EUROBLOC

SERVICE MANUAL FOR HOIST

72/212

This document and the information contained herein, is the exclusive property of Verlinde S.A.S. and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of Verlinde S.A.S.

Copyright © (2013) Verlinde S.A.S. All rights reserved.

06/2015

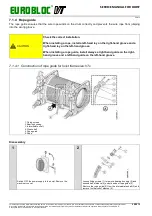

Adjustment

1

2

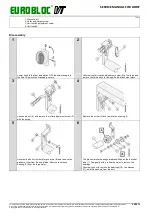

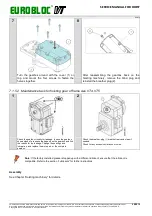

Rope guide initial adjustment

Tighten the two self-locking nuts (6) evenly until the rope

guide is snug against the rope drum and the rod ends go

through the frames in a straight line. If either nut is tightened

more than the other, the rod gets bent or misaligned.

Adjust the nuts so that the guide does not rotate around the

drum by gravity alone, but it rotates if extra force of

20 N…30 N is applied in the up or down direction.

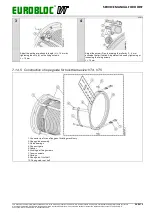

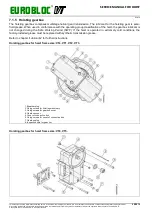

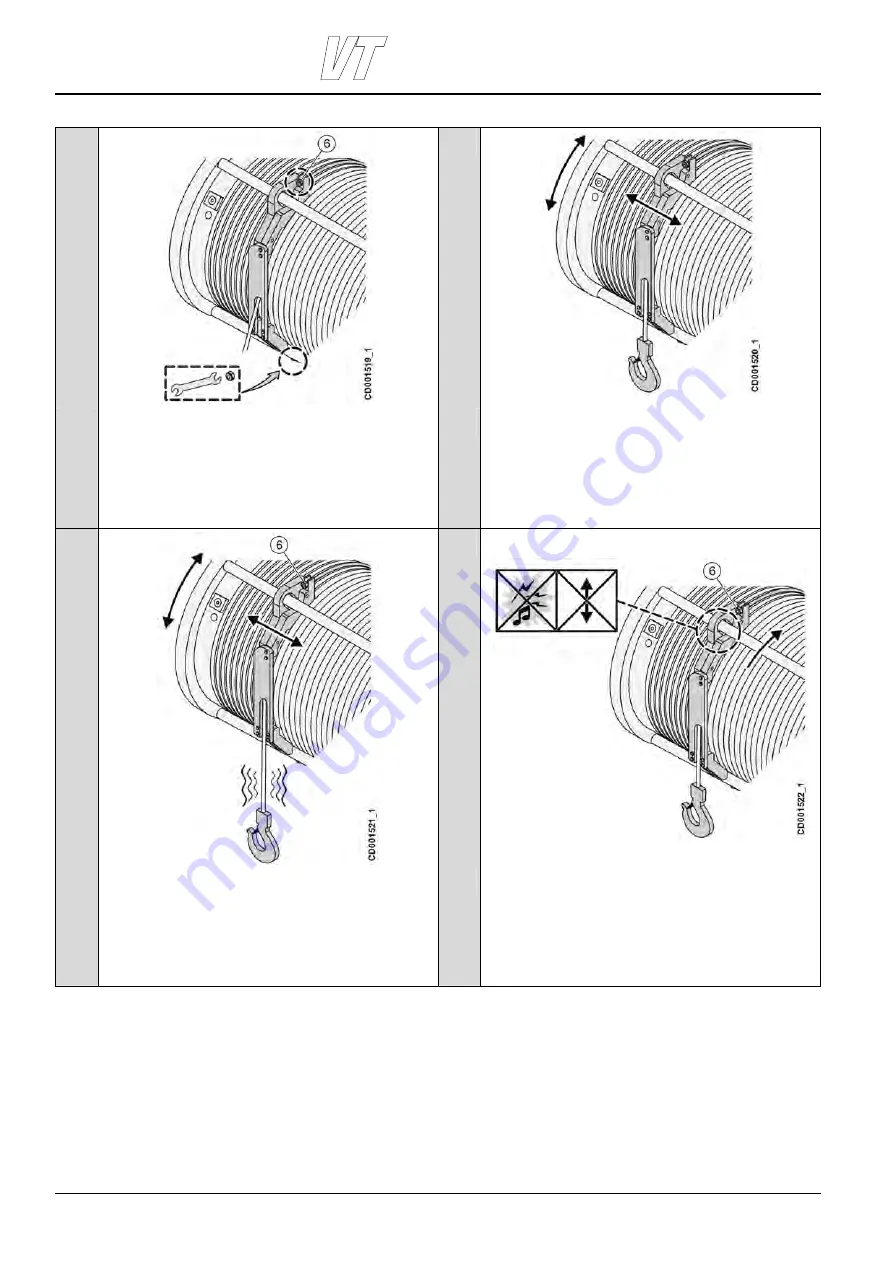

Rope guide test drive and final adjustment

Test drive the hoist in both up and down direction and check

that the rope guide travels through the whole height of lift

without evidence of strong vibrations or excessive wear on the

drum.

3

4

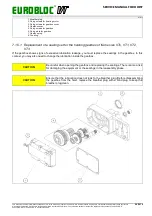

Rope guide too tight:

If the rope guides vibrate strongly, it is likely that they are too

tight against the drum. Loosen the upper self-locking nut (6)

by a quarter turn and retry. If the guides are still too tight,

loosen the lower self-locking nut (6) by a quarter turn and

retry. Continue loosening the nuts in turns until the vibrations

disappear.

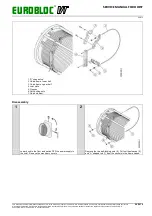

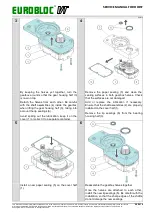

Rope guide too loose:

If the rope guides become too loose against the drum, they

will begin to rotate around the drum by gravity causing in an

audible clanking noise each time the hoist stops after upward

motion. This is a result of gravity pulling the loose guides

against the intermediate shaft. If the clanking noise occurs,

tighten the self-locking nuts (6) in turns until the guides no

longer rotate around the drum by gravity.