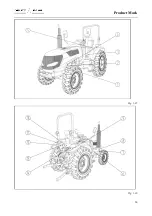

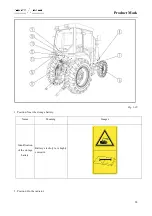

Product Mark

47

●

Remove key of the ignition lock.

●

Electrical equipment can be repaired after disconnecting

the bond strap of the storage battery.

●

When the tractor is being repaired by using electric

welding, the bond strap of the storage battery must be

disconnected, large connection plugs of engine,

hydraulic computer controller (if have) will be removed,

otherwise, it is easy to damage the storage battery,

controller and combined instrument.

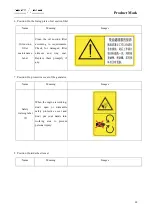

Fig. 1-28

●

High pressure hydraulic oil is powerful enough to

penetrate and hit hand, eye and skin. Therefore, pressure

of the hydraulic system will be discharged before

checking and repairing hydraulic pipelines. Then,

cardboard or wood plate will be used to check suspicious

leakage parts to prevent hands and body from being

damaged by high pressure liquid.

●

If you are injured by leaked hydraulic oil, you shall

immediately seek for medical treatment. If you don’t get

timely necessary treatment, it may cause serious

infection and reaction.

Fig. 1-29

●

Tire will be removed before welding or repairing wheel or wheel rim. Under any circumstance, if you don’t

have necessary equipment or experience for conducting this work under complete safety premise, please

contact your authorized service center.

●

Tightness of all nuts and bolts will be regularly checked, especially tightening torque of wheel and wheel rim

to prevent overturning over, serious injury of operator and excessive damage of machine due to tire falling

when the machine is working. Fasten stipulated torque (torque value is shown in the part of “tightening torque

of nut /bolt of wheel” of wheel chapter and part of “table of tightening torque of main bolts and nuts” in the

appendix chapter).

6.4.

Loosen the cover of the radiator

Summary of Contents for FL35-70HP Series

Page 21: ...Product Mark 20 1 Security Considerations ...

Page 57: ...Product Mark 56 Fig 1 35 Fig 1 36 ...

Page 58: ...Product Mark 57 Fig 1 37 Fig 1 38 ...

Page 70: ...69 2 Product Mark ...

Page 74: ...73 Page Left Intentionally Blank ...

Page 75: ...Product Description 74 3 Product Description ...

Page 77: ...Product Description 76 Fig 3 2 3 1 2 Appearance of tractor equipped with cab ...

Page 81: ...Product Description 80 ...

Page 113: ...Product Description 112 ...

Page 124: ...Electrical system 123 4 Operation Instructions ...

Page 157: ...Electrical system 156 ...

Page 162: ...Electrical system 161 Fig 4 32 Three point linkage Model 2 ...

Page 189: ...Electrical system 188 5 Wheels ...

Page 208: ...Electrical system 207 6 Electrical System ...

Page 230: ...Electrical system 229 requirements 6 6 Electrical Schematic Diagram ...

Page 235: ...234 7 On board Spare Parts Tools and Quick wear Parts ...

Page 241: ...240 ...

Page 242: ...241 8 Maintenance Specification ...

Page 288: ...287 Fig 8 35 ...

Page 338: ...Operation Instructions 337 9 Troubleshooting ...

Page 353: ...352 10 Tractor Storage and Unpack ...

Page 358: ...Tractor Storage and Unpack 357 11 Delivery Acceptance and Transportation ...

Page 361: ...360 ...

Page 362: ...361 12 Disassembly and Disposal ...

Page 365: ...Warranty Contents 364 13 Warranty Contents ...

Page 411: ...Appendix 410 15 Appendix ...