AIR CONDITIONING

1B-13

Thrust Bearing

Fig. 3 6 —In sta ll in g Rear T h r u s t Races and B e a rin g s

INTERNAL M EC H A N ISM

Gaging Operation

1. Install Compressing Fixture J-9397 on Holding

Fixture J-9396 iri vise. Place front cylinder half in

Compressing Fixture, flat side down. Front cylinder half has

long slot extending out from shaft hole.

2. Secure from Service parts stock

four

ZER O thrust

races and

three

Z ER O shoe discs.

3. Install a ZER O thrust race, thrust bearing, and a

second ZER O thrust race on front end of compressor shaft.

Lubricate races and bearing with petrolatum .

4. Insert threaded end of shaft through needle bearing

in front cylinder half, and allow thrust race and bearing

assembly to rest on hub of cylinder.

5. Now install a Z ER O thrust race on rear end of

com pressor shaft (Fig. 36), so that it rests on hub of axial

plate. Then install thrust bearing and a second ZER O thrust

race. Lubricate races and bearing with petrolatum .

6. Lubricate ball pockets of the No. 1 Piston with 525

viscosity refrigerant oil and place a ball in each socket. Use

balls previously removed if they are to be re-used.

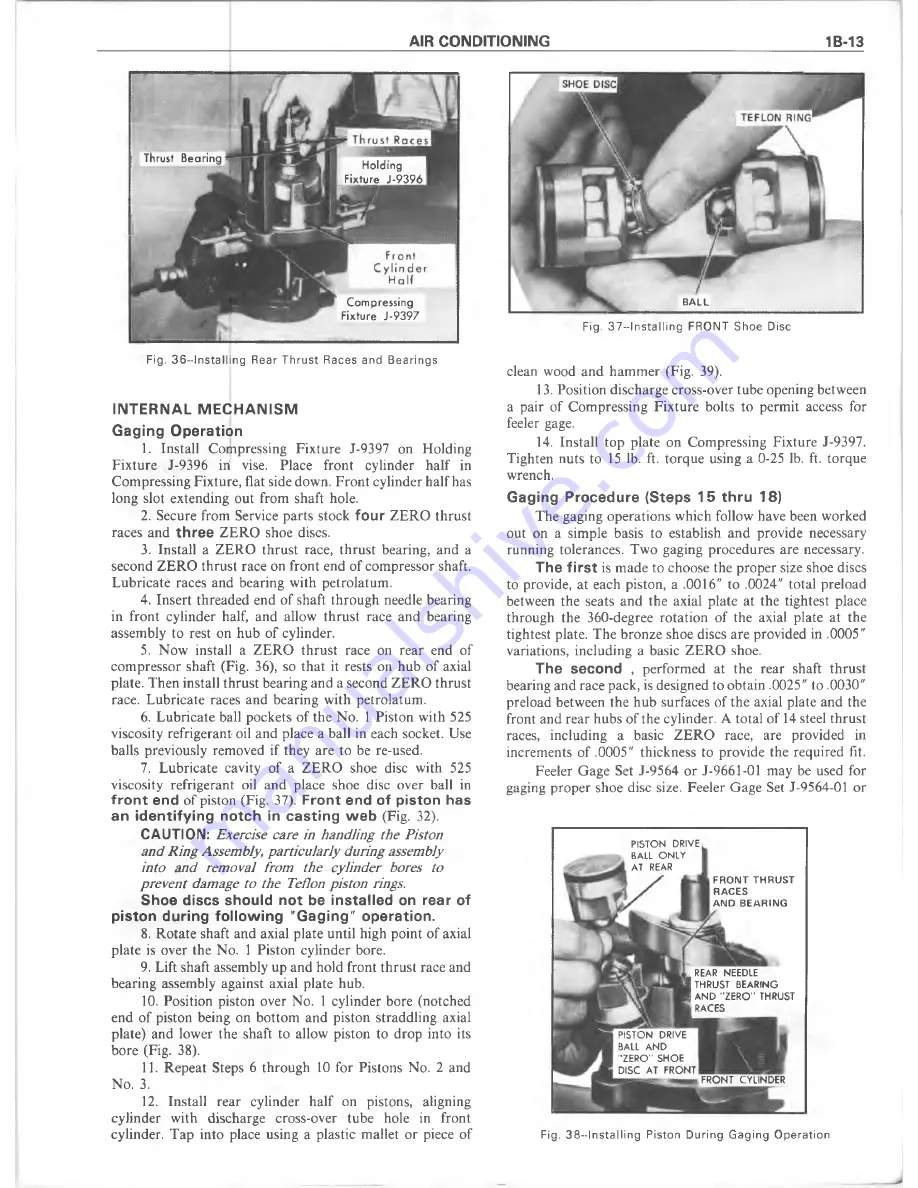

7. Lubricate cavity of a Z ER O shoe disc with 525

viscosity refrigerant oil and place shoe disc over ball in

front end

of piston (Fig. 37).

