4C-6

OVERHAUL MANUAL

Fig. 4 C -9 —In s ta llin g In n e r P in io n C ore and R o lle r

6. Install drive pinion and inner bearing cone and roller

assembly in differential carrier.

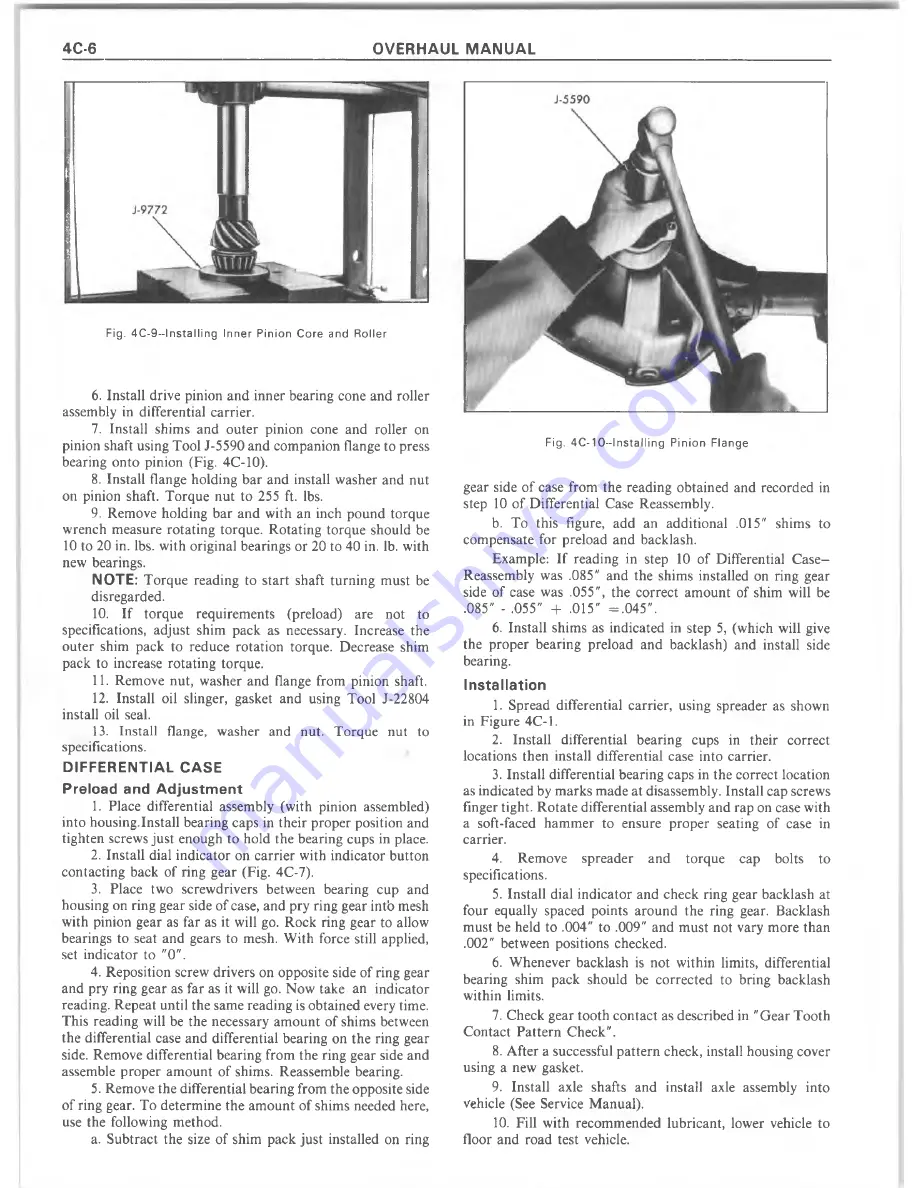

7. Install shims and outer pinion cone and roller on

pinion shaft using Tool J-5590 and companion flange to press

bearing onto pinion (Fig. 4C-10).

8. Install flange holding bar and install washer and nut

on pinion shaft. Torque nut to 255 ft. lbs.

9. Remove holding bar and with an inch pound torque

wrench measure rotating torque. Rotating torque should be

10 to 20 in. lbs. with original bearings or 20 to 40 in. lb. with

new bearings.

