65

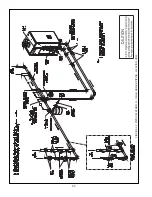

B. Near Boiler Piping Design

# ( ##''#%# ' # # #' $

# %''# #'\# |'' #&

)# %^'#%## *#* #'

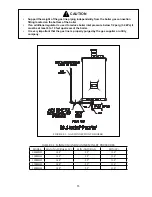

Table 9.1 can result in excessive noise or erosion damage to piping

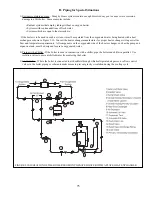

There are two basic methods that can be used to pipe this boiler into the system. Method #1 (primary-secondary

piping) is always preferred. Additional information on hydronic system design can be found in the

I=B=R

Guide RHH

published by the Air-Conditioning, Heating and Refrigeration Institute (AHRI).

Table 9.1: Flow Limitations

Flow (GPM)

Model

Minimum

Maximum

80MBH

5.0

13.3

100MBH

5.1

13.3

120MBH

6.2

13.3

150MBH

7.7

13.3

180MBH

9.3

13.3

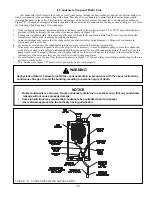

Method 1: Primary/Secondary Piping (Strongly Recommended)

This method can be used in heat-only applications as shown in Figure 9.2 or with an indirect water heater as shown

^ %^ %# \#'#%## _&`

&&#'#%##_ `#' %% & ##

' #)#( &'#' $%&#' ## %

`} % {# & % #& %'#%### %

as you would on any other heating system. All piping between the expansion tank and secondary connection tees must

&#' #& &&##\) &

& %# #&& &'#&¥#&

'#* &#&#

+` } % &' # '# #' & )#'( &$

9.1 provided both of the following conditions are met:

Q

% # # {

Q

$#( )%# % #

To verify that the 60ft, equivalent length is not exceeded, do the following:

` " % #& _##&& % ^ %`& %\&#

& \ \# % &' ## _##)&&`

` %$\&#( )%# % #&$#( )%#&

add them to the total length of planned straight pipe in the secondary loop.

c) The result is the total equivalent length of the planned boiler loop. If the equivalent length calculated in (b) is under

# #' $\# ' # )'& * (#

shown in this table. Otherwise, the equivalent length must be reduced.

Summary of Contents for PHNTM080

Page 2: ......

Page 9: ...7 Figure 4 1 Minimum Clearances To Combustible Construction...

Page 11: ...9 Figure 5 1 Wall Layout Mounting Hole Location...

Page 12: ...10 Figure 5 2 Boiler Mounting Bracket Installation Boiler Wall Mounting...

Page 39: ...37 FIGURE 7 24 SPLIT VENT SYSTEM FLEX IN ABANDONED MASONRY CHIMNEY VENT OPTIONS 33 38...

Page 63: ...61 This page is intentionally left blank...

Page 68: ...66 FIGURE 9 2 PIPING METHOD 1 NEAR BOILER PIPING HEATING ONLY...

Page 72: ...70 FIGURE 9 6 PIPING METHOD 1 NEAR BOILER PIPING SHADED BOILER LOOP...

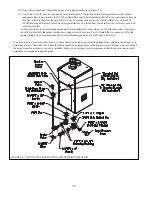

Page 82: ...80 FIGURE 10 4 PROPER INSTALLATION OF HEADER SENSOR...

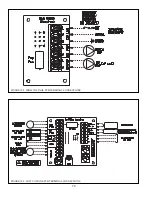

Page 84: ...82 FIGURE 10 6 INTERNAL WIRING CONNECTIONS DIAGRAM...

Page 85: ...83...

Page 92: ...90 Lighting and Operating Instructions...

Page 101: ...99 FIGURE 12 5 SETTINGS MENU SEE PART C FOR ADDITIONAL INFORMATION...

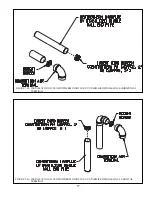

Page 113: ...111 FIGURE 13 2 IGNITION ELECTRODE GAP FIGURE 13 3 CONDENSATE TRAP EXPLODED PARTS VIEW...

Page 125: ...123...

Page 127: ...125 40 33 31 27 28 34 35 37 38 32 39 36 29 30 48 Blower Gas Valve Assembly for 80 100 120...

Page 129: ...127...

Page 131: ...129...

Page 132: ...130...

Page 133: ...131...

Page 135: ...133...

Page 137: ...135 140 141 142 143 144 145...