Summa Series Servodrive Product Manual

Tuning

Document Version: V1.01

(Dec, 2019)

© 2019 ESTUN Automation Co., Ltd. All right reserved.

9-28

If you keep the default setting of Pn162, you can use a low-pass filter to eliminate the noise and high-

frequency band, in this case, you shall set Encoder Speed Filter Time (Pn135) as a proper value.

Increase the setting of Pn135, the filtering effect will be better, and the encoder feedback speed will be

smooth, but the phase lag of the speed feedback is also larger, which can reduce the servo performance.

Parameter Setting

Meaning

When Enabled

Classification

Pn135

-

Encoder Speed Filter Time

Immediately

Adjustment

9.5

Additional Adjustment Functions

9.5.1

Gain Switching

Function Description

The gain switching function can be used for the manual tuning. It is required to switch from 1st gain

parameters to 2nd gain parameters for the Servo operation in a specific stage, so that the overall

performance of the Servo system can reach the desired performance.

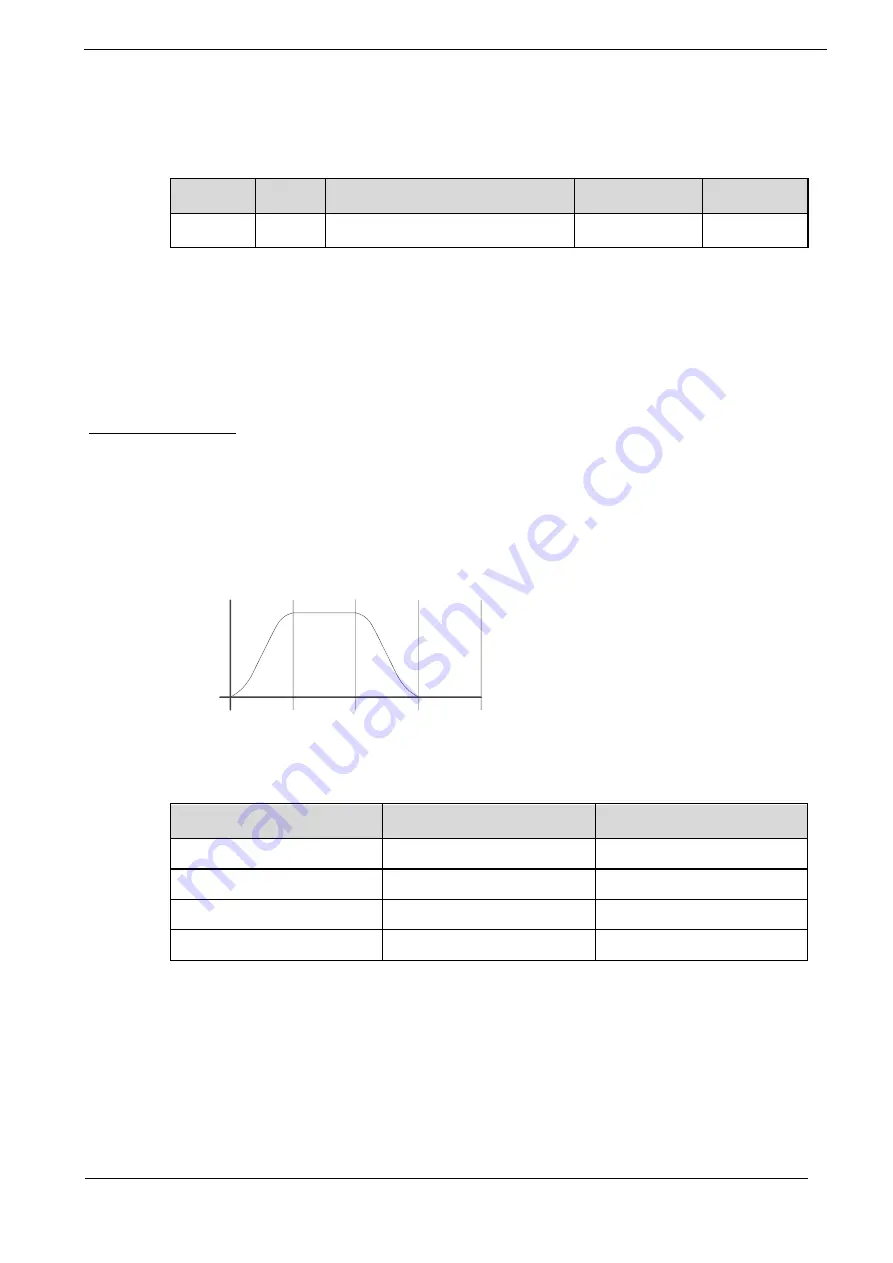

Take Figure 9-11 as an example, the position stage focuses on the performances such as position ripples

and positional rigidity, while the moving stage focuses on the performance such as following error. In

this case, two switchable groups of gain parameters are required to meet the Servo performance.

Figure 9-11

Gain switching example

Position

Moving

stage

1st gain 2nd gain

1st gain 2nd gain

Positioning

stage

Moving

stage

Positioning

stage

The parameters of the first gain and the second gain are as follows.

Parameter

First Gain

Second Gain

Speed Loop Gain

Pn102

Pn107

Speed Loop Integral Time

Pn103

Pn108

Position Loop Gain

Pn104

Pn109

Torque Command Filter Time

Pn105

Pn110

The gain switching function includes two settings: one is the conditions for starting the gain switching

and the other is which process to start the gain switching. Figure 9-12 shows a timing diagram for the

gain switching.