137

# %&~% &'+# & #

instructions if either, or both, of the following are true:

Q

&' #}%

Q

& &)+

Follow steps 1-13 below in the order they are presented.

Steps applying to only one type of conversion (LP or altitude) may

be skipped if that type of conversion is not being performed.

1) If not already done, install the boiler in accordance with this manual, following all instructions in Part XI (Start-up and

Check-out) up to Step 10.

2) LP CONVERSIONS ONLY – Set the throttle to its preliminary setting for LP. To do this:

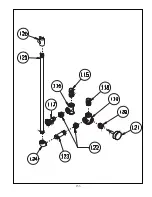

a. Turn the throttle (Figure A.1) clockwise until it stops (several full turns).

b. Turn throttle counter-clockwise the exact number of turns shown in Table A.2.

3) ALTITUDE CONVERSIONS ONLY – Control system must be set to permit operation at higher fan speeds than those used

at sea level. This is changed in the ALTITUDE MENU (Figure A.3). To change altitude setting in control:

a. From the home screen, press MENU

b. From the main menu, press CONFIGURE

c. When prompted for a password. Use the “+1” button to raise the password to 5, then press SUBMIT. If you

accidentally raise the password above 5, press EXIT to return to the main menu and start over.

& #'& &\) '#]~~&""$##%

#% \~"##&)&%

f.

Press ALTITUDE. Review the WARNING screen that follows, and press ACCEPT to reach the altitude screen.

g. Press the altitude shown to advance to the appropriate altitude (Figure A.3). Four altitude ranges can be selected:

Q

+_`

Q

+

Q

Q

+

Where the installation altitude is very close to one of these breakpoints, use the lower range.

# $# % "#&# #%'#$&# &

# %

i.

Return to the HOME screen and verify that the appropriate altitude range (in kft) is shown in the lower right corner

of

the

screen

(Fig

A.3)

` # %# %# % &%# & %##

for ignition, allow to boiler to make at least four more attempts to light. If boiler still does not light, turn the throttle

counterclockwise in 1/8 turn increments, allowing the boiler to make at least four tries for ignition at each setting, until the

boiler

lights.

` # %#\## %# %# %\& %\#! %#

Fire Hold as described in Part XI (start-up and checkout). Allow the boiler to operate for approximately 5 minutes before

% & %~;#+ \&# &# %##&

The boiler will also be released from manual input if the user manually navigates back to the home screen.

` \ %&# ##)&

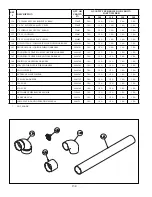

` ]# # # %#&[##&& #"+ %#' #$;

Q

$&#"+_ #+`##'

Q

$ #"+_&#+`##'

Make adjustments in increments of 1/8 to 1/4 turn and allow the boiler at least a minute to respond to each adjustment before

making another. In general, the CO level will be at its lowest somewhere in the CO2 range shown in this table. Consult

Summary of Contents for PHNTM080

Page 2: ......

Page 9: ...7 Figure 4 1 Minimum Clearances To Combustible Construction...

Page 11: ...9 Figure 5 1 Wall Layout Mounting Hole Location...

Page 12: ...10 Figure 5 2 Boiler Mounting Bracket Installation Boiler Wall Mounting...

Page 39: ...37 FIGURE 7 24 SPLIT VENT SYSTEM FLEX IN ABANDONED MASONRY CHIMNEY VENT OPTIONS 33 38...

Page 63: ...61 This page is intentionally left blank...

Page 68: ...66 FIGURE 9 2 PIPING METHOD 1 NEAR BOILER PIPING HEATING ONLY...

Page 72: ...70 FIGURE 9 6 PIPING METHOD 1 NEAR BOILER PIPING SHADED BOILER LOOP...

Page 82: ...80 FIGURE 10 4 PROPER INSTALLATION OF HEADER SENSOR...

Page 84: ...82 FIGURE 10 6 INTERNAL WIRING CONNECTIONS DIAGRAM...

Page 85: ...83...

Page 92: ...90 Lighting and Operating Instructions...

Page 101: ...99 FIGURE 12 5 SETTINGS MENU SEE PART C FOR ADDITIONAL INFORMATION...

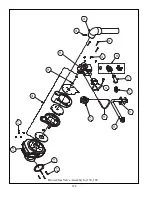

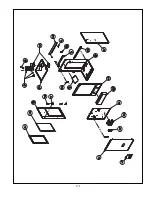

Page 113: ...111 FIGURE 13 2 IGNITION ELECTRODE GAP FIGURE 13 3 CONDENSATE TRAP EXPLODED PARTS VIEW...

Page 125: ...123...

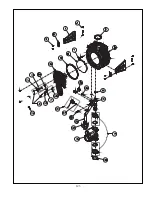

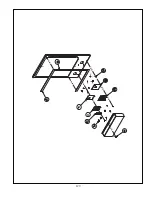

Page 127: ...125 40 33 31 27 28 34 35 37 38 32 39 36 29 30 48 Blower Gas Valve Assembly for 80 100 120...

Page 129: ...127...

Page 131: ...129...

Page 132: ...130...

Page 133: ...131...

Page 135: ...133...

Page 137: ...135 140 141 142 143 144 145...