EUROBLOC

SERVICE MANUAL FOR HOIST

212/212

This document and the information contained herein, is the exclusive property of Verlinde S.A.S. and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of Verlinde S.A.S.

Copyright © (2013) Verlinde S.A.S. All rights reserved.

06/2015

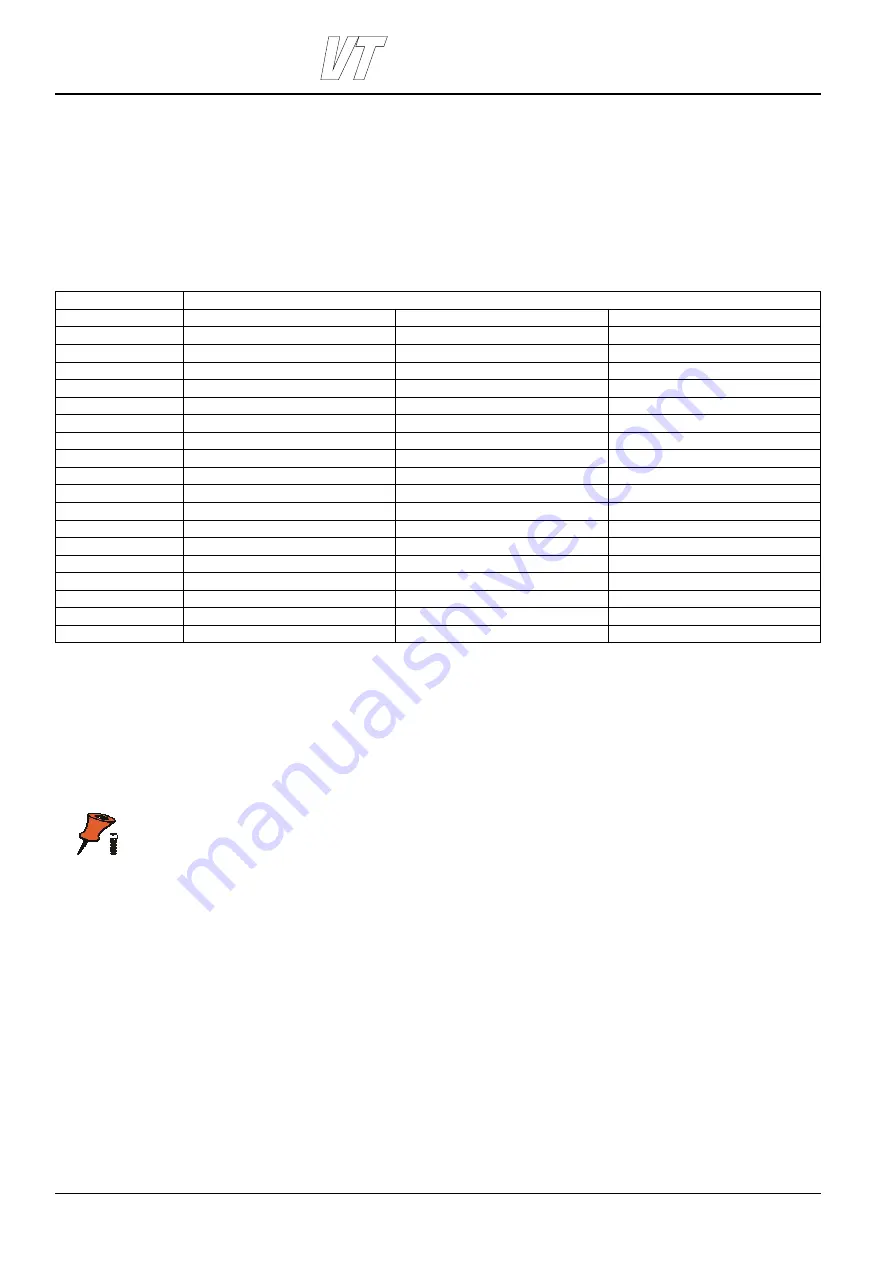

9 APPENDIX: TIGHTENING TORQUES

The following tightening torques shall be applied on bolts in cases, where tightening of a bolt is not specified in any

way in the relevant drawing.

Tightening must be done using a tool or method, where the applied torque is measured and indicated.

See below screw joints, recommended tightening torques. Measurements are given in Nm. A friction coefficient

µ

=

0,14 is assumed in the calculations of the preceding tightening torques.

Tightening torque (Nm)

Size

Strength class 8.8

Strength class 10.9

Strength 12.9

M2

Hand tight (0.39)

Hand tight (0.55)

Hand tight (0.66)

M3

Hand tight (1.41)

Hand tight (1.98)

Hand tight (2.37)

M4

Hand tight (3.3)

Hand tight (4.8)

Hand tight (5.6)

M5

Hand tight (6.5)

Hand tight (9.5)

Hand tight (11.2)

M6

Hand tight (11.3)

Hand tight (16.5)

Hand tight (19.3)

M8

25

35

42

M10

49

69

83

M12

86

122

145

M14

136

190

230

M16

210

300

360

M18

290

410

495

M20

410

590

710

M22

560

790

950

M24

710

1000

1200

M27

1040

1460

1750

M30

1410

2000

2400

M33

1910

2700

3250

M36

2460

3500

4200

These torques are for

screws DIN912, DIN931, DIN933

nuts DIN934, DIN935, DIN982, DIN985, DIN98

Others shall be specified in drawings

Note: It is recommended that self-locking nuts (Nyloc nut) are always replaced when removed. Self locking nuts

can be reused no more than 5 times.