EUROBLOC

SERVICE MANUAL FOR HOIST

22/212

This document and the information contained herein, is the exclusive property of Verlinde S.A.S. and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of Verlinde S.A.S.

Copyright © (2013) Verlinde S.A.S. All rights reserved.

06/2015

5.3

Approaching Theoretical Calculated Lifetime

In order to ensure safe operation of cranes, the proper working and operational condition shall be maintained

according to standard ISO 9927.

This requirement covers also special assessments to be carried out by an expert engineer at regular intervals to

check the remaining Safe Working Period (SWP) of the hoist as stated in standard ISO 12482-1.

The condition monitoring unit (CID) (if fitted) provides two different SWP values: the runtime-based SWP (CID

parameter 2-12 SWPRT% ), and the working cycle-based SWP (CID parameter 2-15: SWPHC%). The CID display

of the data counter SWP always shows the lesser value of two parameters.

If the component does not have a condition monitoring unit, use the method explained in the APPENDIX: SAFE

WORKING PERIOD (SWP) CALCULATION to calculate the remaining SWP%.

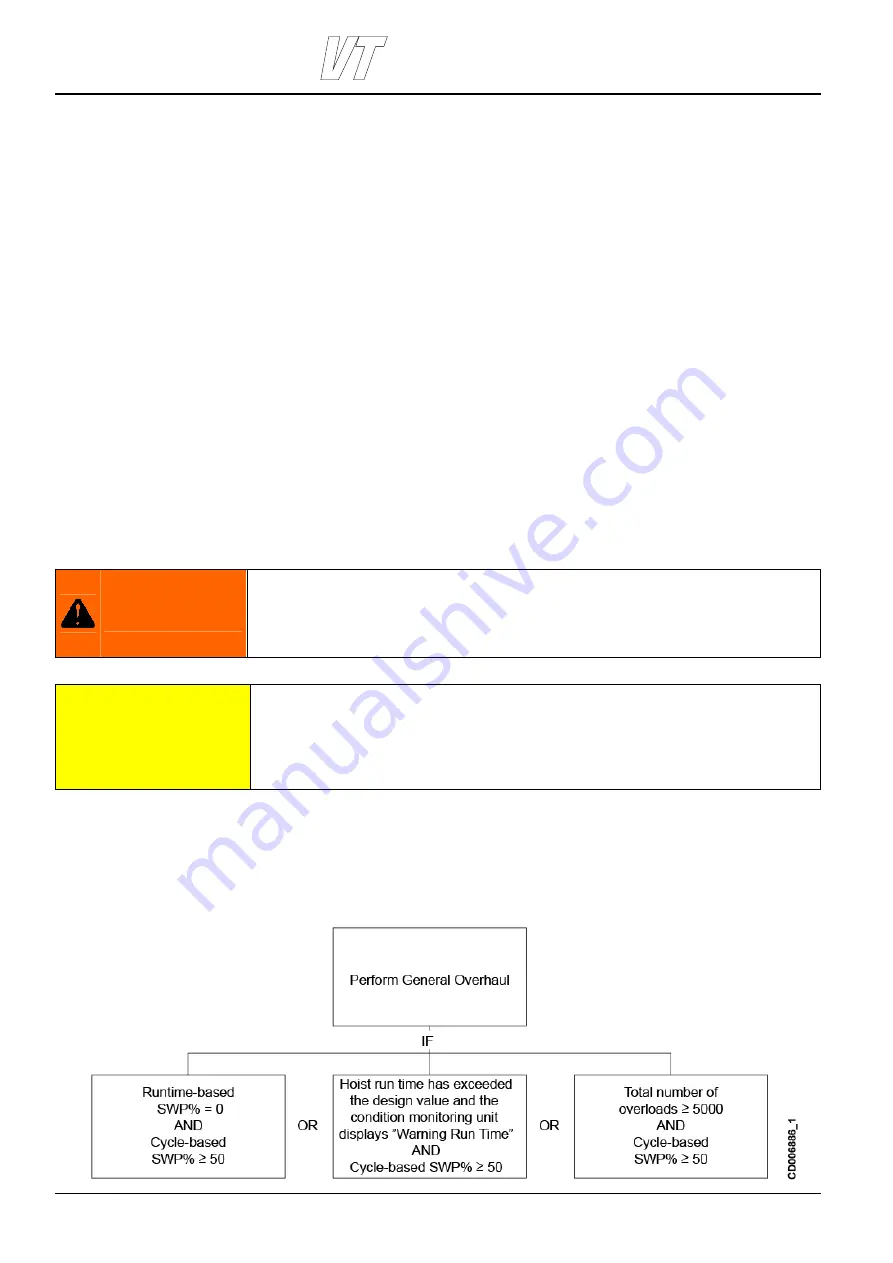

5.3.1 General Overhaul

In the GO service, the product is assigned with a new, runtime-based SWP, provided that it is safe to continue the

operation. The runtime-based SWP means the lifetime of the interchangeable rotating components of the hoist like

hoisting gear, hoisting motor, and rope sheaves. Note that in case of hoists with a smaller drum size, it is often

more cost-efficient to replace the hoist with a new one.

WARNING

When the Safe Working Period (SWP) of the hoist has decreased to zero or is

counting in the negative, the hoist may only be used after a GO service has

been conducted, or the hoist must be replaced with a new one. Any usage of a

defective hoist can result in serious damage, injury, or death.

CAUTION

When performing General Overhaul, the construction of the hoist may not be

changed or the supporting structures repaired without permission from the

manufacturer. If there are any deformations, cracks or corrosion in the

supporting structures of the hoist, the parts have to be replaced or repaired

according to the instructions given by the manufacturer.

Only authorized service personnel or an experienced service man that is authorized by the manufacturer or

manufacturer representative may conduct a General Overhaul service.

The following figure summarizes the conditions based on which General Overhaul can be performed.