73

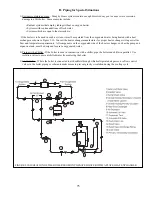

C: Standard Piping Installation Requirements

Observe the following requirements when installing the boiler piping:

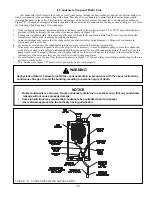

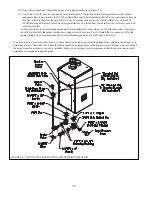

1) Relief Valve (Required) – The relief valve is shipped loose and must be installed in the location shown in Figure

\ %# &$&# %) && ( ##

valve be installed above the heat exchanger as shown. Pipe the outlet of the relief valve to a location where water

or stream will not create a hazard or cause property damage if the valve opens. The end of the discharge pipe must

terminate in unthreaded pipe. If the relief valve discharge is not piped to a drain, it must terminate at least 6” above

##& #% %#%## { %$# #

valve must be in an area where it is not likely to become plugged by debris.

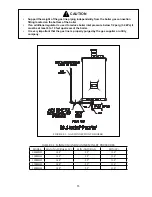

The relief valve supplied with the boiler is set to open at 30 psi. If it is replaced, the replacement must have

a setting less than or equal to the maximum allowable working pressure (MAWP) shown on the ASME data plate

located on the left side of the heat exchanger behind the service access panel (Figure 9.9).

2) Gauge (Required) - Indicates supply water pressure and temperature. This gauge is shipped loose. Install it as shown

in

Figure

9.9.

3) Circulator (required) – The boiler loop circulator is factory installed inside the boiler cabinet. Usually at least

one addition circulator (not supplied) will be required for the system to work properly. See the previous section for

more

information.

4) Expansion Tank (required) – If this boiler is replacing an existing boiler with no other changes in the system,

the old expansion tank can generally be reused. If the expansion tank must be replaced, consult the expansion tank

| { %

` ^ )_( &` # ))&\)) &

&&& '#$# & #)) #

expansion

tank.

6) Automatic Air Vent (required) – At least one automatic air vent is required. Manual air vents will usually be required

##) & %

7)

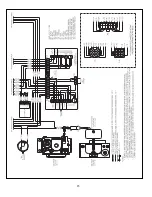

Manual Reset High Limit (required by some codes) - This control is required by ASME CSD-1 and some

other codes. Install the high limit in the boiler supply piping just above the boiler with no intervening valves. Set

the manual reset high limit to 200°F. Wire the limit per Figure 10.2 in the Wiring section.

8) Isolation Valves (recommended) - Isolation valves are useful when the boiler must be drained, as they will eliminate

#) %& &#

9) Strainer (recommended) – Install a Y Strainer, or other suitable strainer, to prevent any system debris from entering

# & %#'%~# #) % &\'# #

# # #( &' &&

"&

+B<>

z

%BAA?BA*()-

z

AAA."%?

B

z

AAAA-

z

AAB *-

z

B(AA-

Summary of Contents for PHNTM080

Page 2: ......

Page 9: ...7 Figure 4 1 Minimum Clearances To Combustible Construction...

Page 11: ...9 Figure 5 1 Wall Layout Mounting Hole Location...

Page 12: ...10 Figure 5 2 Boiler Mounting Bracket Installation Boiler Wall Mounting...

Page 39: ...37 FIGURE 7 24 SPLIT VENT SYSTEM FLEX IN ABANDONED MASONRY CHIMNEY VENT OPTIONS 33 38...

Page 63: ...61 This page is intentionally left blank...

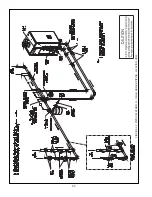

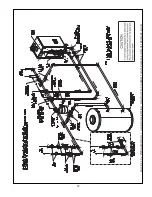

Page 68: ...66 FIGURE 9 2 PIPING METHOD 1 NEAR BOILER PIPING HEATING ONLY...

Page 72: ...70 FIGURE 9 6 PIPING METHOD 1 NEAR BOILER PIPING SHADED BOILER LOOP...

Page 82: ...80 FIGURE 10 4 PROPER INSTALLATION OF HEADER SENSOR...

Page 84: ...82 FIGURE 10 6 INTERNAL WIRING CONNECTIONS DIAGRAM...

Page 85: ...83...

Page 92: ...90 Lighting and Operating Instructions...

Page 101: ...99 FIGURE 12 5 SETTINGS MENU SEE PART C FOR ADDITIONAL INFORMATION...

Page 113: ...111 FIGURE 13 2 IGNITION ELECTRODE GAP FIGURE 13 3 CONDENSATE TRAP EXPLODED PARTS VIEW...

Page 125: ...123...

Page 127: ...125 40 33 31 27 28 34 35 37 38 32 39 36 29 30 48 Blower Gas Valve Assembly for 80 100 120...

Page 129: ...127...

Page 131: ...129...

Page 132: ...130...

Page 133: ...131...

Page 135: ...133...

Page 137: ...135 140 141 142 143 144 145...