24

C. Design Requirements Unique to Vertical Venting Systems

Table 7.13a summarizes all vertical twin pipe vent options. Table 7.13.b summarizes vent options in which an abandoned

B-vent chimney is used both as a chase for the vent pipe and as a conduit for combustion air.

In addition to the requirements in Part VII-A, observe the following design requirements:

1. Permitted

Terminals

for

Vertical

Venting

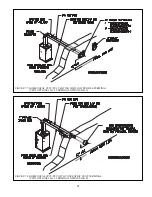

Terminal Option H: Fittings (Acceptable for Vent Options 10-17) – Vent terminates in a plain end (coupling for PVC, bell end

\& & ^` "' %&'_''|

may be substituted). Observe the clearances from the roof, and normal snow line on the roof, shown in Figures 7.15 and 7.17.

$# \^*&#&

Use of rodent screens is generally recommended for both terminations. Two rodent screens suitable for 3” PVC terminals

&' ## & &#' ^ %++"" &\#

# %&_ &%&`\&^';

Size/Vent System

Rodent Screen (“Bird Guard”)

2” Polypro

DuraVent # 2PPS-BG

3” Polypro

DuraVent # 3PPS-BG

+

+^!$

!$

2” InnoFlue

Centrotherm # IASPP02

3” InnoFlue

Centrotherm # IASPP03

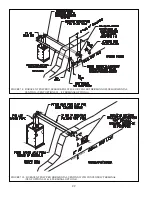

Terminal Option I: Ipex FGV Concentric Terminal (Acceptable for Vent Options 10 & 11) - This terminal is shown in Figure

&&' #""") # %& &' #

the Ipex instructions for this terminal. This terminal is available in various lengths and in both PVC and CPVC. Terminals

acceptable for use with these vent options are as follows:

Ipex

PN

FGV

Concentric

Terminal

Description

196005

2

x

16”

PVC

196105

2

x

28”

PVC

196125

2

x

40”

PVC

196006

3

x

20”

PVC

196106

3

x

32”

PVC

196116

3

x

44”

PVC

197107

3

x

32”

CPVC

197117

3

x

44”

CPVC

See Part VII-E of this manual and the Ipex instructions provided with the terminal, for installation details.

FIGURE 7.12: SNORKEL TERMINAL CONFIGURATION (CPVC/PVC VENT SYSTEMS ONLY)

Summary of Contents for PHNTM080

Page 2: ......

Page 9: ...7 Figure 4 1 Minimum Clearances To Combustible Construction...

Page 11: ...9 Figure 5 1 Wall Layout Mounting Hole Location...

Page 12: ...10 Figure 5 2 Boiler Mounting Bracket Installation Boiler Wall Mounting...

Page 39: ...37 FIGURE 7 24 SPLIT VENT SYSTEM FLEX IN ABANDONED MASONRY CHIMNEY VENT OPTIONS 33 38...

Page 63: ...61 This page is intentionally left blank...

Page 68: ...66 FIGURE 9 2 PIPING METHOD 1 NEAR BOILER PIPING HEATING ONLY...

Page 72: ...70 FIGURE 9 6 PIPING METHOD 1 NEAR BOILER PIPING SHADED BOILER LOOP...

Page 82: ...80 FIGURE 10 4 PROPER INSTALLATION OF HEADER SENSOR...

Page 84: ...82 FIGURE 10 6 INTERNAL WIRING CONNECTIONS DIAGRAM...

Page 85: ...83...

Page 92: ...90 Lighting and Operating Instructions...

Page 101: ...99 FIGURE 12 5 SETTINGS MENU SEE PART C FOR ADDITIONAL INFORMATION...

Page 113: ...111 FIGURE 13 2 IGNITION ELECTRODE GAP FIGURE 13 3 CONDENSATE TRAP EXPLODED PARTS VIEW...

Page 125: ...123...

Page 127: ...125 40 33 31 27 28 34 35 37 38 32 39 36 29 30 48 Blower Gas Valve Assembly for 80 100 120...

Page 129: ...127...

Page 131: ...129...

Page 132: ...130...

Page 133: ...131...

Page 135: ...133...

Page 137: ...135 140 141 142 143 144 145...