NOTE:

Torque reading to start shaft turning must be

disregarded.

10. If torque requirem ents (preload) are not to

specifications, adjust shim pack as necessary. Increase the

outer shim pack to reduce rotation torque. Decrease shim

pack to increase rotating torque.

11. Remove nut, washer and flange from pinion shaft.

12. Install oil slinger, gasket and using Tool J-22804

install oil seal.

13. Install flange, washer and nut. Torque nut to

specifications.

DIFFERENTIAL CASE

Preload and Adjustm ent

1. Place differential assembly (with pinion assembled)

into housing.Install bearing caps in their proper position and

tighten screws just enough to hold the bearing cups in place.

2. Install dial indicator on carrier with indicator button

contacting back of ring gear (Fig. 4C-7).

3. Place two screwdrivers between bearing cup and

housing on ring gear side of case, and pry ring gear intb mesh

with pinion gear as far as it will go. Rock ring gear to allow

bearings to seat and gears to mesh. W ith force still applied,

set indicator to "0".

4. Reposition screw drivers on opposite side of ring gear

and pry ring gear as far as it will go. Now take an indicator

reading. Repeat until the same reading is obtained every time.

This reading will be the necessary am ount of shims between

the differential case and differential bearing on the ring gear

side. Remove differential bearing from the ring gear side and

assemble proper am ount of shims. Reassemble bearing.

5. Remove the differential bearing from the opposite side

of ring gear. To determ ine the am ount of shims needed here,

use the following method.

a. Subtract the size of shim pack just installed on ring

Fig. 4 C - 10—1 n s ta llin g P in io n Flange

gear side of case from the reading obtained and recorded in

step 10 of Differential Case Reassembly.

b.

To this figure, add an additional .015" shims to

compensate for preload and backlash.

Example: If reading in step 10 of Differential C a se -

Reassembly was .085" and the shims installed on ring gear

side of case was .055", the correct am ount of shim will be

.085" - .055" + .015" = .0 4 5 ".

6.

Install shims as indicated in step 5, (which will give

the proper bearing preload and backlash) and install side

bearing.

Installation

1. Spread differential carrier, using spreader as shown

in Figure 4C-1.

2. Install differential bearing cups in their correct

locations then install differential case into carrier.

3. Install differential bearing caps in the correct location

as indicated by m arks made at disassembly. Install cap screws

finger tight. R otate differential assembly and rap on case with

a soft-faced ham m er to ensure proper seating of case in

carrier.

4.

Remove spreader and

torque cap bolts to

specifications.

5. Install dial indicator and check ring gear backlash at

four equally spaced points around the ring gear. Backlash

must be held to .004" to .009" and m ust not vary more than

.002" between positions checked.

6. W henever backlash is not within limits, differential

bearing shim pack should be corrected to bring backlash

within limits.

7. Check gear tooth contact as described in "G ear Tooth

Contact P attern Check".

8. After a successful pattern check, install housing cover

using a new gasket.

9. Install axle shafts and install axle assembly into

vehicle (See Service M anual).

10. Fill with recom m ended lubricant, lower vehicle to

floor and road test vehicle.

Содержание 1977 10 Series

Страница 1: ......

Страница 2: ......

Страница 4: ......

Страница 6: ......

Страница 42: ......

Страница 65: ...STEERING 3B 23 Fig 3B 65 M easure Back and Remark Housing Fig 3B 67 Tighten Lock Nut...

Страница 86: ...4B 14 OVERHAUL MANUAL Fig 4B 28 Gear Teeth C ontact Pattern Check...

Страница 125: ...REAR AXLE DIFFERENTIAL 4B 53 Fig 18E Gear Teeth Contact Pattern Check...

Страница 156: ......

Страница 164: ...4C 8 OVERHAUL MANUAL Fig 4C 12 Gear Tooth Pattern Contact Pattern...

Страница 166: ......

Страница 194: ......

Страница 284: ......

Страница 320: ......

Страница 322: ...400 7A 2 OVERHAUL MANUAL Fig 7A 1C Side Cross Section Typical...

Страница 444: ...7B 64 OVERHAUL MANUAL Fig 7B 11S M od el 2 03 Transfer Case Exploded V iew...

Страница 458: ......

Страница 466: ......

Страница 467: ......

Страница 468: ......