EUROBLOC

SERVICE MANUAL FOR HOIST

54/212

This document and the information contained herein, is the exclusive property of Verlinde S.A.S. and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of Verlinde S.A.S.

Copyright © (2013) Verlinde S.A.S. All rights reserved.

06/2015

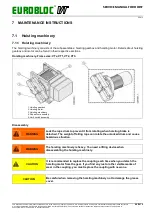

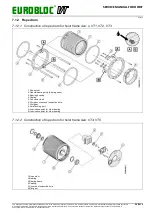

7.1.2.3 Maintenance tasks for rope drum

1

2

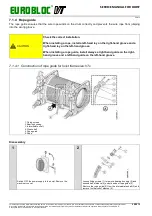

Check the proper rotation of rope drum with and without load.

Pay attention to running sound of rope drum bearings and

check that the rope drum does not touch with machinery end

plates.

Lower the hook to the ground and check the grooves of the

drum. Healthy grooves are smooth and do not have sharp

edges. If any doubt, unwind some more rope from the drum

and compare the used grooves with unused grooves.

Measure the groove wear if needed. Lubricate the drum

surface.

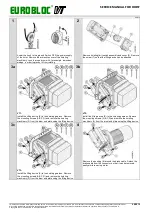

3

4

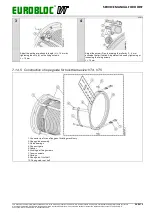

Hoist frame size: VTs, VT1, VT2, VT3

Check the drum axial locking parts (8) for wear. If you notice

any visible marks of wear (max. 2 mm), replace the axial

locking part with new one. Lubricate groove in the drum, in

which the axial locking part (8) is located.

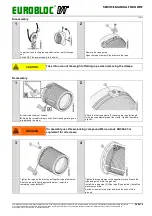

Inspect visually and lubricate:

• The gear rim through the inspection hole (6).

Hoist frame size: VTs, VT1, VT2, VT3

• The drum bearing through the lubrication point (A) or (B)

When lubricating the drum, it is recommended to mark the

starting point in order to know when one rotation is complete.

CAUTION

Only lubricate the greasing points A OR B, but not both. During lubrication,

the drum MUST rotate at least two complete rounds. Do not use excessive

grease, as that may damage the bearings. Approximately two pumps of grease

are sufficient.

CAUTION

Use only the spare parts that are provided by the original manufacturer(s).

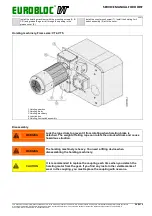

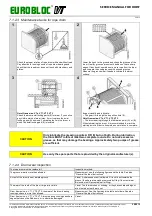

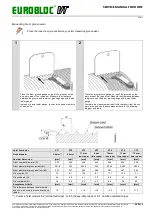

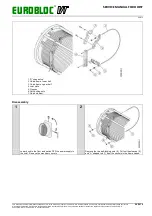

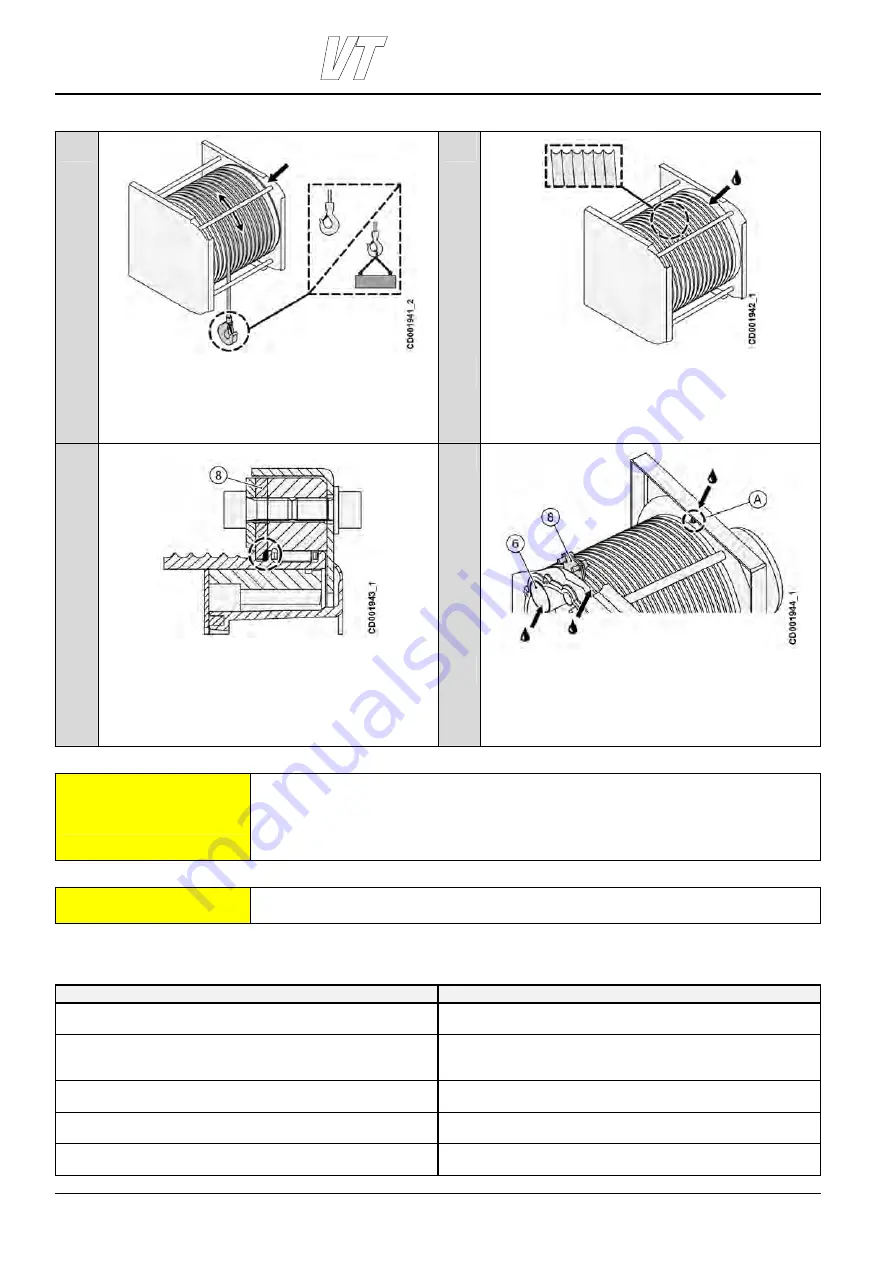

7.1.2.4 Drum wear inspection

The rope drum must be replaced if:

Inspection method:

The groove wear is more than allowed.

Measurement, see the following figures and the table. See also

“General Overhaul Instructions”.

A crest of the drum is bent towards groove.

Visual. A sharpened crest is allowed if it is not bent towards the

groove (the sharp area can be removed by filing if the crest wear

dimension is still acceptable after filing).

The wear of the teeth of the drum rim gear is visible.

Visual. Teeth are broken or missing, or they have sharp endings or

are otherwise clearly worn out.

Drum frame size: s, VT1, VT2, VT3: the wear of the drum bearing

running surface is more than allowed.

Measurement. See the figure and the table as follows. See also

“General Overhaul Instructions”.

Drum frame size: s, VT1, VT2, VT3: drum bearing housing has sharp

edges that cannot be filed down, or is otherwise damaged.

Visual.