8-36

62-11039

8.24.2 Electronic Defrost Timer

Refer to Section 2.12 for description.

8.25 CHECKING CALIBRATION OF

DEFROST AIR SWITCH

2

1

3

6

5

4

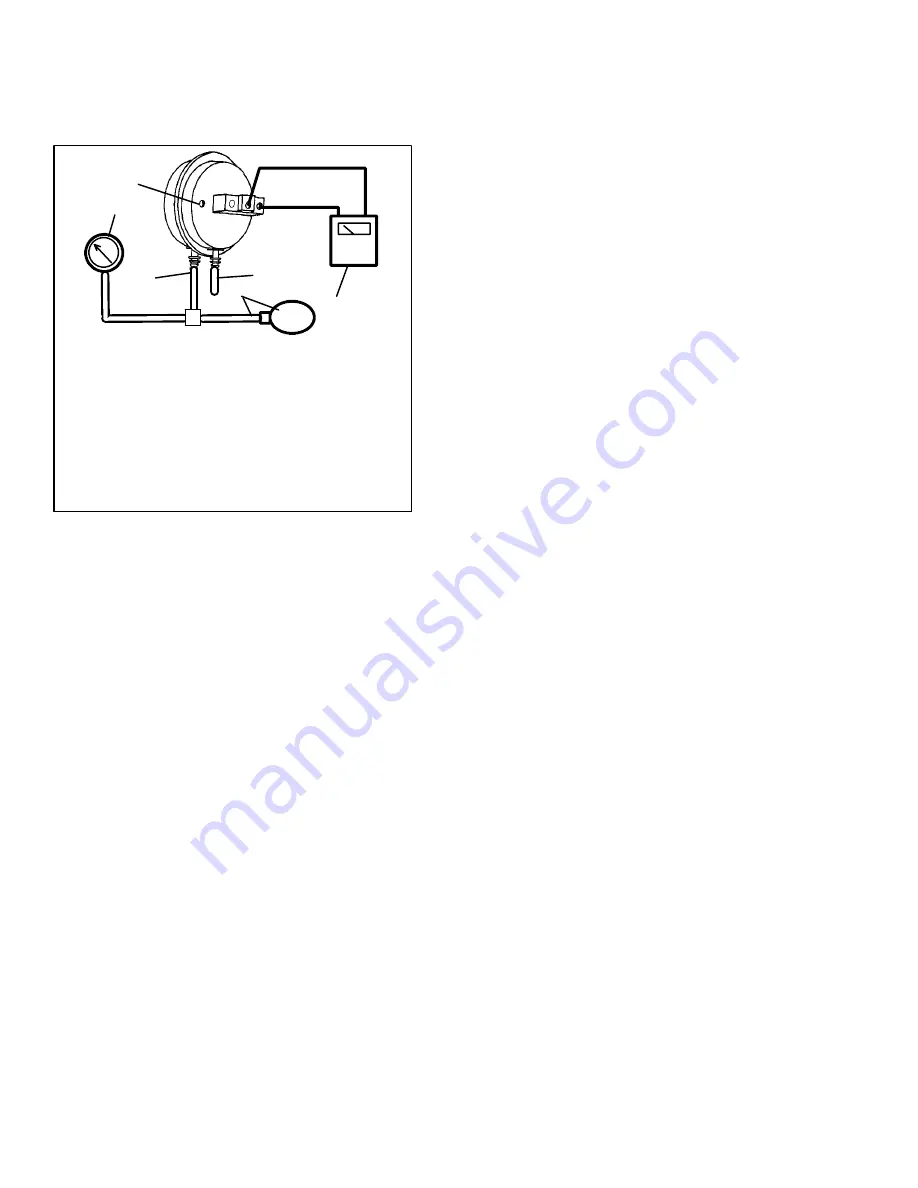

1. Ohmmeter or Continuity Device

2. Adjustment Screw (0.050” socket head

size)

3. Low Side Connection

4. Pressure Line or Aspirator Bulb (P/N

07-00177-01)

5. Magnehelic Gauge (P/N 07-00177-00)

6. High Side Connection

Figure 8--36 Defrost Air Switch Test Setup

a. Make sure magnehelic gauge is in proper calibra-

tion.

