103

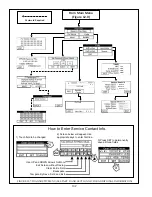

2) Current Priority Screen:

a) Current

Demand

- The demand to which the boiler is currently responding. If more than one demand is present, it is the

#) %## %# )& &! "&

b) Setpoint

- The temperature that the boiler is currently trying to achieve.

c) Supply (or Header) Temperature

- The actual water temperature at the current setpoint location (either the boiler

#&\&& %#&&&'# '& #"% `

d) Setpoint

Source

- Should always read “Local S.P.” in the applications covered by this manual.

3) Boiler

Temperatures

Screen:

a) Supply

- Current water temperature at boiler supply sensor.

b) Return

- Current water temperature at boiler return sensor.

c) Stack

"% )

d) Header

- Current header sensor temperature. This temperature will only be visible if the header was selected as the

#"%

4) Burner Status Screen:

a) Burner

Status

- Indicates what the burner system is currently doing. Typical Burner Status include:

+

Standby -

Burner is not needed because there is no call for heat or the target temperature has been reached.

+

Standby Delay

- Burner is needed, but is being temporarily held off (generally due to a soft lockout - see

Diagnostics section).

+

Safe Start-up

" # % % % (

+

Drive Purge

- Waiting for blower to reach pre-purge speed.

+

Prepurge

' %#' &%%# #_`

+

Drive Light-off

- Waiting for blower to prove that it is at the proper ignition fan speed.

+

Pre-ignition test

- Test the safety relay and verify that downstream contacts are off.

+

Pre-ignition

% { % ' #%))## %

+

Direct ignition

] ## % % {&\#%))&##~

for ignition period is

4s

.

+

Running

%

+

Post-Purge

- Blower is running after the burner shuts off to clear the combustion chamber of residual gasses. Post

purge time is 30s.

+

Lockout

- Boiler is in a hard lockout (see Diagnostic Section).

b) Active

Fault

_) '## `)# & ' ## #

Touching this indicator takes the user to the Diagnostic Menu. See Section XIV for more information.

c) Hold Delay (Visible only during soft lockout)

- Indicates remaining time before next ignition sequence.

d) Flame

Signal

& #%## % "

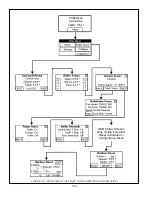

Summary of Contents for PHNTM080

Page 2: ......

Page 9: ...7 Figure 4 1 Minimum Clearances To Combustible Construction...

Page 11: ...9 Figure 5 1 Wall Layout Mounting Hole Location...

Page 12: ...10 Figure 5 2 Boiler Mounting Bracket Installation Boiler Wall Mounting...

Page 39: ...37 FIGURE 7 24 SPLIT VENT SYSTEM FLEX IN ABANDONED MASONRY CHIMNEY VENT OPTIONS 33 38...

Page 63: ...61 This page is intentionally left blank...

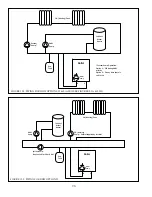

Page 68: ...66 FIGURE 9 2 PIPING METHOD 1 NEAR BOILER PIPING HEATING ONLY...

Page 72: ...70 FIGURE 9 6 PIPING METHOD 1 NEAR BOILER PIPING SHADED BOILER LOOP...

Page 82: ...80 FIGURE 10 4 PROPER INSTALLATION OF HEADER SENSOR...

Page 84: ...82 FIGURE 10 6 INTERNAL WIRING CONNECTIONS DIAGRAM...

Page 85: ...83...

Page 92: ...90 Lighting and Operating Instructions...

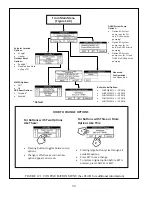

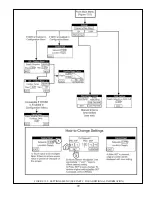

Page 101: ...99 FIGURE 12 5 SETTINGS MENU SEE PART C FOR ADDITIONAL INFORMATION...

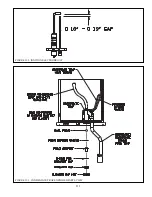

Page 113: ...111 FIGURE 13 2 IGNITION ELECTRODE GAP FIGURE 13 3 CONDENSATE TRAP EXPLODED PARTS VIEW...

Page 125: ...123...

Page 127: ...125 40 33 31 27 28 34 35 37 38 32 39 36 29 30 48 Blower Gas Valve Assembly for 80 100 120...

Page 129: ...127...

Page 131: ...129...

Page 132: ...130...

Page 133: ...131...

Page 135: ...133...

Page 137: ...135 140 141 142 143 144 145...