Chapter 6 - Parameter Description [FU2]

6-23

Conditions for Sensorless Vector Control

Conditions for sensorless control are as follows. If one of

the following conditions is not satisfied, the inverter may

malfunction with insufficient torque, irregular rotation, or

excessive motor noise. It is recommended to use V/F

control.

Use a motor capacity that is equal to or one

horsepower level lower than the inverter capacity.

Two different motor parameters can be set for one

inverter, but use only one motor parameter for

sensorless control.

If the motor in use is not

CMC 220V/440V Class motor

or

using 220V/380V dual use motor, utilize the auto

tuning feature in FU2-40 [Auto tuning] before starting.

Set appropriate values for the electronic thermal

function, the overload limit function and the stall

prevention. The set values should not exceed 150%

of the rated motor current.

When

DRV–04

[Frequency Mode] is set to “V1”, “I”, or

“V1+I”, eliminate any potential noise influence with

the frequency reference.

Pole number of the motor should be 2 pole, 4 pole, or

6 pole.

The distance between the inverter and the motor

should not exceed 100m (328 ft).

Precautions When Using Sensorless Control

Forced-cooling should be used for the motor when

the average operating speed is under 20Hz and more

than 100% load is used constantly.

The motor may rotate 0.5% faster than the maximum

speed if the motor temperature does not reach

normal operating temperature.

The performance can be improved during

regeneration for systems with frequent acceleration

and deceleration operations by installing the DB

(Dynamic Brake) braking unit option.

Utilize the auto-tuning feature when the motor

reaches normal temperature (average temperature

where the motor normally operates).

Output torque may be reduced when an output filter

option is used between the inverter and the motor.

Speed change is more frequent than the V/F control.

If the speed changes excessively when the FU2–38

[Carrier Frequency Selection] is set to a value more

than 10kHz, change the setting to 5~10kHz.

Over current fault can occur if the FU2-41 [Stator

Resistance (Rs)] is set to a value more than twice the

auto tuned value

Max setting range is

300 Hz.

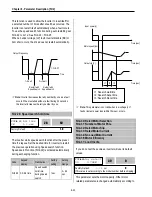

Detail Tuning Method for Sensorless Vector Control

Adjust the

FU2–34 [No Load Motor Current (RMS)]

value

larger or smaller by 5% units if the current is larger or

smaller than that of V/F control with small load.

Adjust the

FU2–32

[

Rated Motor Slip

] value larger or

smaller by 5% units if the speed is faster or slower

than that of V/F control with small load.

Sensorless_T(Sensorless Vector Torque) Operation

:

Vector_TRQ(Vector control torque) Operation:

All settings are the same as Vector_SPD except

using torque reference for torque control.

Summary of Contents for 30 HP30

Page 6: ......

Page 12: ......

Page 16: ...Chapter 1 Installation 1 4 BLANK ...

Page 18: ...Chapter 1 Installation 1 6 BLANK ...

Page 28: ...Chapter 1 Installation 1 16 Notes ...

Page 39: ...Chapter 2 Operation 2 11 Notes ...

Page 40: ......

Page 46: ......

Page 60: ...Chapter 4 Operation Examples 4 14 Notes ...

Page 83: ...Chapter 5 Parameter List 5 23 Notes ...

Page 84: ......

Page 92: ...Chapter 6 Parameter Description DRV 6 8 Notes ...

Page 105: ......

Page 106: ...Chapter 6 Parameter description FU1 6 14 Notes ...

Page 126: ...Chapter 6 Parameter Description FU2 6 34 Notes ...

Page 144: ...Chapter 6 Parameter Description I O 6 52 Notes ...

Page 162: ......

Page 188: ...Chapter 7 Options 7 26 Type 1 Max 400 Watt Type 2 Max 600 Watt A ...

Page 189: ...Chapter 7 Options 7 27 Type 3 ...

Page 194: ......

Page 204: ......

Page 210: ......