NOTE

The Magnehelic Gauge may be used in any

position, but must be re-zeroed if position of

gauge is changed from vertical to horizontal or

vice versa. USE ONLY IN POSITION FOR

WHICH IT IS ZEROED. The Defrost Air Switch

MUST be in the same orientation as it will be in

when installed in the unit.

b. With air switch in vertical position, connect high pres-

sure side of magnehelic gauge to high side connec-

tion of air switch. (See Figure 8--36)

c. Install tee in pressure line to high side connection. Tee

should be approximately half-way between gauge and

air switch or an improper reading may result.

d. Attach an ohmmeter to the air switch electrical con-

tacts to check switch action.

NOTE

Use a hand aspirator (P/N 07-00177-01), since

blowing into tube by mouth may cause an incor-

rect reading.

e. With the gauge reading at zero, apply air pressure

very slowly to the air switch. An ohmmeter will indi-

cate continuity when switch actuates. The switch

contacts should close and the ohmmeter needle

move rapidly to 0. Any hesitation in the ohmmeter

indicates a possible problem with the switch, and it

should be replaced.

f. Refer to Section 2.12 for switch settings. If switch fails

to actuate at correct gauge reading, adjust switch by

turning adjusting screw clockwise to increase setting or

counterclockwise to decrease setting.

g. Repeat checkout procedure until switch actuates at

correct gauge reading.

h. After switch is adjusted, place a small amount of

paint or fingernail polish on the adjusting screw so

that vibration will not change switch setting.

8.26 EVAPORATOR COIL

8.26.1 Cleaning

The use of recycled cardboard cartons is increasing

across the country. The recycled cardboard cartons

create much more fiber dust during transport than “new”

cartons. The fiber dust and particles are drawn into the

evaporator where they lodge between the evaporator

fins. If the coil is not cleaned on a regular basis,

sometimes as often as after each trip, the accumulation

can be great enough to restrict air flow, cause coil icing,

repetitive defrosts and loss of unit capacity. Due to the

“washing” action of normal defrost the fiber dust and

particles may not be visible on the face of the coil but

may accumulate deep within.

It is recommended to clean the evaporator coil on a

regular basis, not only to remove cardboard dust, but to

remove any grease or oil film which sometimes coats

the fins and prevents water from draining into the drain

pan.

Cardboard fiber particles after being wetted and dried

several times can be very hard to remove. Therefore,

several washings may be necessary.

a. Remove rubber check valves (Kazoo) from drain

lines (front of trailer or rail car).

b. Spray coil with a mild detergent solution such as

Oakite 164 or 202) or any good commercial grade au-

tomatic dish washer detergent such as Electrosol or

Cascade and let the solution stand for a few minutes

and reverse flush (opposite normal air flow) with clean

water at mild pressure. A garden hose with spray

nozzle is usually sufficient. Make sure drain lines are

clean.

c. Run unit until defrost mode can be initiated to check

for proper draining from drain pan.

8.26.2 Coil Replacement -- Compartment 1

a. Pump unit down. (Refer to section 8.10)

b. With power OFF and power plug removed, remove

the screws securing the panel covering the evapora-

tor section.

c. Disconnect all heater wiring.

d. Disconnect the RAT, DTT, and SAT sensors from the

coil.

e. Remove the mounting hardware from the coil.

f. Unsolder the two coil connections, one at the distrib-

utor and the other at the coil header.

g. After defective coil is removed from unit, remove

heaters and install on replacement coil.

h. Install coil assembly by reversing above steps.

i. Leak check connections per section 8.11. Evacuate

the unit per section 8.12 and add refrigerant charge

per Section 8.12.4.

Summary of Contents for VECTOR 1800 MT

Page 1: ......

Page 2: ...OPERATION SERVICE MANUAL for VECTOR 1800 MT Trailer Multi Temp Refrigeration Units ...

Page 19: ...1 5 62 11039 1 3 SAFETY DECALS ...

Page 20: ...1 6 62 11039 62 03958 00 Heat Warning 62 03957 01 High Voltage 62 60280 00 Standby Safety ...

Page 21: ...1 7 62 11039 ...

Page 303: ...10 1 62 11039 ...

Page 310: ...10 8 62 11039 BASED ON ENGINEERING SCHEMATIC 62 60926 REV G NEXT SHT ...

Page 311: ...10 9 62 11039 FROM PREVIOUS SHT ...