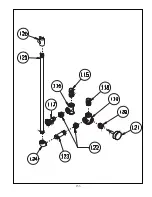

128

KEY

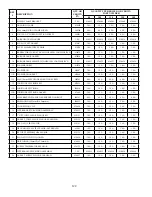

#

DESCRIPTION

QTY. OR

CROWN

PN

QUANTITY PER BOILER OR CROWN

PART NUMBER

80

100

120

150

180

51

GASKET, CONDENSATE TRAP

430105

1 EA

1 EA

1 EA

1 EA

1 EA

52

CONDENSATE TRAP BRACKET

430106

1 EA

1 EA

1 EA

1 EA

1 EA

53

CONDENSATE TRAP (INCLUDES 53A)

430100

1 EA

1 EA

1 EA

1 EA

1 EA

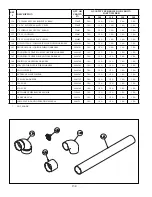

53A

CONDENSATE TRAP BALL

430101

1 EA

1 EA

1 EA

1 EA

1 EA

54

SILCONE TUBING (3/16” ID)

430061

1 EA

1 EA

1 EA

1 EA

1 EA

55

3/16” HOSE BARB FITTING

430065

1 EA

1 EA

1 EA

1 EA

1 EA

56

10-32 HEX FLANGE NUT

900248

1 EA

1 EA

1 EA

1 EA

1 EA

57

SILCONE TUBING (3/16” ID)

430062

1 EA

1 EA

1 EA

1 EA

1 EA

58

SUMP PRESSURE SWITCH

430109

1 EA

1 EA

1 EA

1 EA

1 EA

59

SILCONE TUBING (3/4” ID)

430063

1 EA

1 EA

1 EA

1 EA

1 EA

65

GASKET, SHORT, VESTIBULE FRAME

430400

2 EA

2 EA

2 EA

2 EA

2 EA

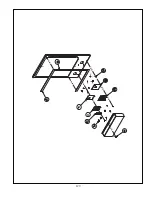

66

GASKET, LONG, VESTIBULE FRAME/CONTROL PANEL

430402

2 EA

2 EA

2 EA

2 EA

2 EA

67

5/16 OD x 1/4” SPACER

960054

8 EA

8 EA

8 EA

8 EA

8 EA

68

GASKET, LOW VOLTAGE PCB

430404

1 EA

1 EA

1 EA

1 EA

1 EA

69

LOW VOLTAGE PRINTED CIRCUIT BOARD

3503042

1 EA

1 EA

1 EA

1 EA

1 EA

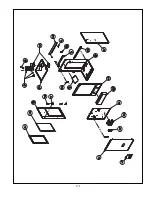

70

GASKET, LINE VOLTAGE PCB

430406

1 EA

1 EA

1 EA

1 EA

1 EA

71

LINE VOLTAGE PRINTED CIRCUIT BOARD

3503043

1 EA

1 EA

1 EA

1 EA

1 EA

72

PCB INSULATOR

430408

1 EA

1 EA

1 EA

1 EA

1 EA

73

#8-18 x 3/4” SCREW

900249

8 EA

8 EA

8 EA

8 EA

8 EA

74

#8-18 X 1/2” SELF TAPPING SCREW

900250

1 EA

1 EA

1 EA

1 EA

1 EA

75

TRANSFORMER

3502430

1 EA

1 EA

1 EA

1 EA

1 EA

76

HONEYWELL R7910B BOILER CONTROL KIT

433022

1 EA

1 EA

1 EA

1 EA

1 EA

77

THUMB SCREW, 8-32 x 13/32”

900251

2 EA

2 EA

2 EA

2 EA

2 EA

78

GASKET, WIRE PARTITION

430412

4 EA

4 EA

4 EA

4 EA

4 EA

79

#8-18 x 1/2” SELF TAPPING SCREW

900250

8 EA

8 EA

8 EA

8 EA

8 EA

80

PROGAMMED DISPLAY KIT

433060

1 EA

1 EA

1 EA

1 EA

1 EA

81

8-18 x 1/2” SELF TAPPING SCREW

900250

6 EA

6 EA

6 EA

6 EA

6 EA

82

CONTROL PANEL GASKET

430415

4 EA

4 EA

4 EA

4 EA

4 EA

83

GASKET, CABLE HOLDER

430416

3 EA

3 EA

3 EA

3 EA

3 EA

*

CABLE HOLDER ANCHOR MOUNT

430339

3 EA

3 EA

3 EA

3 EA

3 EA

*

NOT SHOWN

Summary of Contents for PHNTM080

Page 2: ......

Page 9: ...7 Figure 4 1 Minimum Clearances To Combustible Construction...

Page 11: ...9 Figure 5 1 Wall Layout Mounting Hole Location...

Page 12: ...10 Figure 5 2 Boiler Mounting Bracket Installation Boiler Wall Mounting...

Page 39: ...37 FIGURE 7 24 SPLIT VENT SYSTEM FLEX IN ABANDONED MASONRY CHIMNEY VENT OPTIONS 33 38...

Page 63: ...61 This page is intentionally left blank...

Page 68: ...66 FIGURE 9 2 PIPING METHOD 1 NEAR BOILER PIPING HEATING ONLY...

Page 72: ...70 FIGURE 9 6 PIPING METHOD 1 NEAR BOILER PIPING SHADED BOILER LOOP...

Page 82: ...80 FIGURE 10 4 PROPER INSTALLATION OF HEADER SENSOR...

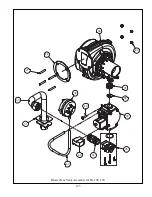

Page 84: ...82 FIGURE 10 6 INTERNAL WIRING CONNECTIONS DIAGRAM...

Page 85: ...83...

Page 92: ...90 Lighting and Operating Instructions...

Page 101: ...99 FIGURE 12 5 SETTINGS MENU SEE PART C FOR ADDITIONAL INFORMATION...

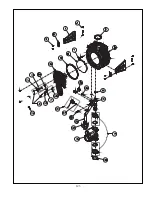

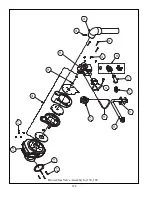

Page 113: ...111 FIGURE 13 2 IGNITION ELECTRODE GAP FIGURE 13 3 CONDENSATE TRAP EXPLODED PARTS VIEW...

Page 125: ...123...

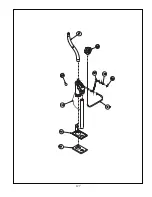

Page 127: ...125 40 33 31 27 28 34 35 37 38 32 39 36 29 30 48 Blower Gas Valve Assembly for 80 100 120...

Page 129: ...127...

Page 131: ...129...

Page 132: ...130...

Page 133: ...131...

Page 135: ...133...

Page 137: ...135 140 141 142 143 144 145...