Sigma II User’s Manual

Chapter 3: Wiring

3 - 31

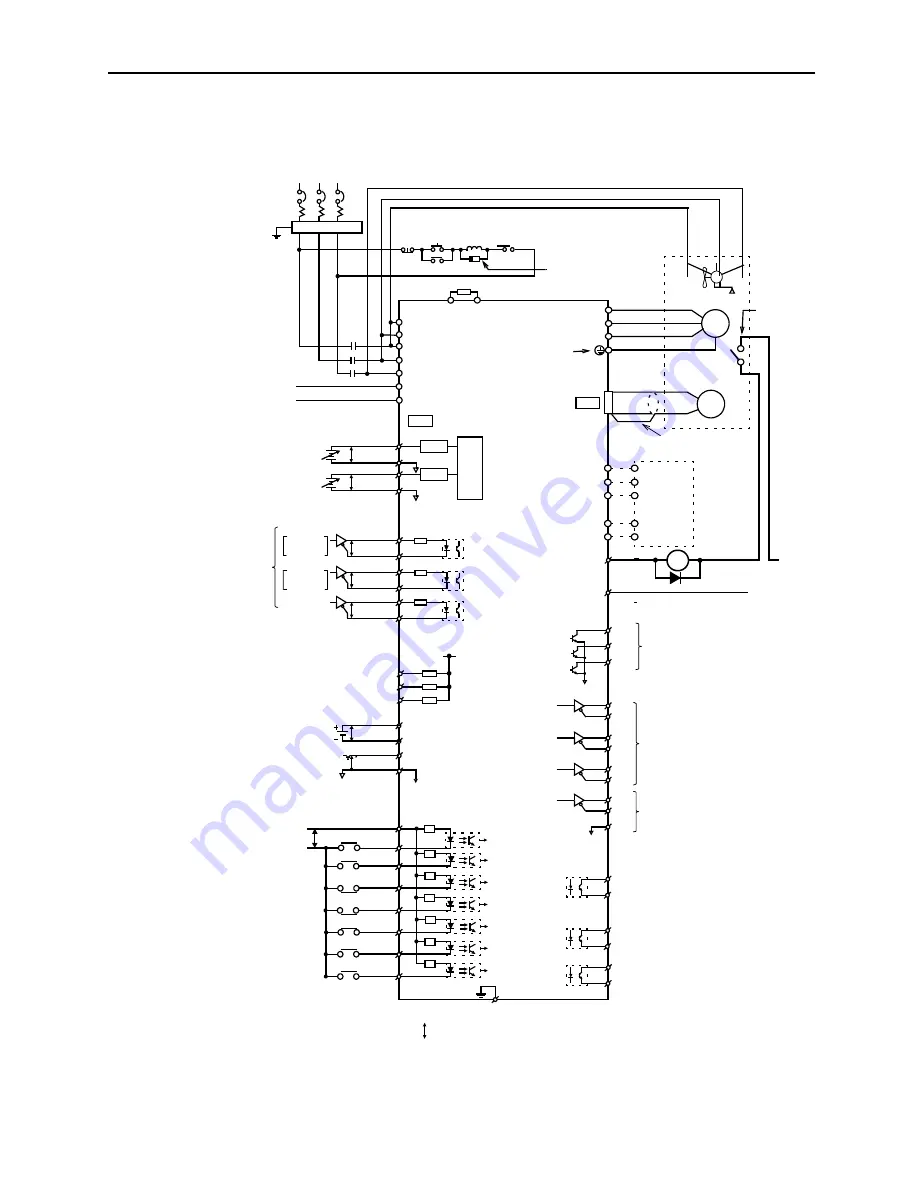

400V (37kW to 55kW)

Photocoupler maximum output:

Operating voltage: 30V

DC

Operating current: 50mA

DC

Reference speed:

±2V to ±10V/rated speed (set by parameter)

Torque reference:

±1 to ±10V/rated torque (set by parameter)

Alarm code maximum output:

Operating voltage: 30V

DC

Operating current: 20mA

DC

P: Indicates twisted wire pairs.

