34

Table 7.21: Summary of Split Vent System Options

Option #

25

26

27

28

29

30

Illustrated in Figure

7.22

7.22

7.22

7.22

7.22

7.22

Pipe Penetration Through

Structure

Vent

Roof

Roof

Roof

Roof

Roof

Roof

Intake

Wall

Wall

Wall

Wall

Wall

Wall

Material

Vent

CPVC/PVC

(Note 2)

CPVC/PVC

(Note 2)

DuraVent

PolyPro

(Ridgid)

DuraVent

PolyPro

(Ridgid)

Selkirk

Selkirk

Intake

PVC

PVC

PVC

PVC

PVC

PVC

Nominal Diameter

Vent

2”

3”

2”

3”

2”

3”

Intake

2” or 3”

3”

2” or 3”

3”

2” or 3”

3”

Min Equivalent Vent Length:

Models

080

48”

48”

48”

48”

48”

48”

100

48”

48”

48”

48”

48”

48”

120

Not Permitted

48”

Not Permitted

48”

48”

150

52”

52”

52”

180

52”

52”

52”

Max Equivalent Vent Length (Note 1):

Models

080

60ft

135ft

60ft

135ft

60ft

135ft

100

60ft

135ft

60ft

135ft

60ft

135ft

120

Not Permitted

135ft

Not Permitted

135ft

135ft

150

135ft

135ft

135ft

180

135ft

135ft

135ft

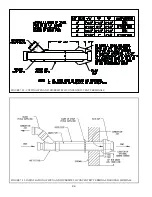

Rigid Vent Terminals

Vent

Coupling w

Screen

Coupling w

Screen

2PPS-12B or

2PPS-36B w

Screen

3PPS-12B or

3PPS-36B w

Screen

2PF-10UV or

2PF-39UV w

Screen

3PF-10UV or

3PF-39UV w

Screen

Intake

90 Elbow w

Screen

90 Elbow w

Screen

90 Elbow w

Screen

90 Elbow w

Screen

90 Elbow w

Screen

90 Elbow w

Screen

Flex Termination &

Components (Masonry

Chimney Chase) (Note 3)

Vent

Intake

Flex Termination &

Components (B-Vent

Chimney Chase)

Vent

Intake

* Specify size of B vent (e.g. 2PPS-BV

6

is for use with 6” B vent)

** Specify length in feet.

**** Specify Flex length and B vent diameter (e.g. IFBK02

2505

&+*&&' #)`

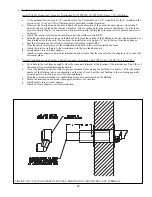

Note 1: Max vent lengths shown also apply to the intake. Flex vent reduces the maximum allowable vent length.

( )%#*)#' $& { %*%+

~+;^ *#'""

~;# && # %&#\

ALL

must be unused.

~; %\&#( &)

.

Summary of Contents for PHNTM080

Page 2: ......

Page 9: ...7 Figure 4 1 Minimum Clearances To Combustible Construction...

Page 11: ...9 Figure 5 1 Wall Layout Mounting Hole Location...

Page 12: ...10 Figure 5 2 Boiler Mounting Bracket Installation Boiler Wall Mounting...

Page 39: ...37 FIGURE 7 24 SPLIT VENT SYSTEM FLEX IN ABANDONED MASONRY CHIMNEY VENT OPTIONS 33 38...

Page 63: ...61 This page is intentionally left blank...

Page 68: ...66 FIGURE 9 2 PIPING METHOD 1 NEAR BOILER PIPING HEATING ONLY...

Page 72: ...70 FIGURE 9 6 PIPING METHOD 1 NEAR BOILER PIPING SHADED BOILER LOOP...

Page 82: ...80 FIGURE 10 4 PROPER INSTALLATION OF HEADER SENSOR...

Page 84: ...82 FIGURE 10 6 INTERNAL WIRING CONNECTIONS DIAGRAM...

Page 85: ...83...

Page 92: ...90 Lighting and Operating Instructions...

Page 101: ...99 FIGURE 12 5 SETTINGS MENU SEE PART C FOR ADDITIONAL INFORMATION...

Page 113: ...111 FIGURE 13 2 IGNITION ELECTRODE GAP FIGURE 13 3 CONDENSATE TRAP EXPLODED PARTS VIEW...

Page 125: ...123...

Page 127: ...125 40 33 31 27 28 34 35 37 38 32 39 36 29 30 48 Blower Gas Valve Assembly for 80 100 120...

Page 129: ...127...

Page 131: ...129...

Page 132: ...130...

Page 133: ...131...

Page 135: ...133...

Page 137: ...135 140 141 142 143 144 145...