5

$++;

MODEL*

MAXIMUM

INPUT

(MBH)

MINIMUM

INPUT

(MBH)

D.O.E.

HEATING

CAPACITY

(MBH)

AHRI NET

RATING*

(MBH)

WATER

VOLUME

(Gal.)

DIM “A”

SUPPLY &

RETURN

CONNECTION

SIZE (NPT)

GAS

CONNECTION

SIZE (NPT)

APPROX.

NET

WEIGHT

(lb)

PHNTM080

80

16

74

64

0.36

17”

1”

1/2”

100

PHNTM100

100

20

92

80

0.44

17”

1”

1/2”

102

PHNTM120

120

24

111

97

0.53

17”

1”

1/2”

105

PHNTM150

150

30

141

123

0.79

21”

1”

1/2”

119

PHNTM180

180

36

167

145

0.79

21”

1”

1/2”

119

* The Net AHRI Water Ratings shown are based on a piping and pickup allowance of 1.15. The manufacturer should be consulted before

selecting a boiler for installations having unusual piping and pickup requirements, such as intermittent system operation, extensive piping

systems, etc.

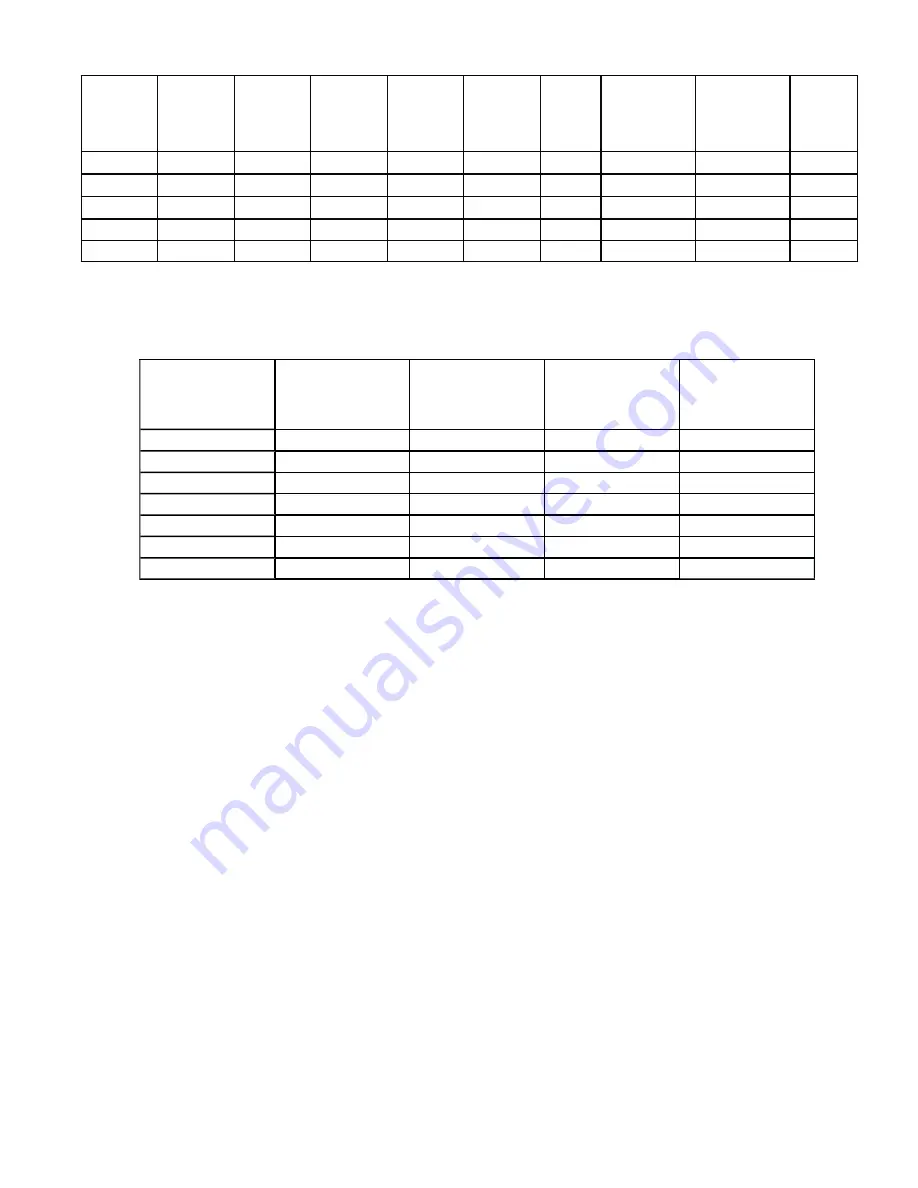

Table 2.3: Vent Lengths

MODEL

NOMINAL

VENT/INTAKE

SIZE (in)