Front end of piston has

an identifying notch in casting web

(Fig. 32).

CAUTION:

Exercise care in handling the Piston

and Ring Assembly, particularly during assembly

into and removal from the cylinder bores to

prevent damage to the Teflon piston rings.

Shoe discs should not be installed on rear of

piston during following "Gaging" operation.

8. R otate shaft and axial plate until high point of axial

plate is over the No. 1 Piston cylinder bore.

9. Lift shaft assembly up and hold front thrust race and

bearing assembly against axial plate hub.

10. Position piston over No. 1 cylinder bore (notched

end of piston being on bottom and piston straddling axial

plate) and lower the shaft to allow piston to drop into its

bore (Fig. 38).

11. Repeat Steps 6 through 10 for Pistons No. 2 and

No. 3.

12. Install rear cylinder half on pistons, aligning

cylinder with discharge cross-over tube hole in front

cylinder. Tap into place using a plastic mallet or piece of

Holding

Fixture J-9

9396

Compressing

Fixture J-9397

B ALL

Fig. 3 7 —1 nsta lling FRONT Shoe Disc

clean wood and ham m er (Fig. 39).

13. Position discharge cross-over tube opening between

a pair of Compressing Fixture bolts to permit access for

feeler gage.

14. Install top plate on Compressing Fixture J-9397.

Tighten nuts to 15 lb. ft. torque using a 0-25 lb. ft. torque

wrench.

Gaging Procedure (Steps 15 thru 18)

The gaging operations which follow have been worked

out on a simple basis to establish and provide necessary

running tolerances. Two gaging procedures are necessary.

The first

is m ade to choose the proper size shoe discs

to provide, at each piston, a .0016" to .0024" total preload

between the seats and the axial plate at the tightest place

through the 360-degree rotation of the axial plate at the

tightest plate. The bronze shoe discs are provided in .0005"

variations, including a basic ZER O shoe.

The second

, performed at the rear shaft thrust

bearing and race pack, is designed to obtain .0025" to .0030"

preload between the hub surfaces of the axial plate and the

front and rear hubs of the cylinder. A total of 14 steel thrust

races, including a basic Z E R O race, are provided in

increments of .0005" thickness to provide the required fit.

Feeler Gage Set J-9564 or J-9661-01 may be used for

gaging proper shoe disc size. Feeler Gage Set J-9564-01 or

PISTON DRIVE

BALL ONLY

AT REAR

F R O N T T H R U S T

R A C E S

A N D B E A R IN G

REAR NEEDLE

THRUST BEARING

AND "ZERO" THRUST

RACES

PISTON DRIVE

BALL AND

'ZERO” SHOE

DISC AT FRONT

FRONT CYLINDER

Fig. 3 8 —1 nsta llin g Piston D u rin g G a g in g O p e ra tio n

Содержание 1977 10 Series

Страница 1: ......

Страница 2: ......

Страница 4: ......

Страница 6: ......

Страница 42: ......

Страница 65: ...STEERING 3B 23 Fig 3B 65 M easure Back and Remark Housing Fig 3B 67 Tighten Lock Nut...

Страница 86: ...4B 14 OVERHAUL MANUAL Fig 4B 28 Gear Teeth C ontact Pattern Check...

Страница 125: ...REAR AXLE DIFFERENTIAL 4B 53 Fig 18E Gear Teeth Contact Pattern Check...

Страница 156: ......

Страница 164: ...4C 8 OVERHAUL MANUAL Fig 4C 12 Gear Tooth Pattern Contact Pattern...

Страница 166: ......

Страница 194: ......

Страница 284: ......

Страница 320: ......

Страница 322: ...400 7A 2 OVERHAUL MANUAL Fig 7A 1C Side Cross Section Typical...

Страница 444: ...7B 64 OVERHAUL MANUAL Fig 7B 11S M od el 2 03 Transfer Case Exploded V iew...

Страница 458: ......

Страница 466: ......

Страница 467: ......

Страница 468: ......