EUROBLOC

SERVICE MANUAL FOR HOIST

55/212

This document and the information contained herein, is the exclusive property of Verlinde S.A.S. and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of Verlinde S.A.S.

Copyright © (2013) Verlinde S.A.S. All rights reserved.

06/2015

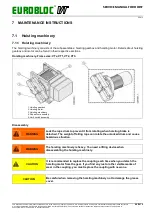

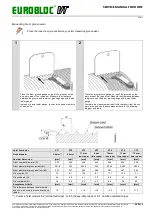

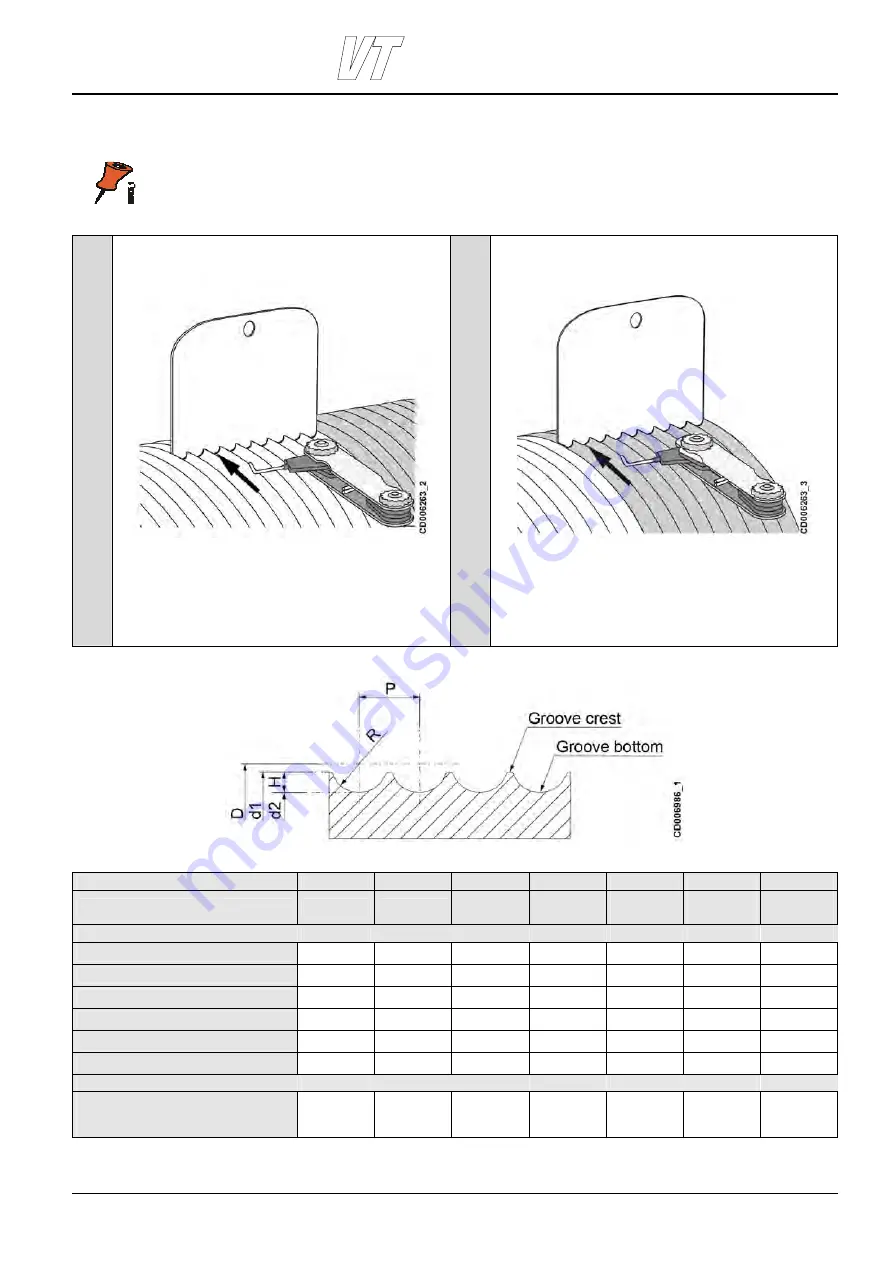

Measuring drum groove wear

Clean the rope drum grooves before you start measuring groove wear.

1

2

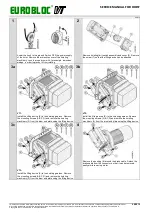

Place the drum groove gauge on top of the grooves on the

non-worn area of the rope drum. Measure the clearance

between the groove and the drum groove gauge with a wire

feeler gauge.

Instead of a wire feeler gauge, you can also use a steel wire

of same size.

Place the drum groove gauge on top of the grooves on the

worn area of the rope drum. Measure the clearance between

the groove and the drum groove gauge with a wire feeler

gauge.

Compare the measurement result with the result from the non-

worn area, and see the acceptance criteria in the following

diagram and table.

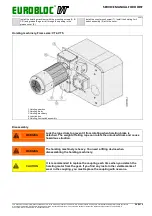

Hoist frame size

VT1

VT2

VT3

VT3

VT4

VT4

VT5

Rope diameter

6.4 mm**

8.0 mm

11 mm

(one rope)

8 mm

(two ropes)

15 mm

(one rope)

11 mm

(two ropes)

15 mm

(two ropes)

Nominal dimension

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

Drum nominal diameter (D)

303

355

406

406

608

608

608

Drum diameter at groove crest (d1)

301.8

353

403.2

404

604.2

605.2

604.2

Drum diameter at groove bottom (d2)

297

347

395

398

593

597

593

Groove pitch (P)

7.2

9.1

12.5

9.1

17.1

12.5

17.1

Groove depth (H)

2.4

3.0

4.1

3.0

5.6

4.1

5.6

Groove radius (R)

3.4

4.2

5.8

4.2

8.0

5.8

8.0

Acceptance criteria

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

The difference between the worn area

and non-worn area in groove depth and

radius:

1.0

1.0

<1.0

<1.0

<1.5

<1.0

<1.5

**) In some hoist models 6.2 (old default rope) or 6.5 (heavy-duty rope) or 6.7 (rotation resistant rope).