MC012C-BS00 TRANSAXLE: HYDRAULIC AND PARK BRAKE SYSTEMS

Park Brake System

2006-2010 Turf/Carryall 272/472 and XRT 1200/1200 SE Maintenance and Service Manual

Page 6-33

6

PARK BRAKE SYSTEM

See General Warning, Section 1, Page 1-1.

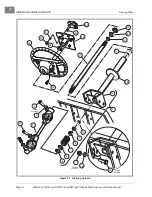

PARK BRAKE CABLE REMOVAL

Equalizer Cable Removal

1. Chock the wheels and release the park brake.

2. Remove the two screws (3) that secure the park brake boot (2) to the seat support

3. Slide the boot (2) off of the park brake handle (1).

4. Remove the boot shield (27) from the park brake handle.

5. Remove the equalizer spring (21) from the equalizer cable (9).

6. Remove the equalizer jam nut (11) and conical nut (23) from the cable end (9).

7. Remove the end of the park brake cable from handle (1) by pushing the equalizer cable in an upward

direction and pulling the cable end toward the passenger side of the vehicle.

8. Remove the equalizer cable from the vehicle.

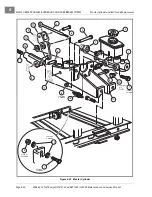

Park Brake Pulley Removal

1. Remove the park brake equalizer cable.

See Park Brake Cable Removal on page 6-33.

2. Remove the four #10-24 x 3/4-inch socket-head screws (14), locknuts (18) and washers (17) from frame

and remove the assembly

Wheel Brake Cable Removal

1. Loosen the equalizer jam nut (11) and the conical nut (23) to provide slack in the wheel brake cables

.

2. Pull a wheel brake cable to the side and remove the cable end from the keyhole opening in the park brake

equalizer

(Figure 6-25, Page 6-34 and Figure 6-26, Page 6-34)

.

3. Remove the cable clip (23) from a wheel brake cable (22) at the vehicle frame (25)

4. Remove a park brake cable clip (12), hair spring cotter pin (20) and clevis pin (19).

5. Remove the cable from a cable support bracket (16 or 24).

6. Slide the cable through the frame hanger (15) and remove the cable from the vehicle.

7. Remove the remaining wheel brake cable in the same manner.

Figure 6-24 Master Cylinder Reservoir

WAR

NING

USE ONL

Y

DO

T 3 FLUID

FR

OM A

SEALED

CONT

AINER

MAX

MIN

USE

O

N

L

Y

D

.

O

.

T

. 3

F

LU

ID

F

RO

M

A

S

E

A

L

E

D

CLEAN

F

IL

L

E

R

C

A

PS

B

EF

OR

E

MIN

MAX

Full

Level

Low

Level

Safe Level

Summary of Contents for CARRYALL 272

Page 2: ......

Page 14: ......

Page 18: ...1...

Page 52: ...5...

Page 90: ...6...

Page 110: ...7...

Page 112: ...8...

Page 128: ...10...

Page 170: ...11...

Page 224: ...13...

Page 284: ...16...

Page 302: ...17...

Page 308: ......

Page 309: ...Club Car R NOTES...

Page 310: ...Club Car R NOTES...

Page 311: ......