SERVICE MANUAL

5–80

10FEB97 – SM3226-1

PH3 S Magazine Door Sensor

Note

This procedure cannot be done on machines after S/N 500249. DETECTORS were changed from PHOTO

DETECTORS to MICROSWITCHES to comply with European standards.

To Check:

[1] Install the PORTABLE COMPUTER. See

“Using the Portable Computer” in the Diagnostic

Section.

[2] Use the PORTABLE COMPUTER to display the

CES Main Menu.

[3] Enter [1] for “Monitor Mode”.

[4] Enter [5] for “Sensors”.

[5] Remove the RIGHT IMAGE UNIT COVER. If necessary, see the procedure on Page 2–3.

[6] On the PORTABLE COMPUTER, check that the S MAGAZINE DOOR SENSOR PH3 reads 0 when the

DOOR is closed, and 1 when the DOOR is open.

To Adjust:

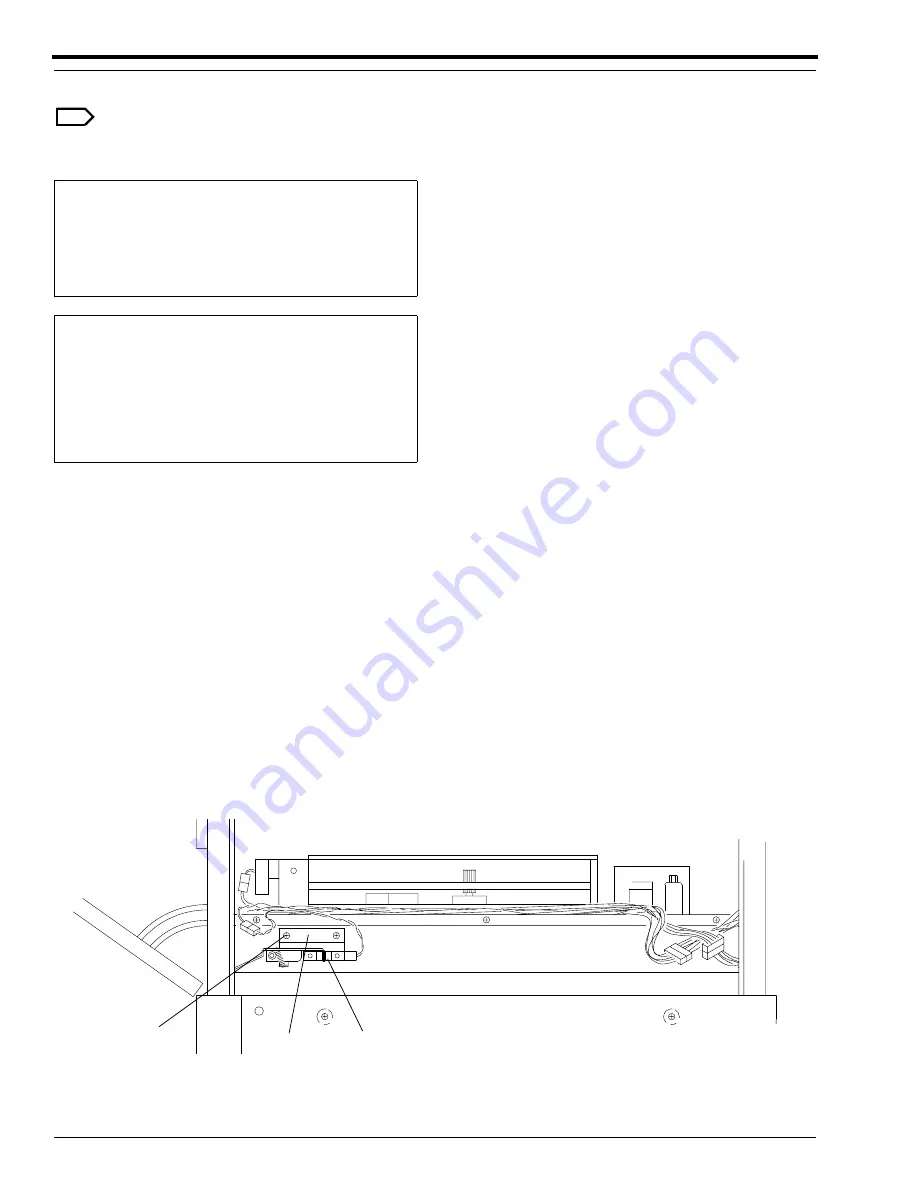

[7] Loosen the 2 SCREWS.

[8] Move the SENSOR BRACKET until the SENSOR reads 0 when the DOOR is closed and 1 when the DOOR

is open.

[9] Tighten the 2 SCREWS.

MAIN MENU

1 Monitor Mode 4 System Params

2 System Logs 5 Debug Utility

3 Boards Diag 6 Exit

Enter Menu Item:

MONITOR MODE MENU

1 Motors 6 Seq Board Diag

2 Solenoids 7 Enter Commands

3 Relay 8 Set Beam-Splitter

4 Miscellaneous 9 Auto Sensor Test

5 Sensors 10 Semi-Auto Sensor Test

Enter Menu Item:

H129_1908BC

H129_1908BCC

SCREW (2)

SENSOR

BRACKET

R MAGAZINE

DOOR SENSOR