2. INSTALLATION

2 - 4

2.3 Encoder cable stress

(1) The way of clamping the cable must be fully examined so that bending stress and cable's own weight

stress are not applied to the cable connection.

(2) For use in any application where the servo motor moves, fix the cables (encoder, power supply, and

brake) with having some slack from the connector connection part of the servo motor to avoid putting

stress on the connector connection part. Use the optional encoder cable within the bending life range.

Use the power supply and brake wiring cables within the bending life of the cables.

(3) Avoid any probability that the cable insulator might be cut by sharp chips, rubbed by a machine corner or

stamped by workers or vehicles.

(4) For installation on a machine where the servo motor moves, the flexing radius should be made as large

as possible. Refer to section 10.4 for the bending life.

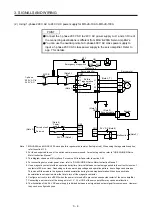

2.4 Inspection items

WARNING

Before starting maintenance and/or inspection, turn off the power and wait for 15

minutes or more until the charge lamp turns off. Otherwise, an electric shock may

occur. In addition, when confirming whether the charge lamp is off or not, always

confirm it from the front of the servo amplifier.

To avoid an electric shock, only qualified personnel should attempt inspections.

For repair and parts replacement, contact your local sales office.

CAUTION

Do not perform insulation resistance test on the servo amplifier. Otherwise, it may

cause a malfunction.

Do not disassemble and/or repair the equipment on customer side.

It is recommended that the following points periodically be checked.

(1) Check for loose terminal block screws. Retighten any loose screws.

(2) Check the cables and the like for scratches or cracks. Inspect them periodically according to operating

conditions especially when the servo motor is movable.

(3) Check that the connector is securely connected to the servo amplifier.

(4) Check that the wires are not coming out from the connector.

(5) Check for dust accumulation on the servo amplifier.

(6) Check for unusual noise generated from the servo amplifier.

(7) Make sure that the emergency stop circuit operates properly such that an operation can be stopped

immediately and a power is shut off by the emergency stop switch.

Summary of Contents for MR-JE-_A

Page 9: ...A 8 MEMO ...

Page 15: ...6 MEMO ...

Page 29: ...1 FUNCTIONS AND CONFIGURATION 1 14 MEMO ...

Page 139: ...4 STARTUP 4 38 MEMO ...

Page 187: ...5 PARAMETERS 5 48 MEMO ...

Page 221: ...6 NORMAL GAIN ADJUSTMENT 6 34 MEMO ...

Page 259: ...8 TROUBLESHOOTING 8 8 MEMO ...

Page 265: ...9 DIMENSIONS 9 6 MEMO ...

Page 273: ...10 CHARACTERISTICS 10 8 MEMO ...

Page 339: ...12 COMMUNICATION FUNCTION MITSUBISHI ELECTRIC GENERAL PURPOSE AC SERVO PROTOCOL 12 34 MEMO ...