EUROBLOC

SERVICE MANUAL FOR HOIST

19/212

This document and the information contained herein, is the exclusive property of Verlinde S.A.S. and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of Verlinde S.A.S.

Copyright © (2013) Verlinde S.A.S. All rights reserved.

06/2015

5 GENERAL ABOUT MAINTENANCE

Maintenance actions, excluding the daily actions performed by operators, must be done by service personnel who

are authorized by the product manufacturer.

WARNING

Do not modify the product without the manufacturer’s permission. Any

modifications to the product structures or performance values must only be

made after they have been approved by the product’s manufacturer.

WARNING

Do not allow the product to be used if it is not in proper condition. The usage

of a defective product can result in serious damage, injury or death.

CAUTION

Only use genuine spare parts, materials and lubricants approved by the

product’s manufacturer.

CAUTION

Never wash the crane or hoist with chemical products or high pressure water

jets, as they can cause problems like detaching of the stickers and water

entering inside the electrical components.

For installation and commissioning instructions, refer to the separate manual: “Installation and Commissioning

for Hoist”.

5.1

Service process

Service process should include following steps.

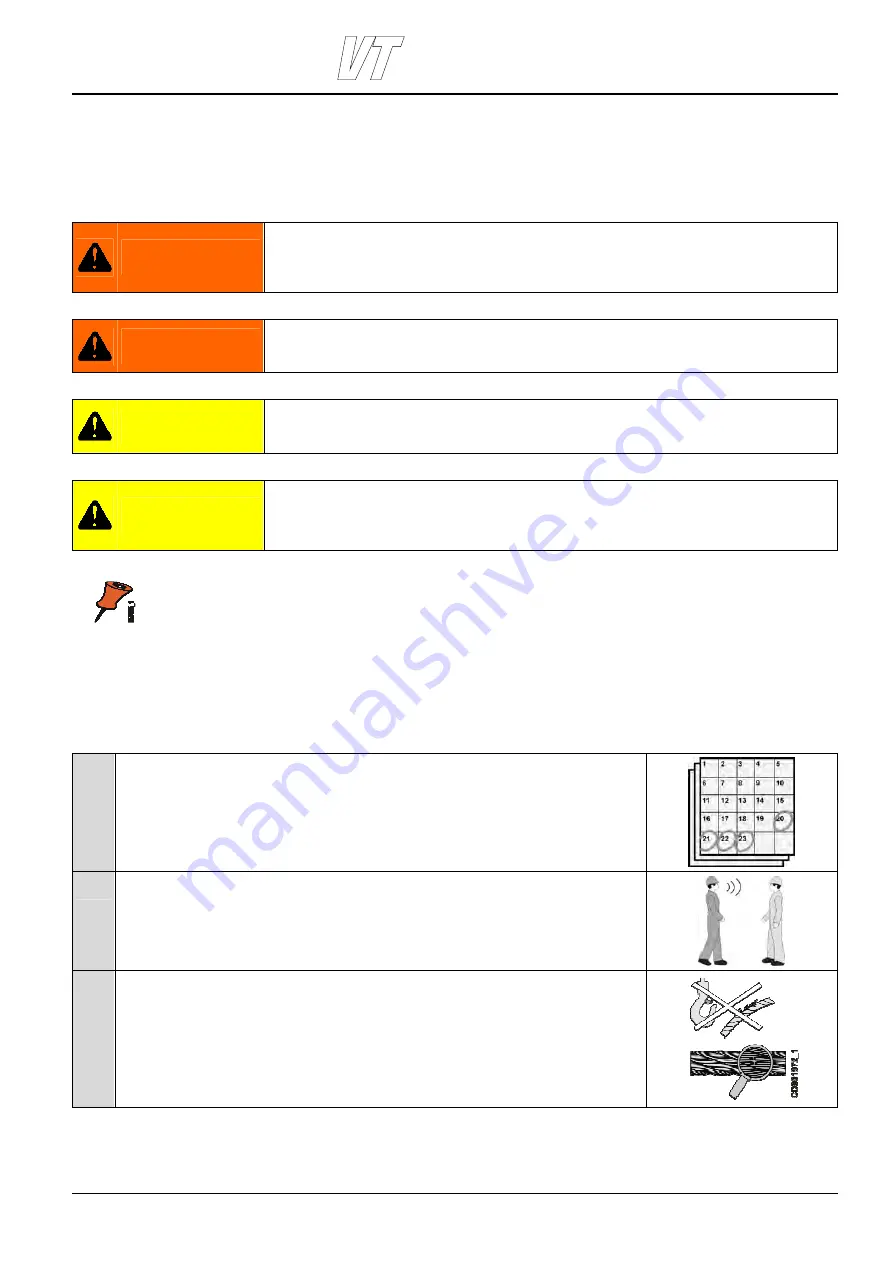

1

Preliminary actions

This may include:

• Prepare schedules, process plans and documentation.

• Reserve sufficient resourses like properly trained personnel, enough time and apporiate tools.

• Plan safety actions and reserve proper safety equipment.

2

Examination of usage and service history

This may include document reviews and discussions with Owner and Operator:

• Check Log book for service actions and plans enlisted.

• Observe the intended use and cahanges of usage with Owner and Operator.

• Collect Owner’s and Operator’s experiences and observations like unusual or irregular

operation of the equipment.

3

Inspection

Carry out independent inspection to assess the condition of the product. Note down all

irregularities not present in previous records. Carry out all inspections including daily inspection

and periodic inspections according to maintenance program.