ELECTRICAL COMPONENTS: FE400, KEY-START ENGINE

Starter/Generator (Model 114-01-4005)

Page 12-16

2006-2010 Turf/Carryall 272/472 and XRT 1200/1200 SE Maintenance and Service Manual

12

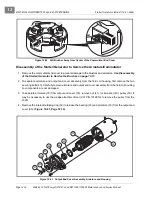

Field Coil Assembly

1. Replace entire field coil housing assembly if coils, pole shoes or terminals are damaged.

Visual Inspection of Armature

Obvious defects can be seen by examining the armature. If an armature has frayed or charred insulation, bro-

ken wires or thrown solder, it is obvious without testing that it should be replaced. Faults seen during the

visual inspection can aid in diagnosing the original cause of the failure. Items to look for are listed below.

•

Burned, charred, or cracked insulation

•

Improperly cured varnish

•

Thrown solder

•

Flared armature windings

•

Worn, burned, or glazed commutator

•

Loose or raised commutator bars

•

Bruised or damaged armature core laminations

•

Worn armature bearing or shaft

•

Dirty or oily commutator

Commutator Cleaning and Inspection

1. Clean the carbon dust, dirt and oil from the commutator. Visually inspect the commutator for worn,

burned or glazed areas. Check for loose or raised commutator bars. Slight roughness of the commutator

can be polished away with 400 grit (or finer) sandpaper.

See following CAUTION.

Figure 12-24 Field Coil Assembly

7

2

2

5

4

3

1

6

7

Summary of Contents for CARRYALL 272

Page 2: ......

Page 14: ......

Page 18: ...1...

Page 52: ...5...

Page 90: ...6...

Page 110: ...7...

Page 112: ...8...

Page 128: ...10...

Page 170: ...11...

Page 224: ...13...

Page 284: ...16...

Page 302: ...17...

Page 308: ......

Page 309: ...Club Car R NOTES...

Page 310: ...Club Car R NOTES...

Page 311: ......