guidance on selecting the appropriate mounting cutout. Drill or punch the

holes to match the mating part (doubler).

b.

Install a doubler plate to reinforce the aircraft skin, as required. Refer to Section 12.5.9 for

doubler preparation and Table 12-6 for additional guidance on the doubler installation. Dimple

aircraft skin when the skin thickness is less than 0.051” for installation of flush head rivets.

Countersink aircraft skin when the skin thickness is between 0.051” and 0.063” for installation of

flush head rivets.

c.

Place install gasket, Garmin P/N: 253-00138-00, on top of aircraft skin using the four screw holes

to align the gasket.

d.

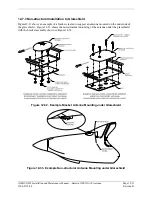

Locking nuts are required to secure the antenna (locking nutplates installed on doubler). Torque

the four supplied #10-32 stainless steel screws (Garmin P/N: 211-60212-20, MS51958-67, or

equivalent) 20-25 in-lbs. Torque should be applied evenly across all mounting studs to avoid

deformation of the mounting area.

e.

Ensure that the antenna base and aircraft skin are in continuous contact with the gasket.

f.

Seal the antenna and gasket to the fuselage using Dow Corning 738 Electrical Sealant or

equivalent. Run a bead of the sealant along the edge of the antenna where it meets the exterior

aircraft skin. Use caution to ensure that the antenna connectors are not contaminated with

sealant.

CAUTION

Do not use construction grade RTV sealant or sealants containing acetic acid. These

sealants may damage the electrical connections to the antenna. Use of these type sealants

may void the antenna warranty.