EUROBLOC

SERVICE MANUAL FOR HOIST

68/212

This document and the information contained herein, is the exclusive property of Verlinde S.A.S. and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of Verlinde S.A.S.

Copyright © (2013) Verlinde S.A.S. All rights reserved.

06/2015

5

6

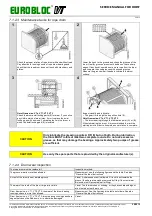

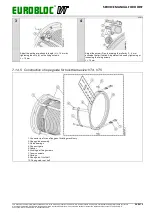

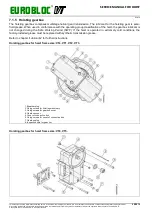

Reinstall the dismounted intermediate shaft (1) and install the

guide bearings (3) on the rope guide.

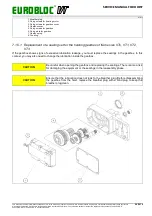

Switch ON the power supply to the hoist.

7

8

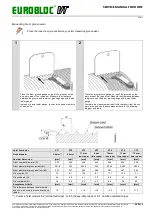

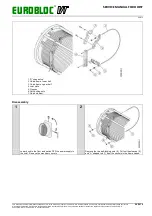

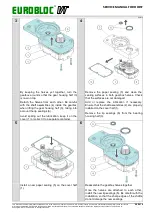

Test drive the hoist while observing the rope guide travel

through the whole height of lift. Test the tightness of the rope

guide at both the upper and lower hoisting limit to make sure

that there is no binding at either end. Adjust if necessary.

Install the machinery covers.

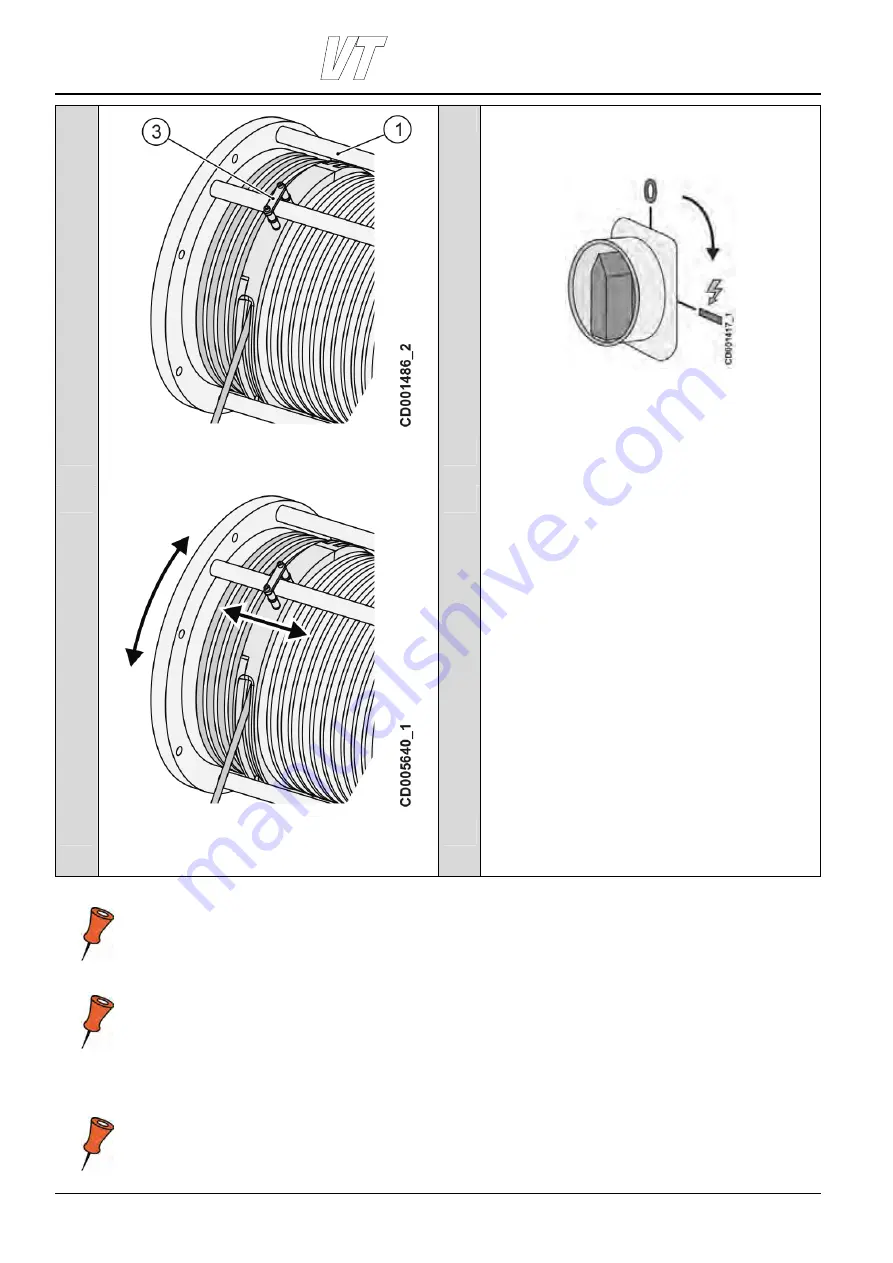

Note: Friction between the rope guide and drum causes wear on the drum and the guide.

Note: The rope guide should be allowed to move axially 1…3 mm. In this way, it is loose enough not to bind on

the drum and tight enough not to rise up or jump to a wrong drum groove.

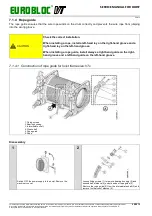

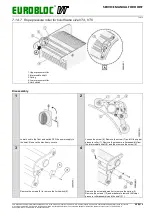

7.1.4.6 Construction of rope guide for hoist frame size: VT4, VT5 (On models before 12.2006)

Note: It is recommended to change the rope guide into a newer model.