2.4 I/O Unit (JZRCR-XCO02B)

2-21

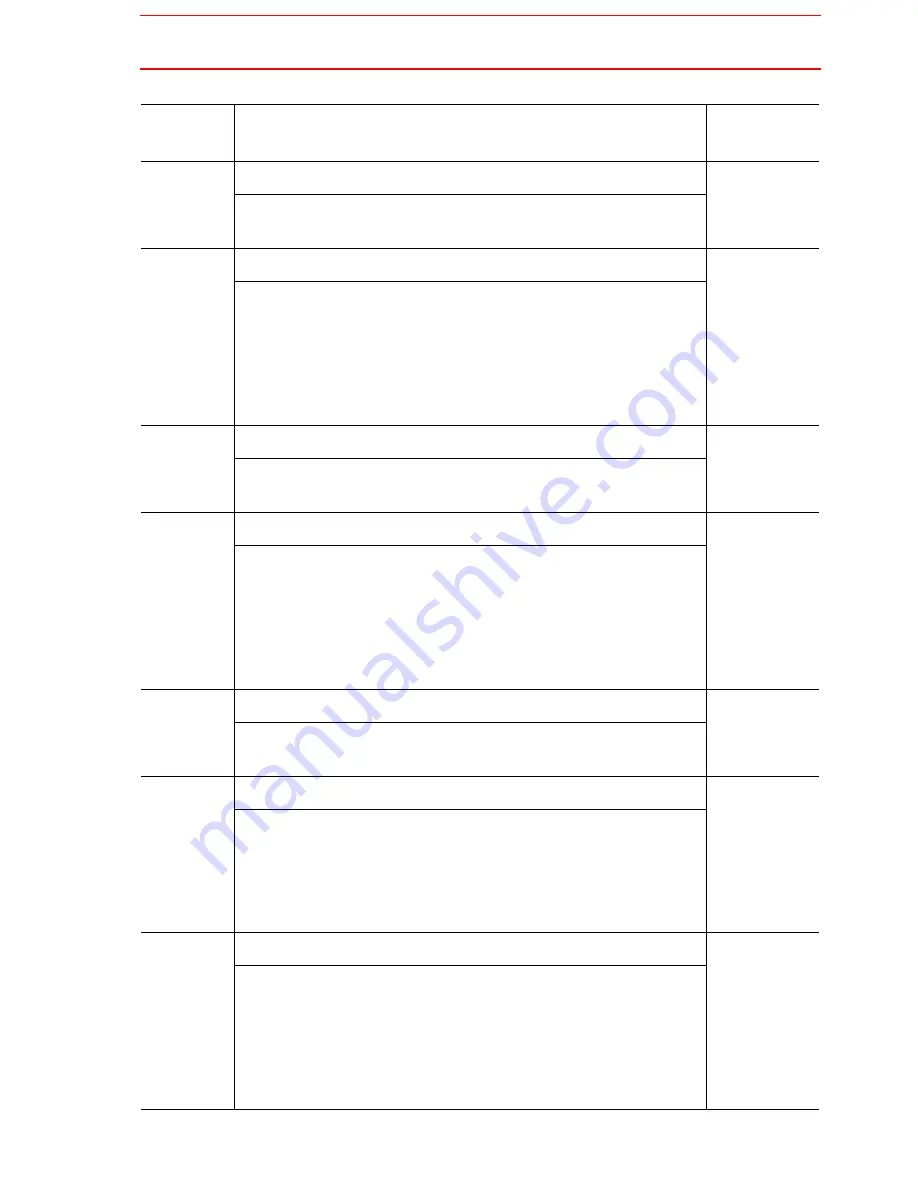

DIN

CN44 -7

-8

Direct-in 4

Open

Direct-in4 is for future use.

FORCE1

CN40 -1

-2

FORCE2

CN40 -3

-4

Forced reset input

Open

Do not use the “FORCE” (Forced release) input.

If the “FORCE” input should be used for an unavoidable reason, be

sure to use a switch with a key. The systems manager is responsible

for storage of the key.

When “FORCE” is input, all the deadman switches become invalid,

so handle with extreme care.

RDY

CN06-11

-12

Optional board Ready signal

Disabled by

Jumper lead

Use to add safety circuit conditions.

