EUROBLOC

SERVICE MANUAL FOR HOIST

116/212

This document and the information contained herein, is the exclusive property of Verlinde S.A.S. and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of Verlinde S.A.S.

Copyright © (2013) Verlinde S.A.S. All rights reserved.

06/2015

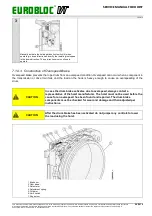

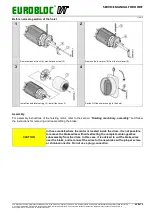

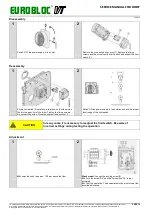

Note: Overspeed activates the drum brake if equipped with an overspeed brakeVT3. If overspeed drum brake

is activated, further lowering is rejected.

WARNING

Ensure that the brake temperature does not increase in an uncontrolled

manner.

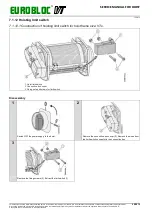

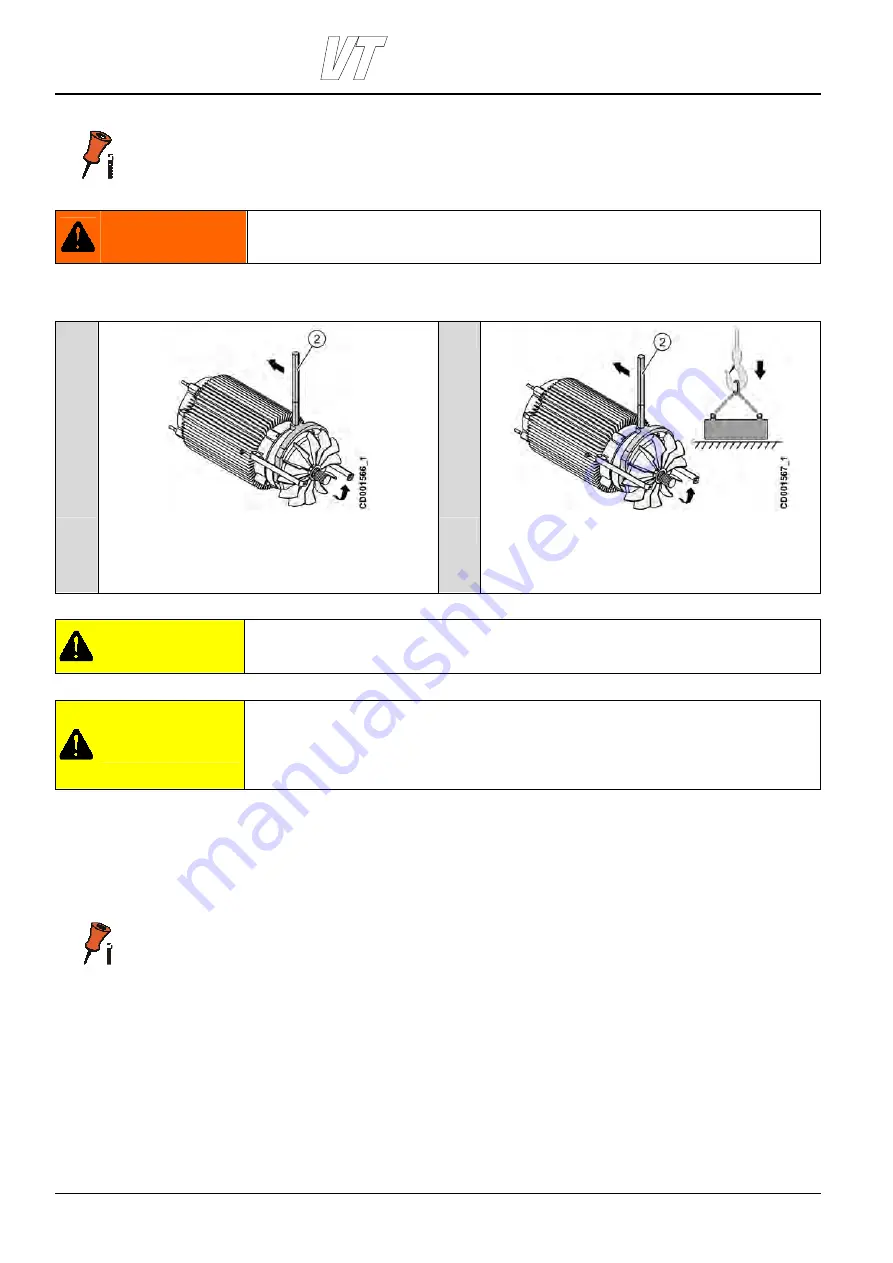

Lowering the load

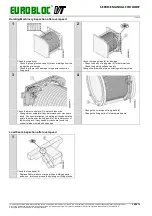

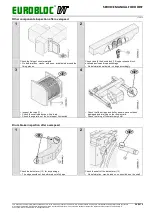

1

2

Pull the lever arm (2) carefully to open the brake and release

immediately when motor starts to rotate.

Pull and release a few times to study how the rotational speed

is growing.

Once known how the rotational speed behaves, open the

brake shortly and close again before the rotational speed

reaches the maximum using the lever arm (2).

Repeat the procedure until the load is lowered safely to the

floor.

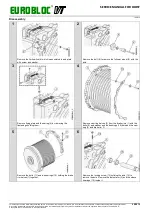

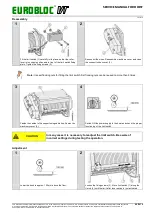

CAUTION

Let the brake cool down for at least one minute after five times manually

opening the brake.

CAUTION

When the brake temperature exceeds 100

°°°°

C (water drop boils), let it cool down

for a longer period at higher intervals (for example, after 4 times opening the

brake). Overheating the brake damages the friction material and the load may

drop.

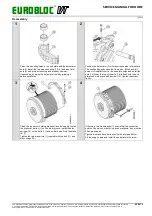

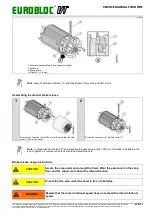

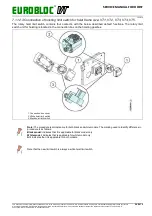

7.1.11 Manual crank

Manual brake release and manual crank is used to move the load in case of power failure.

Note: In hoist models that are equipped with two hoisting motors (and thus with two main brakes), both brakes

must be manually opened with levers simultaneously and both motors must be equipped with a crank. This

requires two persons to carry out the action.