EUROBLOC

SERVICE MANUAL FOR HOIST

30/212

This document and the information contained herein, is the exclusive property of Verlinde S.A.S. and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of Verlinde S.A.S.

Copyright © (2013) Verlinde S.A.S. All rights reserved.

06/2015

Component

In

te

rv

a

l

Inspection and maintenance task

Interval is SWP% reduction or calendar months

See further instructions

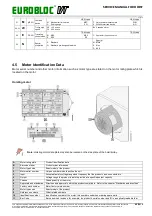

Traveling motor

10%

12

Inspect for any unusual noise or vibration.

Verify that the cooling fan is working properly.

Clean the cooling ribs surface from dust and dirt.

Check that all motor fastenings are tight and the motor is properly on

its position.

If the bolts are loose, tighten them to the proper torque.

Traveling motor

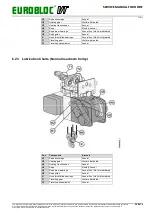

Hoisting brake

10%

12

Check that there is no visible damage.

Check that the outside surface of the brake is clean.

Drive with nominal load and test that lifting and lowering brake smoothly

and the braking time and distance is acceptable.

Disassemble the hoisting brake:

• Measure disk pad thickness

• Inspect the center hub teeth for cracks or any wear. Replace it if worn

• Replace the disk when its condition is not complying with specifications

• Clean the inner side of the brake from dust and dirt.

•

When the maximum allowed number of braking actions has taken

place (CID Warning: Br SWP %), replace the hoisting brake and the

hoisting coupling. Check also the condition of coupling splines in

the motor shaft and in the gear shaft.

Hoisting brake

Replacement of a hoisting brake

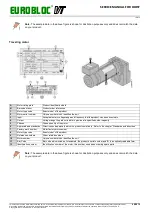

Traveling brake

10%

12

20%

24

Inspect that there is no visible damage.

Check that the outside surface of the brake is clean.

Drive with load and test that brake operates smoothly and the braking time

and distance is acceptable.

Disassemble the traveling brake:

• Measure the air gap, clean, and adjust the brake if needed

• Measure the brake pad. Replace it if necessary.

Construction of compact brake for

traveling motor MF06

Construction of DC brake for motor

MF06LB* or MF06 two-speed

Construction of DC brake for motors

MF07 and MF10

Maintenance of traveling brake,

compact brake

Maintenance of traveling brake, DC

brake for motor MF06

Maintenance of traveling brake, DC

brake for motors MF07 and MF10

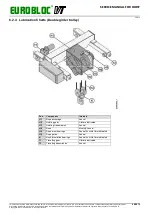

Hoisting gear

10%

12

Check that the gearbox fastenings are secure.

Inspect the gearbox for possible lubrication leakage. If there is an

excessive leakage, open the gearbox and replace the sealings.

Test the gear running sound and vibrations with load.

Check that the breather-plug is free of dust and dirt.

Check the temperature of the hoisting gearbox by hand.

Check the oil level if an oil-filled hoisting gear.

Hoisting gearbox

Lubrication

Traveling gear

10%

12

Check that the gearbox fastenings are secure.

Inspect the gearbox for possible lubrication leakage.

Check visually the torque support mounting and the rubber bushing

if present.

Test the gear running sound and vibrations with load.

Check that the breather-plug is free of dust and dirt.

Check the temperature of the traveling gearbox by hand.

Check the oil level if an oil-filled traveling gear.

Open transmission:

• Inspect the open transmission visually for wear

• Lubricate the open transmission.

Traveling machinery

Maintenance of traveling machinery

unit

Lubrication