Engine, clutch and transmission 2»23

91

Jr **-*"

1

%/

V

2k

/ .,■

■>: j

I A

^A ®J

^

•gC^vT

' tJ/^k

/^MsR^

!

/

fcV

M

^3^r~~

s

........... .--

>^B|

*Sf

;;

.*>jOm^'

prr

^

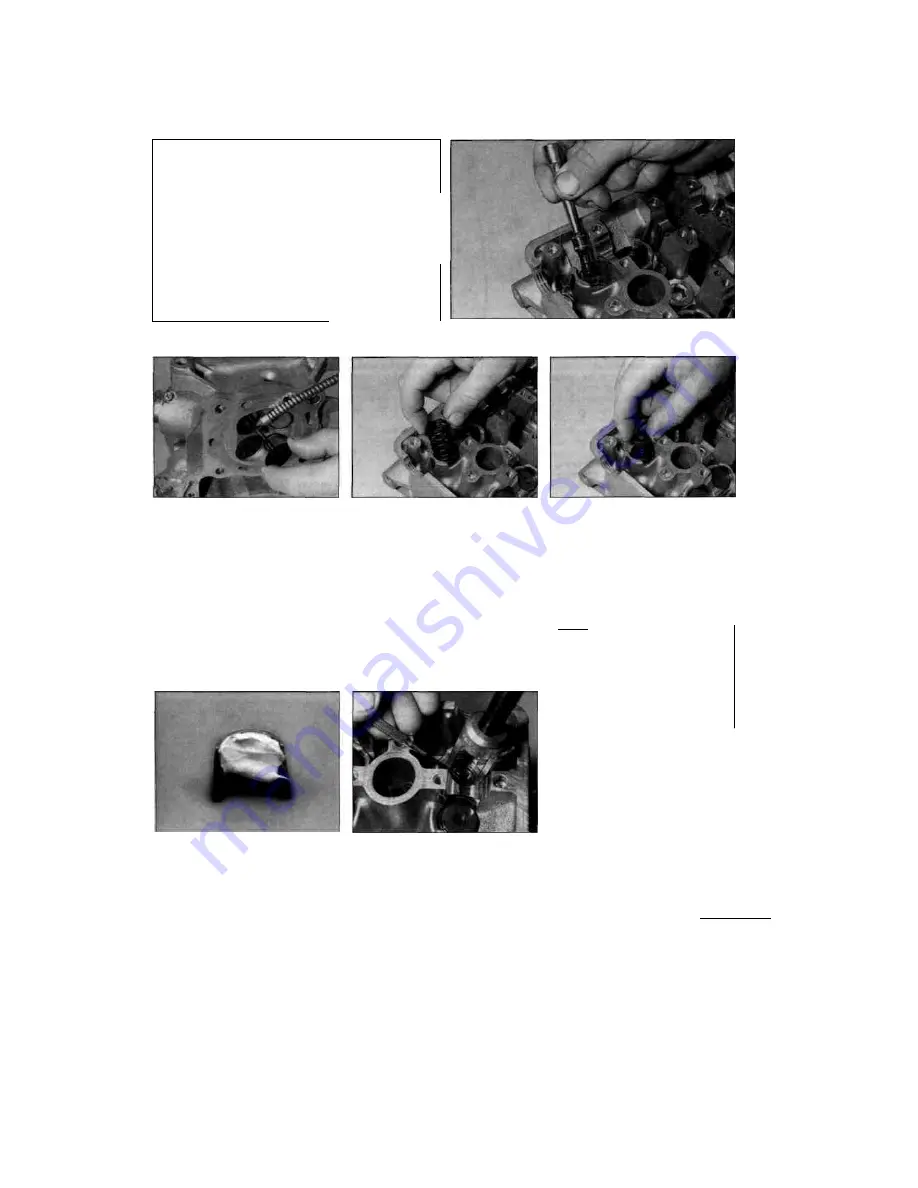

12.25a Fit the spring seat...

12.25b ... then press the valve stem seal into position using a

suitable deep socket

12.26a Lubricate the stem and slide the

valve into its correct location

in the cylinder head, with its shouldered side up

so that the spring fits into it, then install new

valve stem seals on each of the guides

(see

illustrations).

Use an appropriate size deep

socket to push the seals over the end of the

valve guide until they are felt to clip into place.

Don't twist or cock them, or they will not seal

properly against the valve stems. Also, don't

remove them again or they will be damaged.

26 Coat the valve stems with molybdenum

disulphide grease, then install one of them into

its guide, rotating it slowly to avoid damaging the

seal

(see illustration).

Check

12.27a A small dab of grease will help to

keep the collets in place on the valve while

the spring is released

12.26b Fit the valve spring with its closer-

wound coils facing down.

..

that the valve moves up and down freely in the

guide. Next, install the spring, with its closer-

wound coils facing down into the cylinder head,

followed by the spring retainer, with its

shouldered side facing down so that it fits into

the top of the spring

(see illustrations).

27

Apply a small amount of grease to the collets

to help hold them in place as the pressure is

released from the springs

(see illustration).

Compress the springs with the valve spring

compressor

and

install

the

collets

(see

illustration).

When compressing the spring,

depress them only as far as is

12.27b Compress the spring and install

the collets, making sure they locate in the

groove

14.26c ... then fit the spring retainer

absolutely necessary to slip the collets into place.

Make certain that the collets are securely locked

in their retaining grooves. 28 Support the cylinder

head on blocks so the valves can't contact the

workbench top, then very gently tap each of the

valve stems with a soft-faced hammer. This will

help seat the collets in their grooves.

fffffflgjl

Check for proper sealing of

""J""

the

valves by pouring

a

HlRIT

small amount of

solvent into

----------

each

of the valve ports. If

the solvent leaks past any valve into the

combustion chamber area the valve

grinding operation on that valve should be

repeated.

13 Cylinder block

-removal,

inspection and installation

Note:

The cylinder block can be removed

with the engine in the frame.

Removal

1 Remove the cylinder head (see Section 10).

2 Unscrew the bolts securing the coolant hose

union to the front of the block and

Staned by Stalker

1