MIN VENT

LENGTH (in)

MAX VENT

LENGTH

APPROX.

DERATE AT

MAX VENT

(%)

080

2

12

60ft

9

080

3

12

135ft

2

100

2

12

60ft

15

100

3

12

135ft

3

120

3

12

135ft

7

150

3

52

135ft

7

180

3

52

135ft

9

See Part VII (Venting) for additional requirements and details.

III Before Installing

1) Safe, reliable operation of this boiler depends upon installation by a professional heating contractor in strict accordance

with this manual and the requirements of the authority having jurisdiction.

Q

## #) %[ & \ &' ##

and the National Fuel Gas Code, ANSI Z223.1. In Canada, installation must be in accordance with the B149.1

Installation

Code.

Q

]#( &## #) %[ & \# #

Standard for Controls

and Safety Devices for Automatically Fired Boilers

(ANSI/ASME CSD-1).

2) Read Section VII to verify that the maximum combustion air and exhaust pipe lengths will not be exceeded in the

planned installation. Also verify that the vent terminal can be located in accordance with Section VII.

3) Make sure that the boiler is correctly sized:

Q

^# % %) & _&& `\ && { %

method such as the

I=B=R

Guide RHH published by the Air-Conditioning, Heating and Refrigeration Institute

(AHRI).

Q

^'& # %\#& %| { %% &

Q

^'# # & & '#\# ##&# &

'#|

Summary of Contents for PHNTM080

Page 2: ......

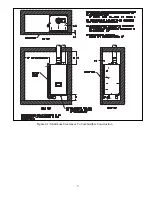

Page 9: ...7 Figure 4 1 Minimum Clearances To Combustible Construction...

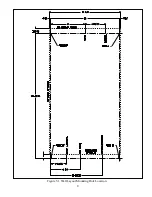

Page 11: ...9 Figure 5 1 Wall Layout Mounting Hole Location...

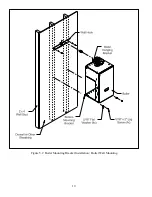

Page 12: ...10 Figure 5 2 Boiler Mounting Bracket Installation Boiler Wall Mounting...

Page 39: ...37 FIGURE 7 24 SPLIT VENT SYSTEM FLEX IN ABANDONED MASONRY CHIMNEY VENT OPTIONS 33 38...

Page 63: ...61 This page is intentionally left blank...

Page 68: ...66 FIGURE 9 2 PIPING METHOD 1 NEAR BOILER PIPING HEATING ONLY...

Page 72: ...70 FIGURE 9 6 PIPING METHOD 1 NEAR BOILER PIPING SHADED BOILER LOOP...

Page 82: ...80 FIGURE 10 4 PROPER INSTALLATION OF HEADER SENSOR...

Page 84: ...82 FIGURE 10 6 INTERNAL WIRING CONNECTIONS DIAGRAM...

Page 85: ...83...

Page 92: ...90 Lighting and Operating Instructions...

Page 101: ...99 FIGURE 12 5 SETTINGS MENU SEE PART C FOR ADDITIONAL INFORMATION...

Page 113: ...111 FIGURE 13 2 IGNITION ELECTRODE GAP FIGURE 13 3 CONDENSATE TRAP EXPLODED PARTS VIEW...

Page 125: ...123...

Page 127: ...125 40 33 31 27 28 34 35 37 38 32 39 36 29 30 48 Blower Gas Valve Assembly for 80 100 120...

Page 129: ...127...

Page 131: ...129...

Page 132: ...130...

Page 133: ...131...

Page 135: ...133...

Page 137: ...135 140 141 142 143 144 145...