EUROBLOC

SERVICE MANUAL FOR HOIST

196/212

This document and the information contained herein, is the exclusive property of Verlinde S.A.S. and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of Verlinde S.A.S.

Copyright © (2013) Verlinde S.A.S. All rights reserved.

06/2015

3

4

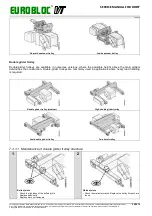

Install the power supply plug (8) to the motor.

Install the machinery covers and switch ON the power supply

to the hoist.

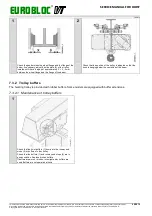

7.3.5.6 Maintenance of traveling brake, DC brake for motors MF07 and MF10

1

2

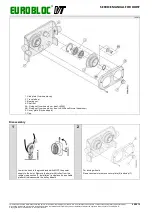

Disassemble the brake and clean the brake disc (5) and the

friction disc (6).

Check the brake type on the rating plate that is fixed to the

brake. Measure the thickness of the brake disc (5).

Replace the brake disc if the thickness (t) is less than the

minimum thickness as according to the table below.

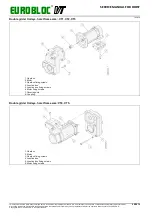

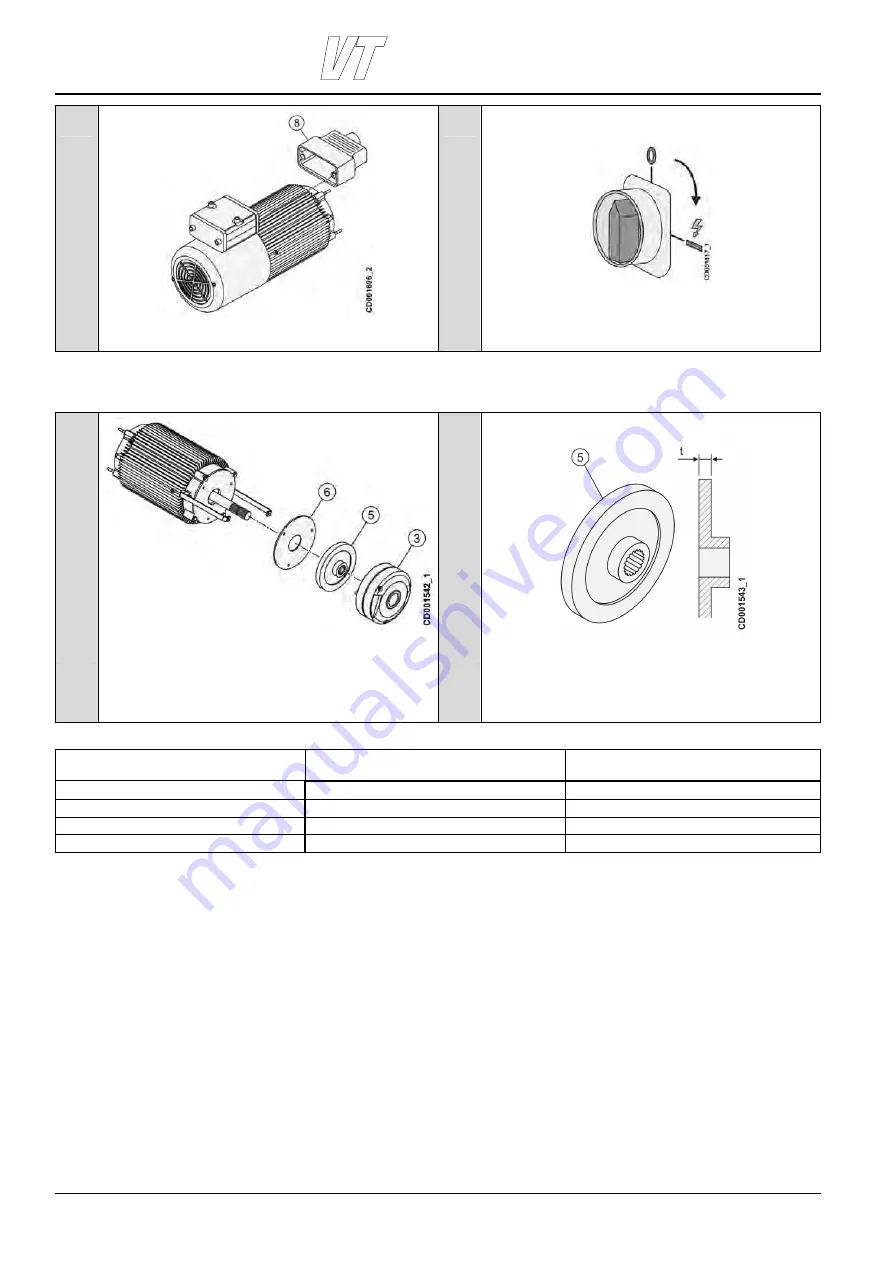

Brake type and size

Min. thickness of brake disc

Tightening torque for

brake fixing screws

NM38770NR#, 16 Nm

6.8 mm

5 Nm / 3.7 lbf.ft

NM38771NR#, 8 Nm

6.6 mm

5 Nm / 3.7 lbf.ft

NM38720NR#, 21 Nm

7.6 mm

9 Nm / 6. lbf.ft

NM38721NR#, 14 Nm

7.6 mm

9 Nm / 6. lbf.ft