1CN

PG

M

Noise filter

SGDH Servo Amplifier

Three-phase 380 to 480V

ac

(50/60Hz)

R

S

T

1MCCB

Power Power

1MC

1MC

1MC

SUP

Be sure to attach a

B1

B2

L1/R

L2/S

U

V

DC24P

DC24N

L3/T

W

PULS

/PULS

PULS

P

SIGN

CLR

7

/SIGN

P

P

/CLR

8

11

12

15

14

150W

38

39

33

34

35

36

19

20

49

1

48

37

25

26

27

28

29

30

31

Used only with

an absolute encoder

Servo ON

Proportional (P) control

Forward run

Reverse run

Alarm reset

Forward current

/V-CMP+

/T-GON+

/S-RDY+

/S-RDY-

/T-GON-

/V-CMP-

Reverse current

prohibited

prohibited

limit ON

limit ON

ALO1

ALO2

ALO3

PAO

/PAO

PBO

/PBO

PCO

/PCO

PSO

/PSO

SG

Amount of S-phase rotation

PG dividing ratio output

Be sure to properly

Optical

prepare the end of

Servomotor

encoder

Applicable line receiver

SN75175 or MC3486 manufac-

tured by T/I, or the equivalent

Serial data output

Applicable line receiver

SN75175 or MC3486 manufac-

tured by T/I, or the equivalent

Positioning completed

(ON when positioning is

completed)

T-GON output

Servo ready output

(ON at levels above the setting)

(ON when ready)

Connect shield to connector shell

Connector shell

Position reference

CW

CLR

Phase A

A (1)

B (2)

C (3)

D (4)

Be sure to

ground

OFF

ON

1Ry

ALM

+

FG

(/COIN+)

(/COIN-)

Speed coincidence detection

(ON when speed coincides)

Fan

U(A) V(B) W(C)

Regenerative Resistor

the shielded wire.

1

1B

+24V

1Ry

1D

0V

ALM

-

32

0V

+10

-15 %

DU

DW

DV

DBON

DB24

Dynamic

Brake

*The time constant for the primary filter is 47

μ

s

2CN

SIGN

CCW

Phase B

surge suppressor to

the excitation coil of

the magnetic contactor

and relay.

P

LPF*

P

LPF*

V-REF

9

10

5

6

SG

T-REF

SG

A/D

24V

DC

+10% maximum

PL1

PL2

3

13

18

PL3

+12V

Open-collector

reference

power supply

Backup battery 2.8 to 4.5V

(When using an absolute encoder).

SEN signal input

(When using an absolute encoder).

21

BAT (+)

P

SEN

SG

22

4

2

47

40

41

42

43

44

45

46

P

BAT (-)

+24V

+5V

0V

+24V

/S-ON

/P-CON

P-OT

N-OT

ALM-RST

/P-CL

/N-CL

Forward run prohibited with

Reverse run prohibited with

Alarm reset with 3Ry ON

P control with 2Ry ON

Reverse current limit ON with 7Ry ON

Forward current limit ON with 6Ry ON

N-LS OPEN

P-LS OPEN

Servo ON with 1Ry ON

24V

DC

±15%

1Ry

2RY

P-LS

N-LS

3Ry

6Ry

7RY

4.7k

Ω

380 ~ 480V

OV

**Note The thermal protector must be

wired to provide protection in the

event of the motor overheating.

**Thermal

Protector

Summary of Contents for SGMAH

Page 1: ...Sigma II Series Servo System User s Manual...

Page 2: ......

Page 4: ...ii This page intentionally left blank...

Page 6: ...iv This page intentionally left blank...

Page 10: ...Sigma II User s Manual Table of Contents Preface viii Notes...

Page 17: ...Sigma II User s Manual Table of Contents Preface xv C 6 Torque Control Mode C 9...

Page 18: ...Sigma II User s Manual Table of Contents Preface xvi...

Page 38: ...Sigma II User s Manual Chapter 2 Installation 2 10 NOTES...

Page 472: ...Sigma II User s Manual Appendix C Examples of Standard Connections C 10 Notes...

Page 487: ......