FST1

CN40 -5

-6

FST2

CN40 -7

-8

Full-speed test

Open

PLAY normal speed is selected in PLAY mode, and TEACH normal

speed is selected in TEACH mode.

S-SP1

CN40 -9

-10

Switches Valid/Invalid of HSW/DSW.

Open

When open, DSW valid

When short-circuited, HSW valid

S-SP2

CN40-11

-12

Switches between 1st Safety Speed and 2nd Safety Speed.

Open

1st Safety Speed: the speed is limited to 16 % of PLAY maximum

speed.

2nd Safety Speed: the speed is limited to 2 % of PLAY maximum

speed.

When open, 1st Safety Speed is selected

Whe short-circuited, 2nd Safety Speed is selected.

HSW1

CN40-13

-14

HSW2

CN40-15

-16

Hanger switch

Open

Validates the hanger switch with S-SP1 short-circuited.

When open, a normal speed

When short-circuited, a safety speed (according to the setting of S-

SP2)

Specific Input List (XCO02B)

Terminal

Input Name / Function

Factory

Setting

Содержание SK300X

Страница 2: ......

Страница 4: ...SK300X Manipulator Manual XRC 2001 ii MOTOMAN NOTES...

Страница 7: ...INTRODUCTION MOTOMAN 1 3 SK300X Manipulator Manual XRC 2001 NOTES...

Страница 21: ...viii...

Страница 25: ...xii...

Страница 41: ...1 7 Notes on MOTOMAN Disposal 1 16...

Страница 59: ...4 3 Connection Methods 4 12...

Страница 67: ...6 1 Movement of the Axes 6 4...

Страница 73: ...8 2...

Страница 74: ......

Страница 93: ...3 3 Location 3 6...

Страница 99: ...4 2 Cable Connection 4 6...

Страница 102: ...5 4 Dimensions and Working Range 5 3 5 4 Dimensions and Working Range Fig 10 a Dimesions and Working Range YR SK300 J0...

Страница 103: ...5 4 Dimensions and Working Range 5 4 Fig 10 b Dimesions and Working Range YR SK300 J1...

Страница 104: ...5 4 Dimensions and Working Range 5 5 Fig 10 c Dimesions and Working Range YR SK300 J2...

Страница 109: ...6 2 Wrist Flange 6 4...

Страница 133: ...9 2 Notes on Maintenance Procedures 9 18...

Страница 136: ...11 1 S Axis Driving Unit 11 1 11 Parts List 11 1 S Axis Driving Unit...

Страница 138: ...11 2 L U Axis Driving Unit 1 11 3 11 2 L U Axis Driving Unit 1...

Страница 140: ...11 3 L U Axis Driving Unit 2 11 5 11 3 L U Axis Driving Unit 2...

Страница 234: ...2 8 General I O Signal Assignment 2 72...

Страница 270: ...4 4 Recommended Spare Parts 4 30...

Страница 285: ...xiv...

Страница 286: ...Setup Diagnosis...

Страница 287: ......

Страница 289: ...1 2...

Страница 297: ...2 1 Protection Through Security Mode Settings 2 8...

Страница 395: ...3 17 File Initialize 3 98...

Страница 417: ...4 2 Addition of Base and Station Axis 4 22...

Страница 435: ...5 6 Position Data When Power is Turned ON OFF 5 18...

Страница 436: ...Hardware...

Страница 437: ......

Страница 447: ...6 4 Equipment Configuration 6 10...

Страница 456: ...8 8 Open Phase Check 8 8...

Страница 476: ...9 4 Recommended Spare Parts 9 20...

Страница 477: ...Alarm Error...

Страница 478: ......

Страница 523: ......

Страница 524: ......

Страница 525: ......

Страница 526: ......

Страница 527: ......

Страница 528: ......

Страница 529: ......

Страница 530: ......

Страница 531: ......

Страница 532: ......

Страница 533: ......

Страница 534: ......

Страница 535: ......

Страница 536: ......

Страница 537: ......

Страница 538: ......

Страница 539: ......

Страница 540: ......

Страница 541: ......

Страница 542: ......

Страница 543: ......

Страница 544: ......

Страница 545: ......

Страница 546: ......

Страница 547: ......

Страница 548: ......

Страница 549: ......

Страница 550: ......

Страница 551: ......

Страница 552: ......

Страница 553: ......